System, method, and apparatus for railroad turnout and derail lift frog

a technology of turnout and derailment, applied in the field of system, method and apparatus of railroad turnout lift frog, can solve the problems of increased contact pressure of the wheel, wear and tear of the frog, and not being economical to repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

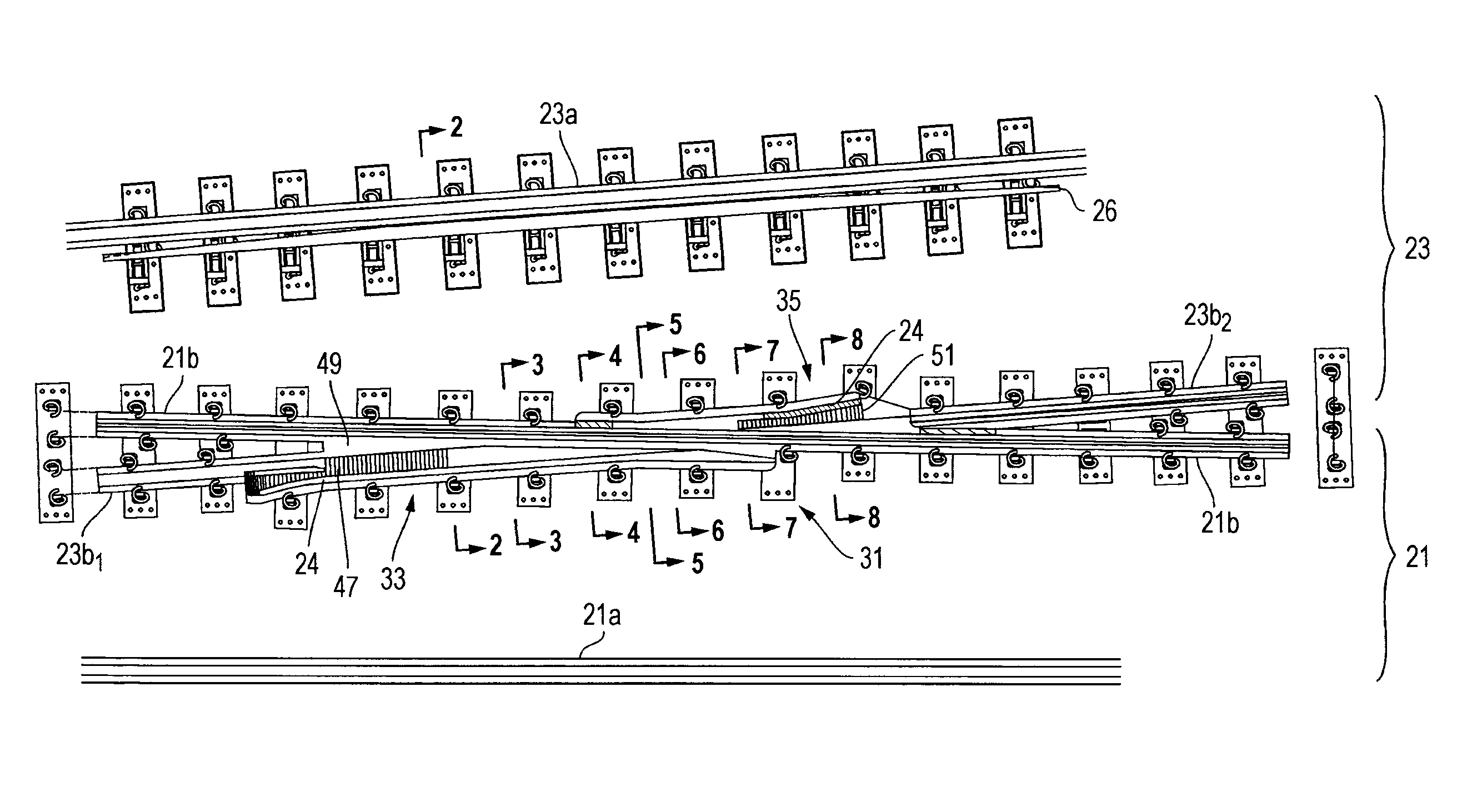

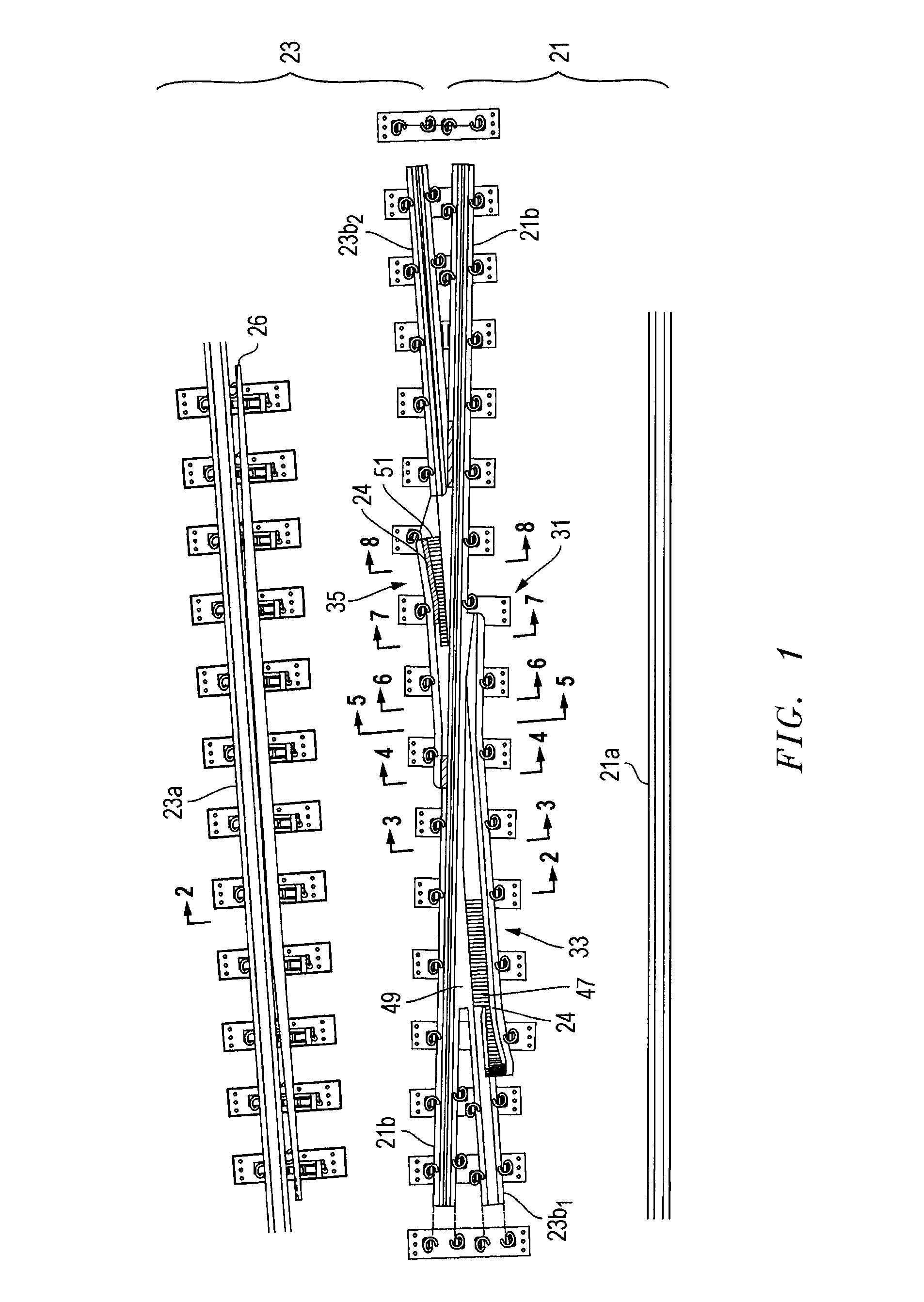

[0023] Referring to FIG. 1, a main track 21 and a side track 23 are shown crossing each other. For ease of reference, the two rails of main track 21 are labeled outside main rail 21a and inside main rail 21b. Similarly, the two rails of side track 23 are described as outside side rail 23a, and inside side rail 23b. For simplicity, the illustrated embodiment of FIG. 1 depicts the inside side rail 23b crossing the inside main rail 21b from left to right. However, those skilled in the art will recognize that the present invention is readily adaptable for crossings by other rails in both directions as is commonly known in the art of railroad frogs.

