Heat retaining wetsuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

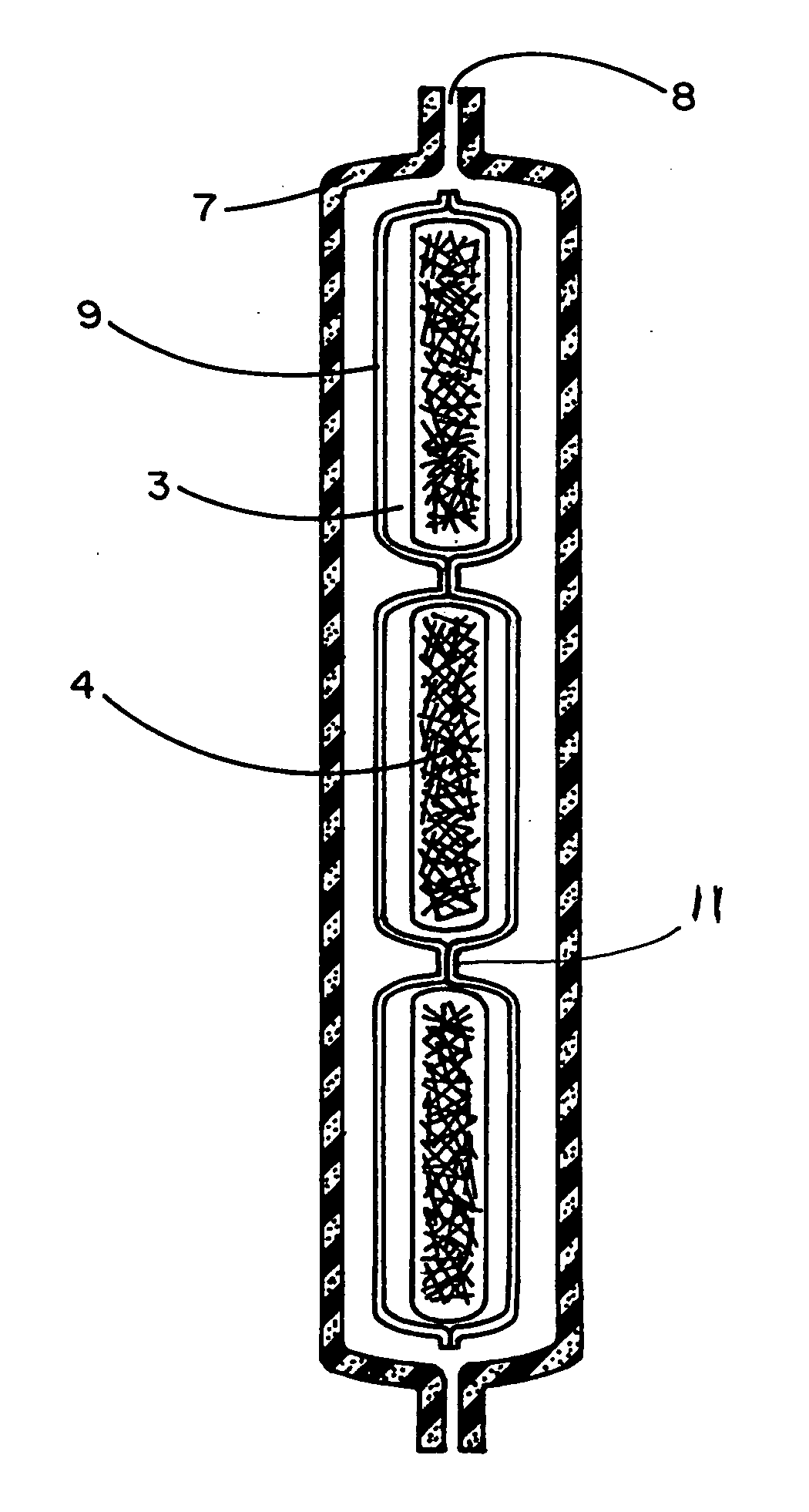

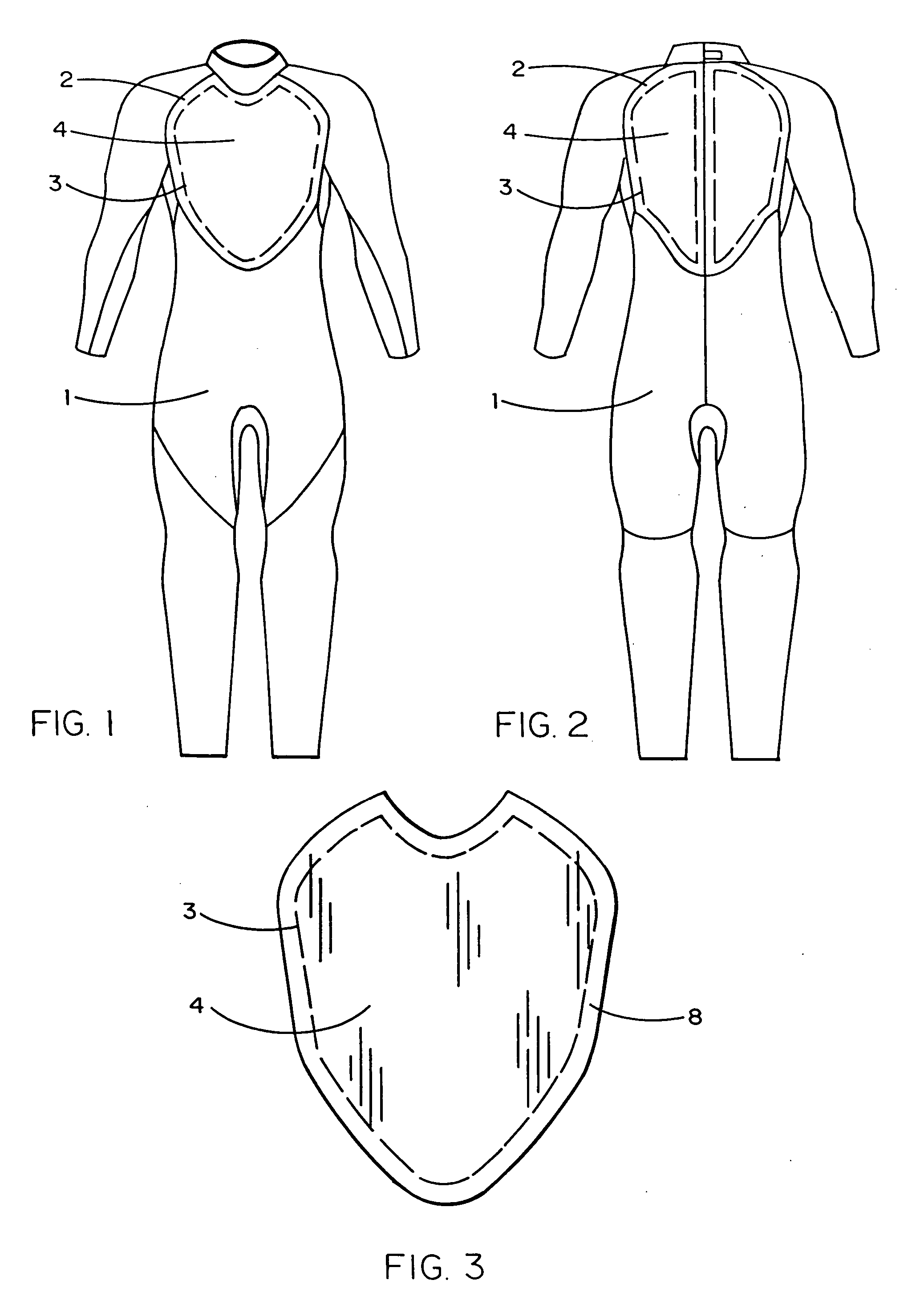

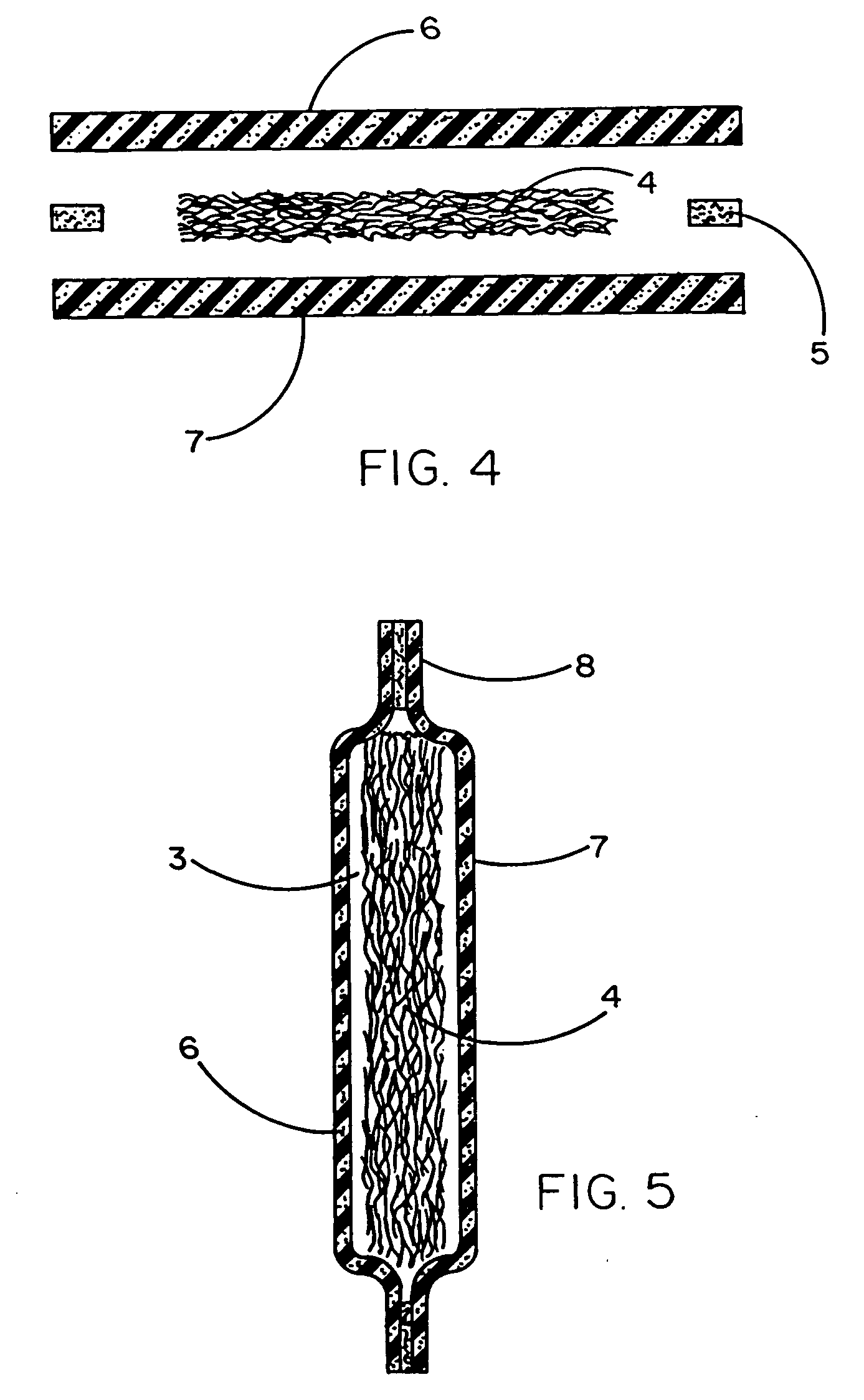

[0021] Referring to the accompanying drawings, it will be seen in FIGS. 1 through 5 that in a preferred embodiment of the present invention, a wetsuit comprises two layers of a sponge-like material, namely, layer 6 and layer 7. These sponge layers may or may not have a fabric-covered surface. In the wetsuit 1 shown in FIG. 1, most of the regions of the two layers of sponge material are glued together using glue 5 to form a laminated wetsuit configuration. However, in one or more selected regions 2 (i.e., chest, left back, right back, etc.) the two layers of sponge material are left unglued and thus free to separate from one another to form an air chamber 3 surrounded by a glued border 8.

[0022] In the preferred embodiment shown herein, these air chambers are filled with a low density stuffing material 4. This material will preferably have a density of 0.02˜0.05 mg / cm3 such as can be achieved using a multi-layered fiber structure (i.e., layered cotton fiber, synthetic fiber or the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com