Point-of-use mixing method with standard deviation homogeneity monitoring

a technology of homogeneity monitoring and point-of-use mixing, applied in the direction of controlling the mixing ratio of fluids with different temperatures, process and machine control, instruments, etc., can solve the problems of unsatisfactory delays, waste of chemistry resources, and inability to meet the requirements of the test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

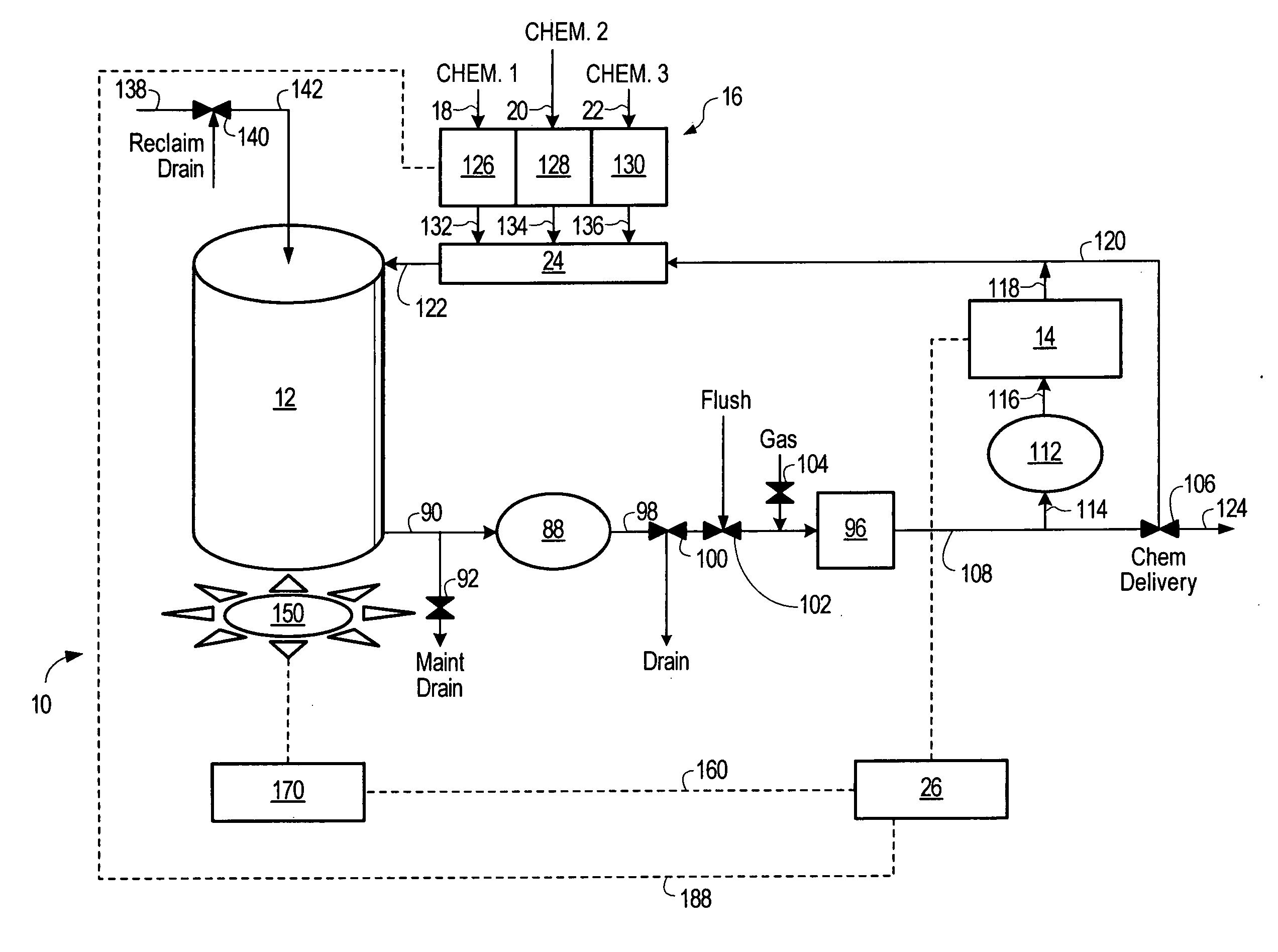

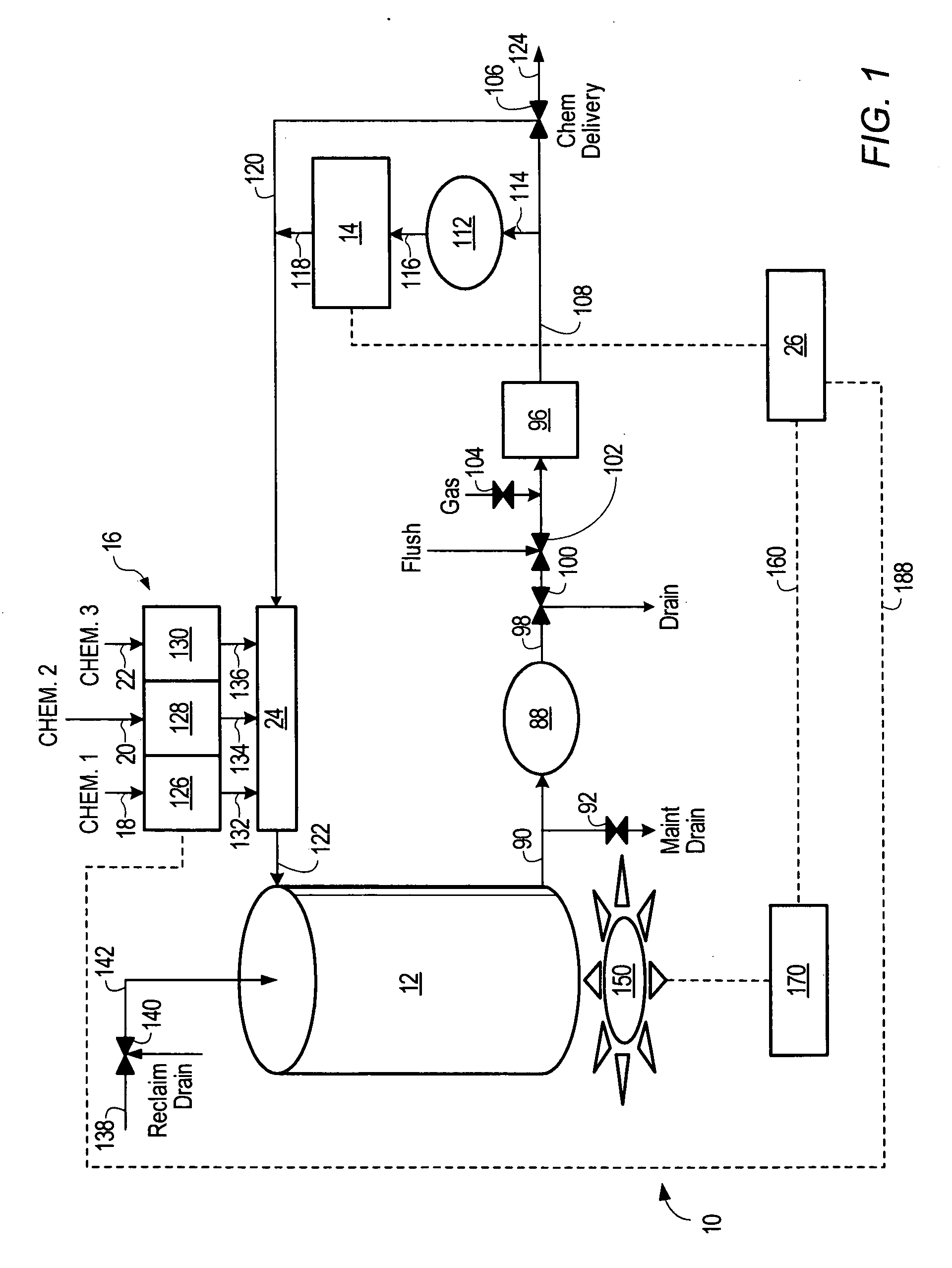

