Packaging device and buffer

a packaging device and buffer technology, applied in packaging, sustainable manufacturing/processing, large containers, etc., can solve the problems of increasing plastic waste including waste of pet bottles, harmful substances can remain in burnt ashes after incineration, and the recycling ratio has not been so high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

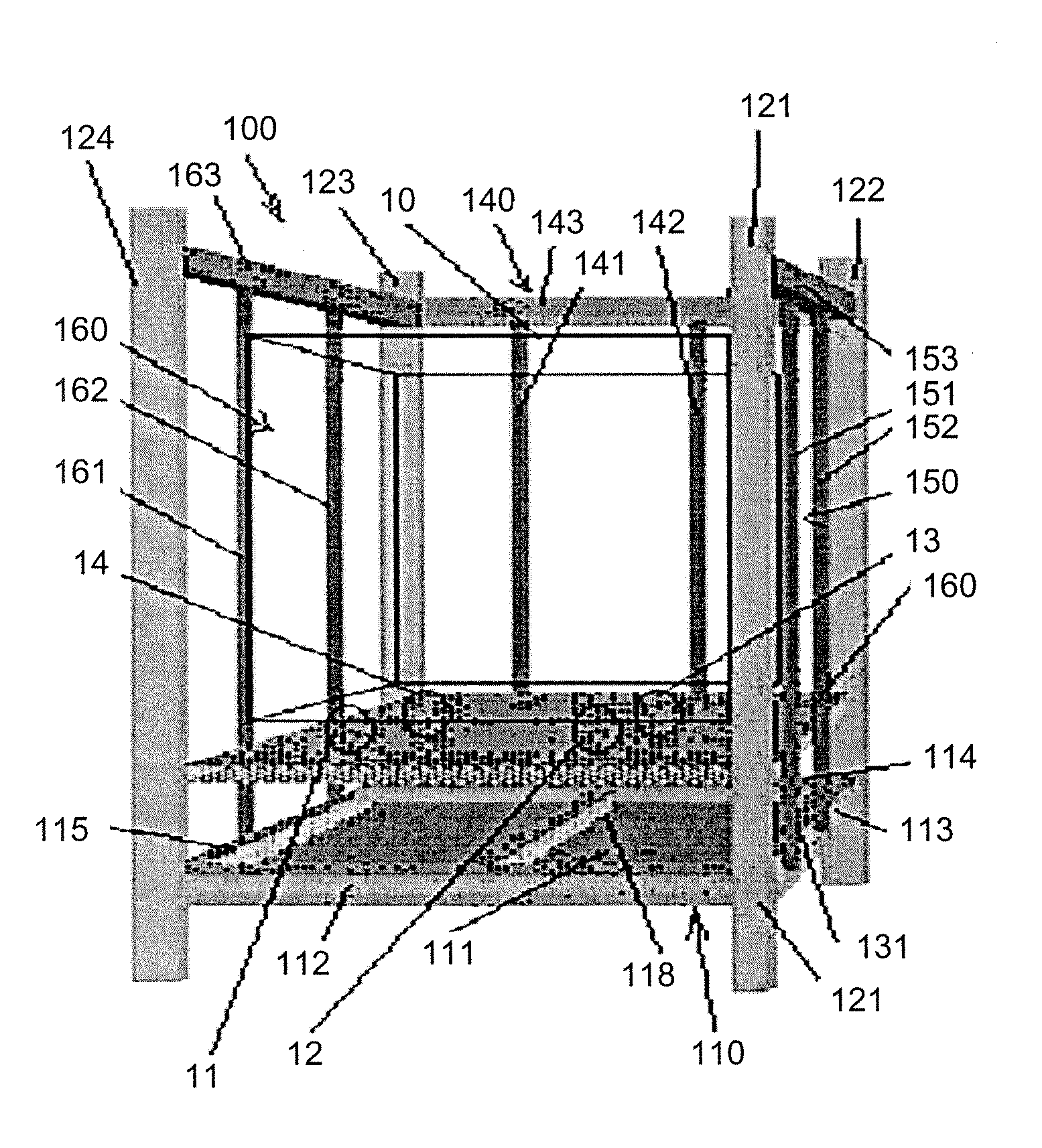

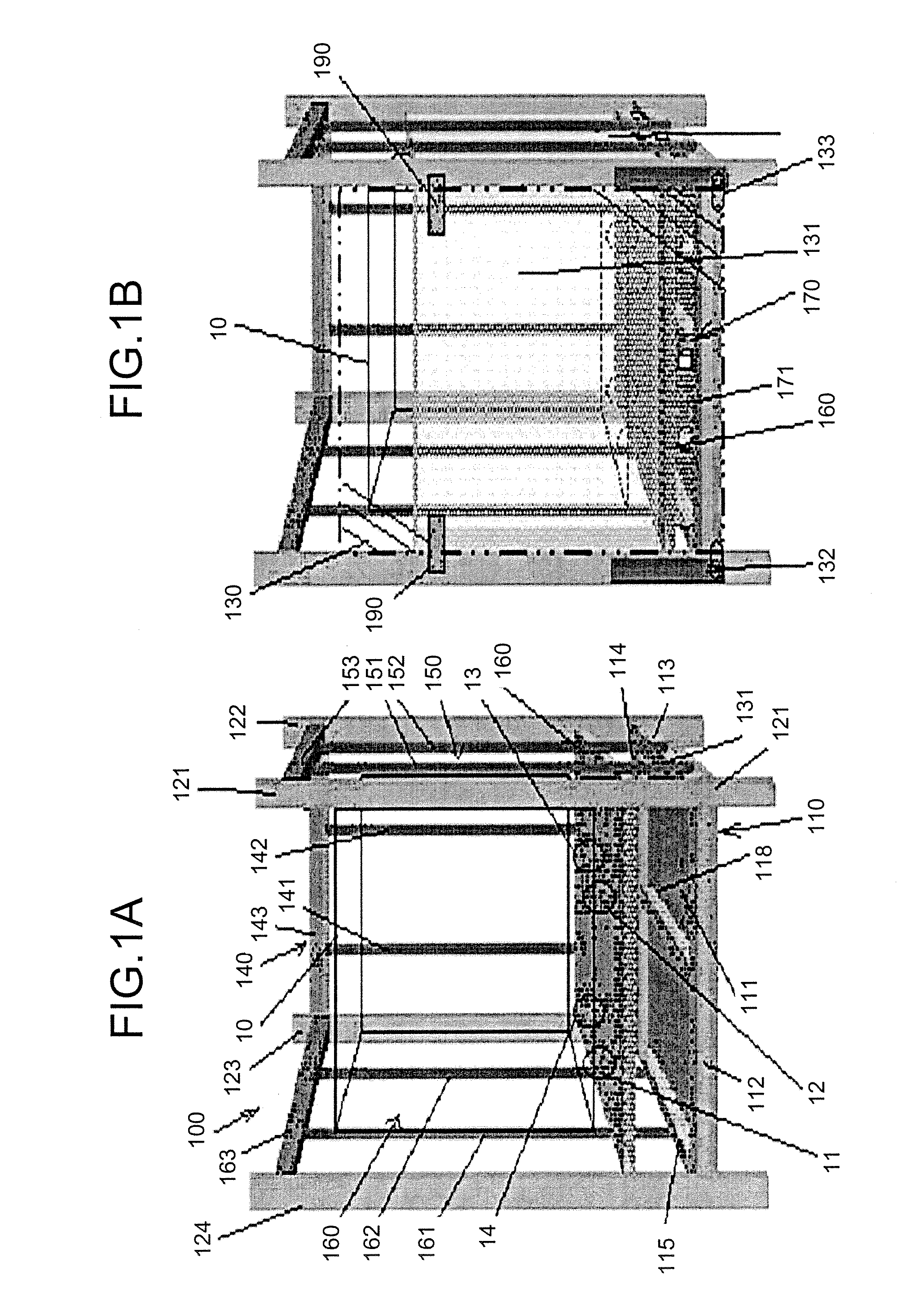

[0053] A packaging device 100 is for packaging a product 10, and as shown in FIGS. 1A and 1B, four casters 11, 12, 13, and 14 are fitted to the product 10. The packaging device 100 includes a bottom base 110, four support members 121, 122, 123, and 124 arranged upright on four corners of the bottom base 110, and also serving as legs of the bottom base 110, a front member 130 detachably fitted to the bottom base 110 and forming a front wall, a rear member 140 fitted to the bottom base 110 and forming a rear wall, a side member 150 fitted to the bottom base 110 and forming a right wall, a side member 160 forming a left wall, a buffer member 170 arranged on the bottom base 110 and formed of PET-bottles 171, which are multiple sealed containers containing a gas sealed therein, and a mounting base 180 arranged on the buffer member 170, on which an article is mounted.

