Method of manufacturing stone veneers

a technology of stone veneers and veneers, which is applied in the field of stone masonry, can solve the problems of reducing the production efficiency of veneers or pavers, and reducing the production efficiency of stone veneers. the effect of maximizing the output of such corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

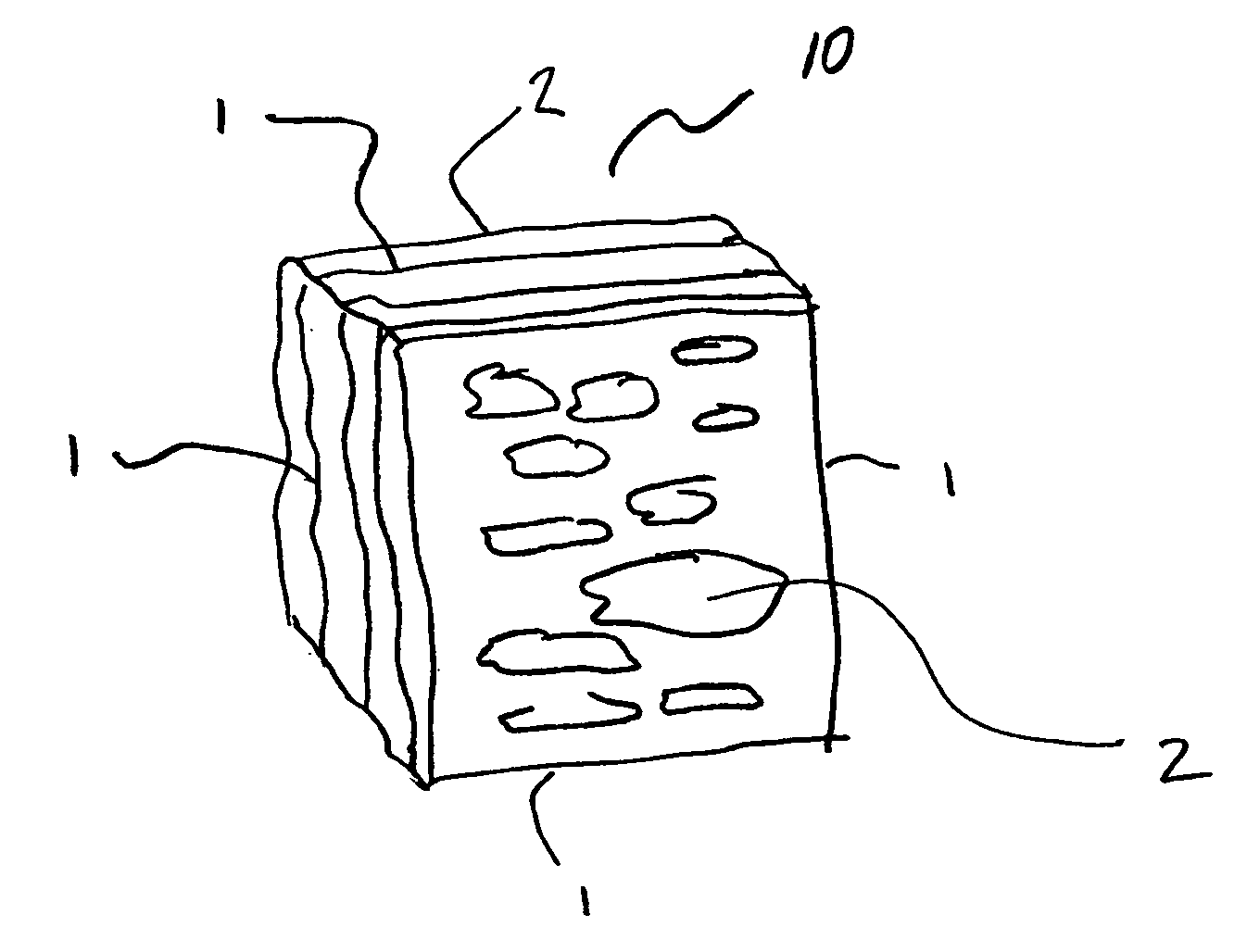

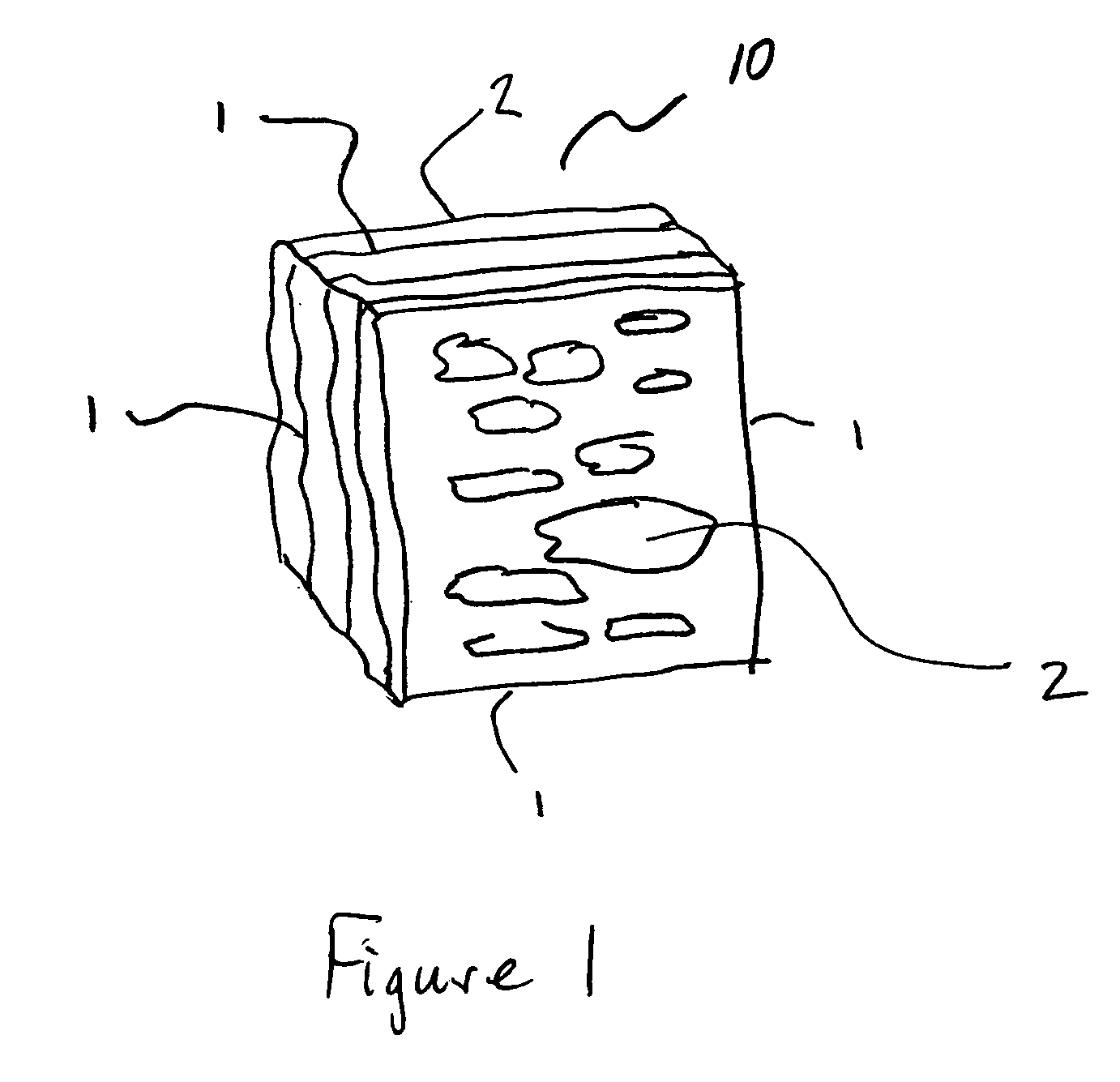

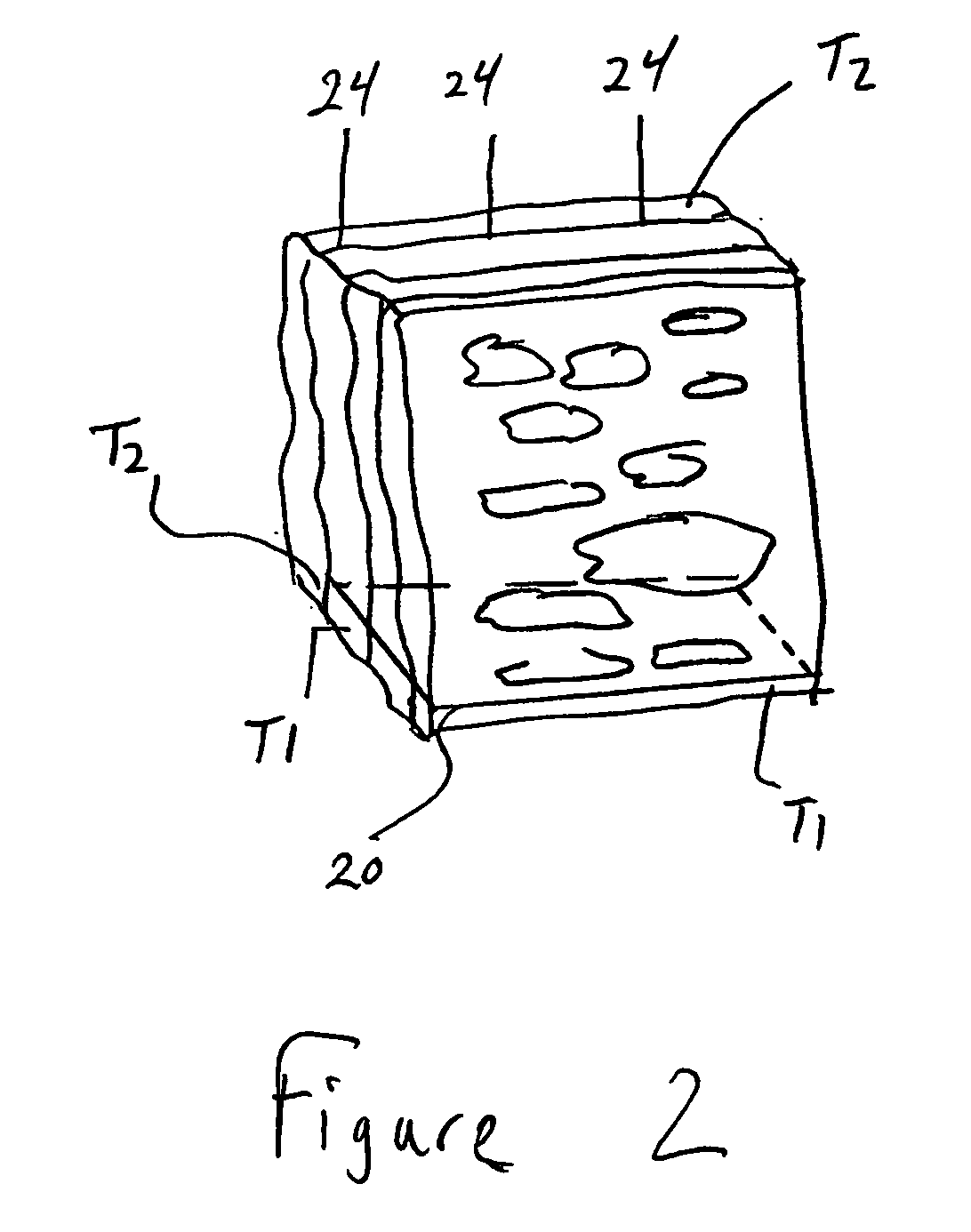

[0024] Referring now to FIG. 1, a typical stone is shown at 10. The side grain or ashler faces are indicated at 1 and the split face is indicated at 2. A presently preferred embodiment of the invention is shown in FIGS. 2 and 3, in which veneer corners 30 of thickness T1 and T2 are produced by making a cut 20 into the stone across the split face 2 to a depth equal to the thickness of the stone, less T1, a desired thickness of the veneer corner, and then splitting the stone from the side planar with the cut, but furthest from it, along a plane 24, distance T2, a desired thickness of the veneer corner, typically, but not necessarily, equal to T1, from the face of the stone opposite the side from which the first cut was made. This process may be repeated a number of times with the remaining stone 34.

[0025] In another presently preferred embodiment, the splitting can be replaced by a second cut along plane 24 that terminates before intersecting the first cut 20. The created overhang su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inside angle | aaaaa | aaaaa |

| inside angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com