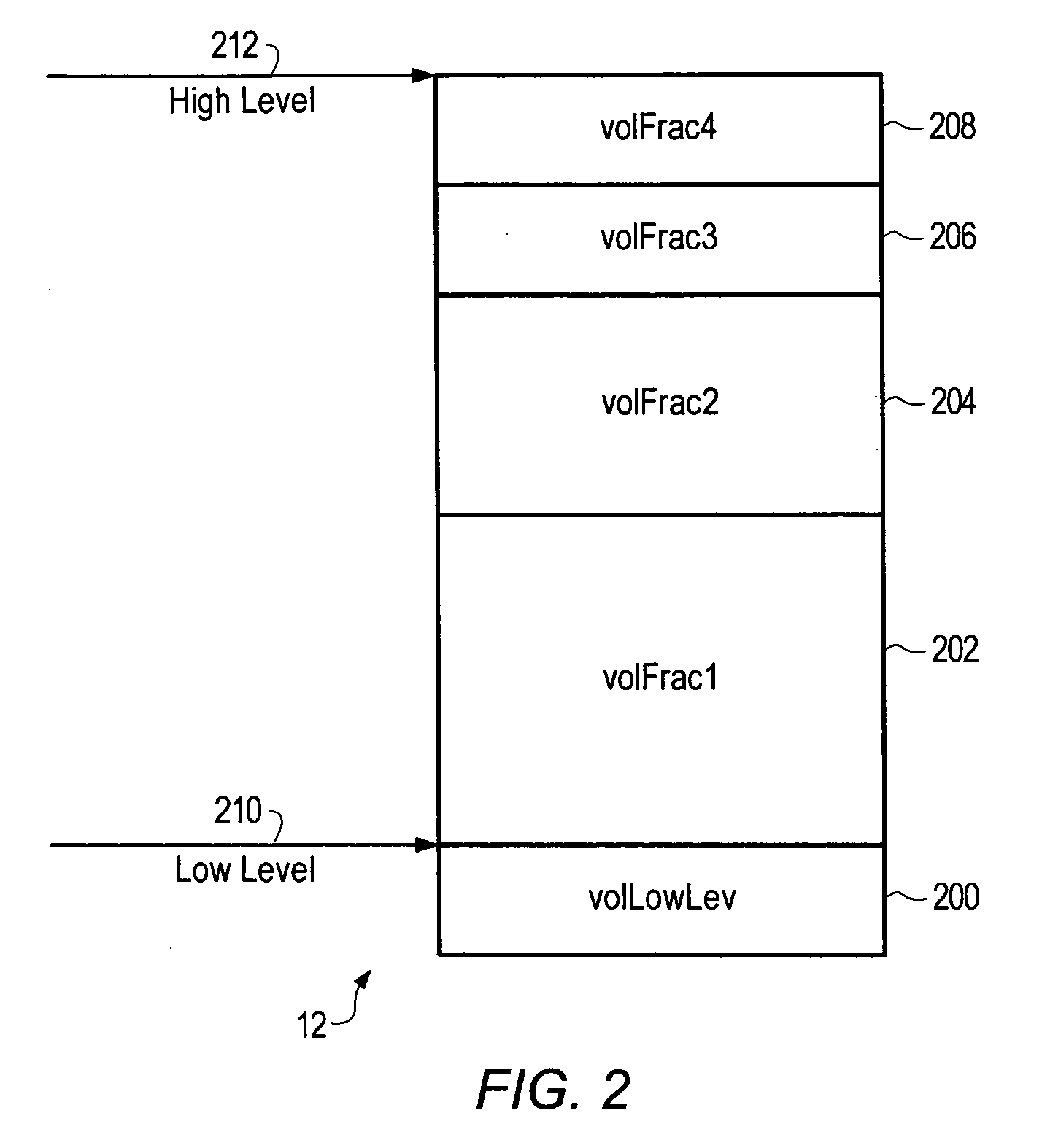

[0030] According to certain embodiments, there is provided a system and method of formulating a composition comprising at least two chemicals. Chemicals that may be used include, but are not limited to acids (e.g., inorganic acids, mineral acids, and organic acids), bases (e.g., inorganic bases and organic bases), and carrier fluids (e.g., water, alcohols, etc.). Chemicals that may be mixed include solids, liquids, gases and combinations thereof. Generally, the chemicals are dispensed into a container to partially fill it. The quantities of the chemicals in the container are determined, and a ratio of a target quantity to the determined current quantity for at least one chemical is calculated. As used herein the “quantity” of a chemical refers to any of the following measurements of the chemical: weight, volume, weight percent, volume percent and concentration. The next quantity of that chemical to be admitted to the admixture is calculated by multiplying the target quantity by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com