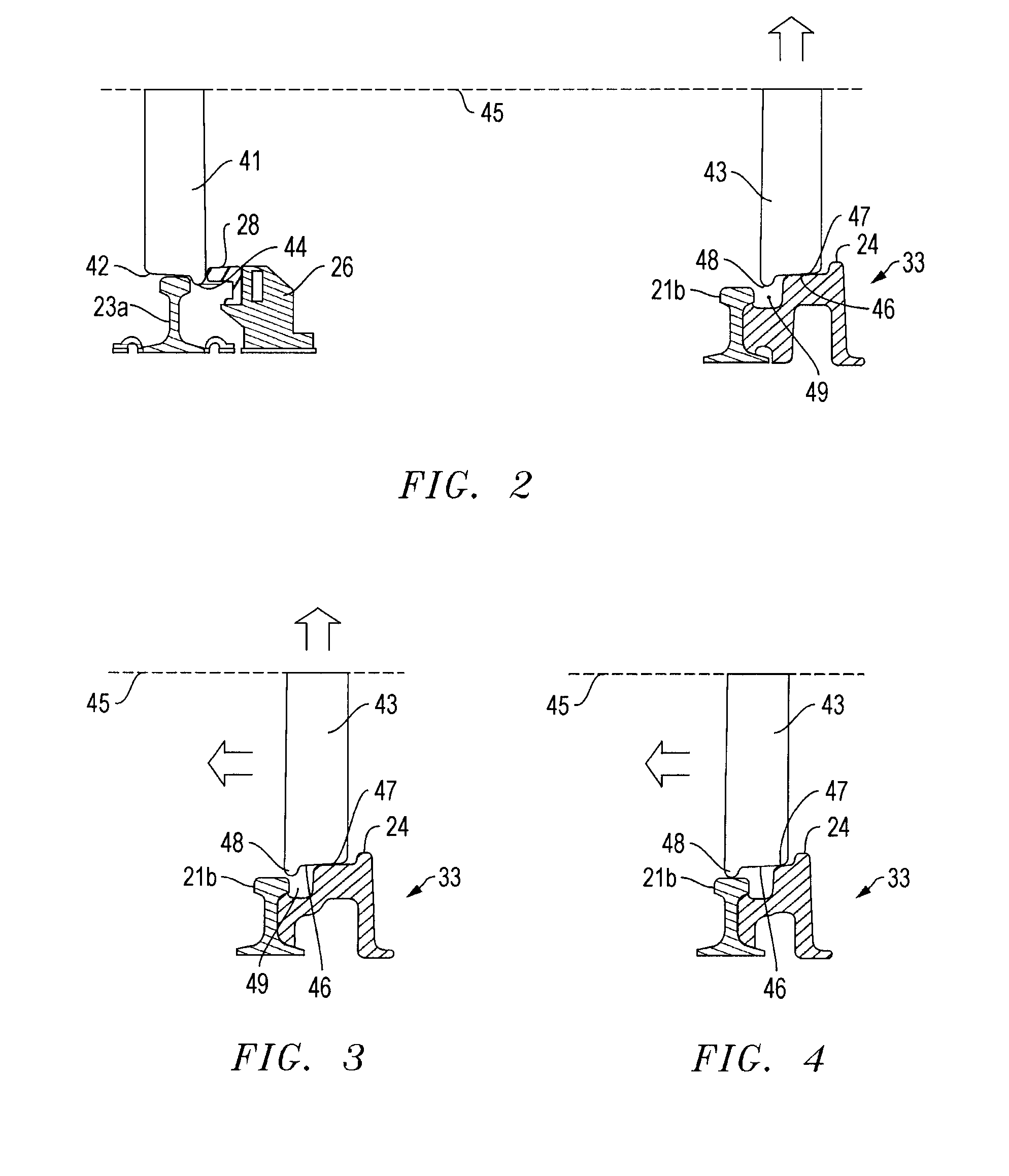

[0024] A frog 31 is located at the illustrated crossing to accommodate the transition of a train on the side track 23 past the main track 21. The main track 21 extends continuously through the frog 31. However, the inside side rail 23b is segmented into two separate pieces 23b1, 23b2 that are separated by both the frog 31 and the unbroken ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com