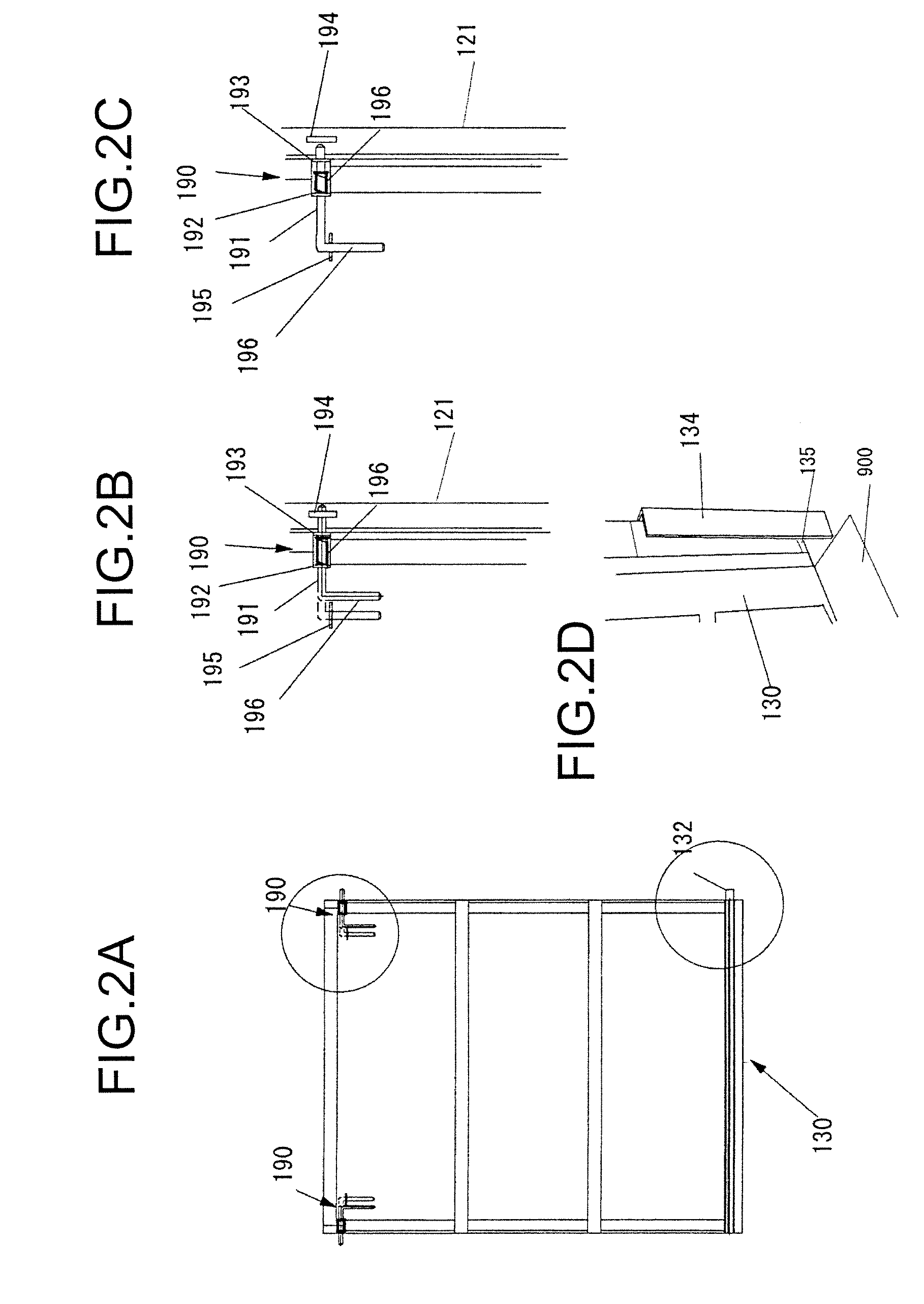

[0054] The packaging device 100 according to this embodiment includes locking devices 190, which fix the front member 130 ...

second embodiment

[0096] In the bottom base 210, as shown in FIGS. 17, 18, and 19, frames 212, 213, 214, and 215 are arranged on four sides of a rectangular plate member 211, and reinforcing members 217 and 218 are arranged on the underside of the plate member 211 in a pattern in the shape of a well crib. legs 261, 262, and 263 are arranged below the bottom base 210, to form a fork inserting portion of the forklift. Reference numeral 236 in FIG. 19 denotes a reinforcing corner plate.

[0097] According to the second embodiment, pillar members include lower pillar members 231, 232, 233, and 234 arranged on the bottom base 210, and two pairs of, in total four, upper pillar members 241 and 242 (since two upper pillar members constituting the right side member are not shown in FIG. 19, reference numerals thereof are omitted) constituting the upper side members 240 to be detachably provided thereon.

[0098] Left and right side members are respectively formed of the lower side member 230 provided between the ...

third embodiment

[0108] as shown in FIG. 24, the buffer 300 arranged between two side members of the packaging device and the article is used as the buffer. As the buffer 300, a plurality of PET-bottles 330, which are airtight containers, with a gas being sealed in a hollow box member 310, are arranged along the apparatus with the caps being arranged upward. According to this configuration, the bodies of the PET-bottles in the buffer 300 can absorb the impacts from the side of the packaging device, with respect to lateral vibrations.

[0109] According to an embodiment of the present invention, not only the impact against the article, which occurs during transportation, can be alleviated by the buffer, but also the packaging device can be used repeatedly. Accordingly, the investment for plant and equipment, the cost, and the time of packaging can be reduced, and parts control can be facilitated. Furthermore, the PET-bottles are not disposed of as a waste and can be reused, fixation and releasing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com