Attachable heat radiating panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

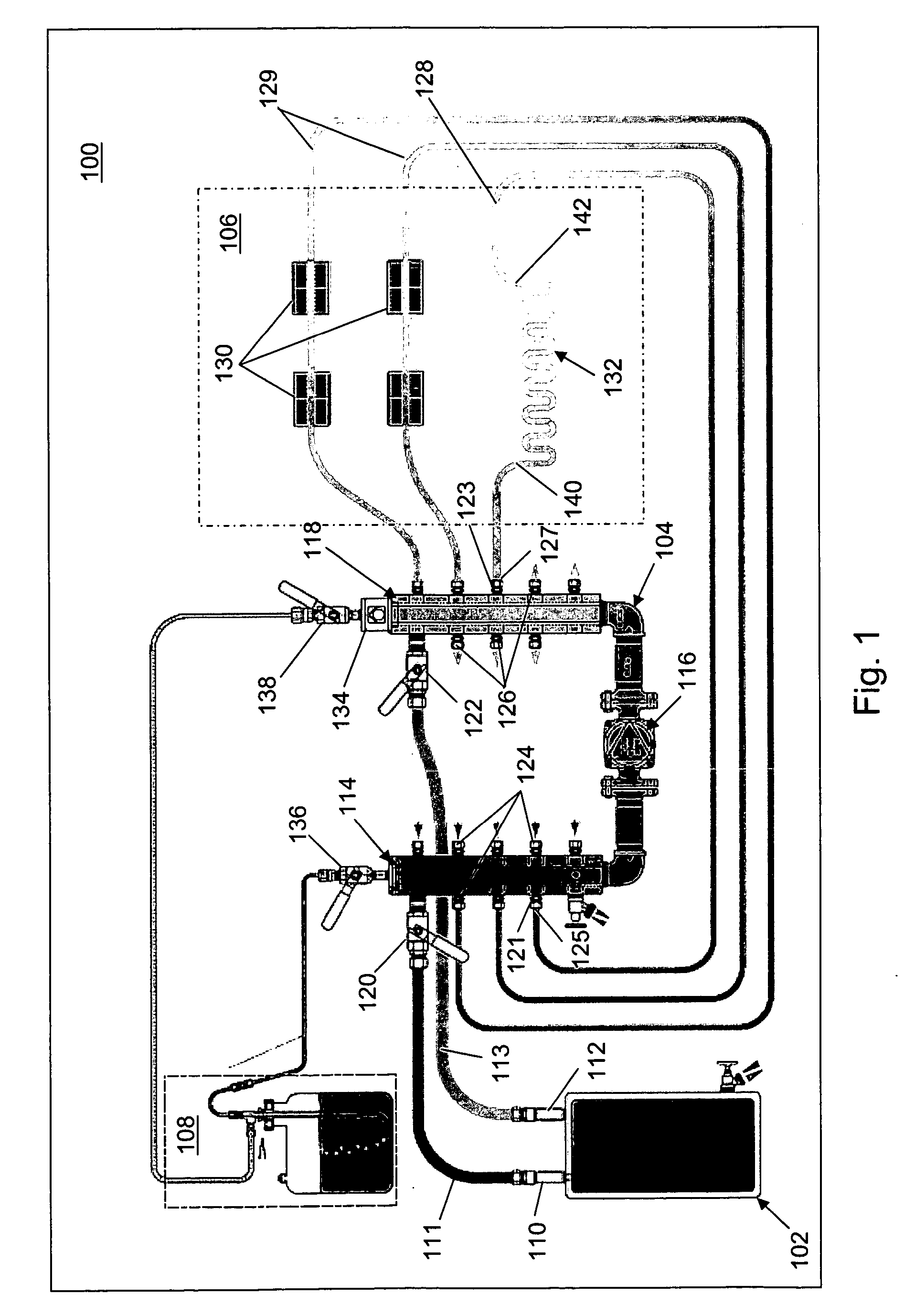

[0039] With reference to FIG. 1, a heating system 100 is shown in an exemplary embodiment. Heating system 100 may be installed in any type of structure to provide heating or cooling thereof. Heating system 100 may include a heat transfer device 102, a circulating system 104, a heat distribution system 106, and a vent assembly 108. Heating system 100 may include a fewer or a greater number of components than shown in the exemplary embodiment of FIG. 1. Heat transfer device 102 may include an outlet valve 110 and an inlet valve 112. Outlet valve 110 supplies a heat transfer medium to heat distribution system 106 through a first pipe 111 that couples to a first inlet valve 120 of a first manifold 114. Inlet valve 112 receives the heat transfer medium from heat distribution system 106 through a second pipe 113 that couples to a first outlet valve 122 of a second manifold 118. First pipe 111 and second pipe 113 may be formed of plastic, of metal, or of a combination of materials. First p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com