Button actuated mechanism for a dispensing canister

a technology of actuating mechanism and aerosol product, which is applied in the directions of liquid dispensing, packaging, transportation and packaging, etc., can solve the problems of difficult assembly and difficult mold assembly, and achieve the effect of simple functionality and economics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

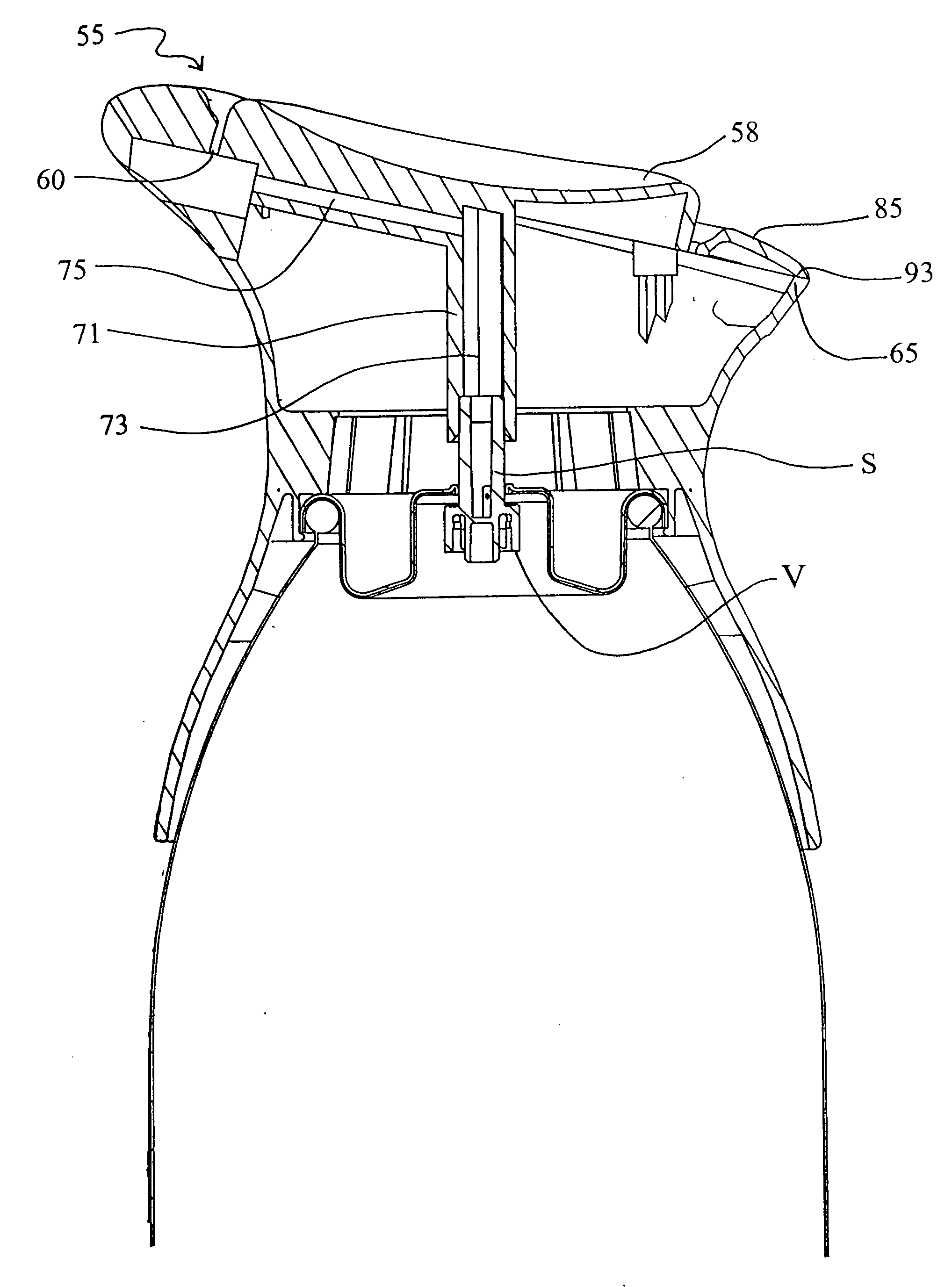

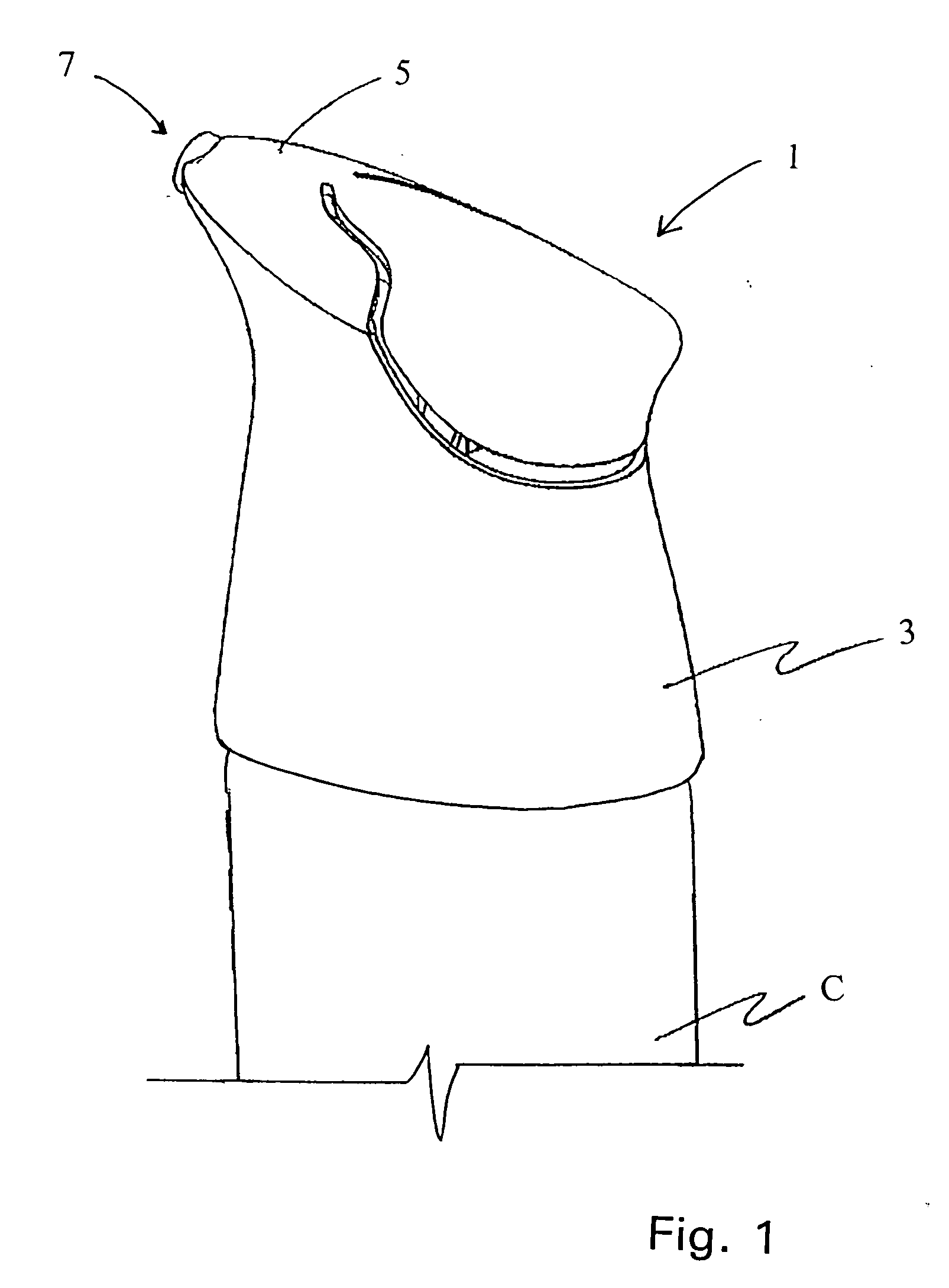

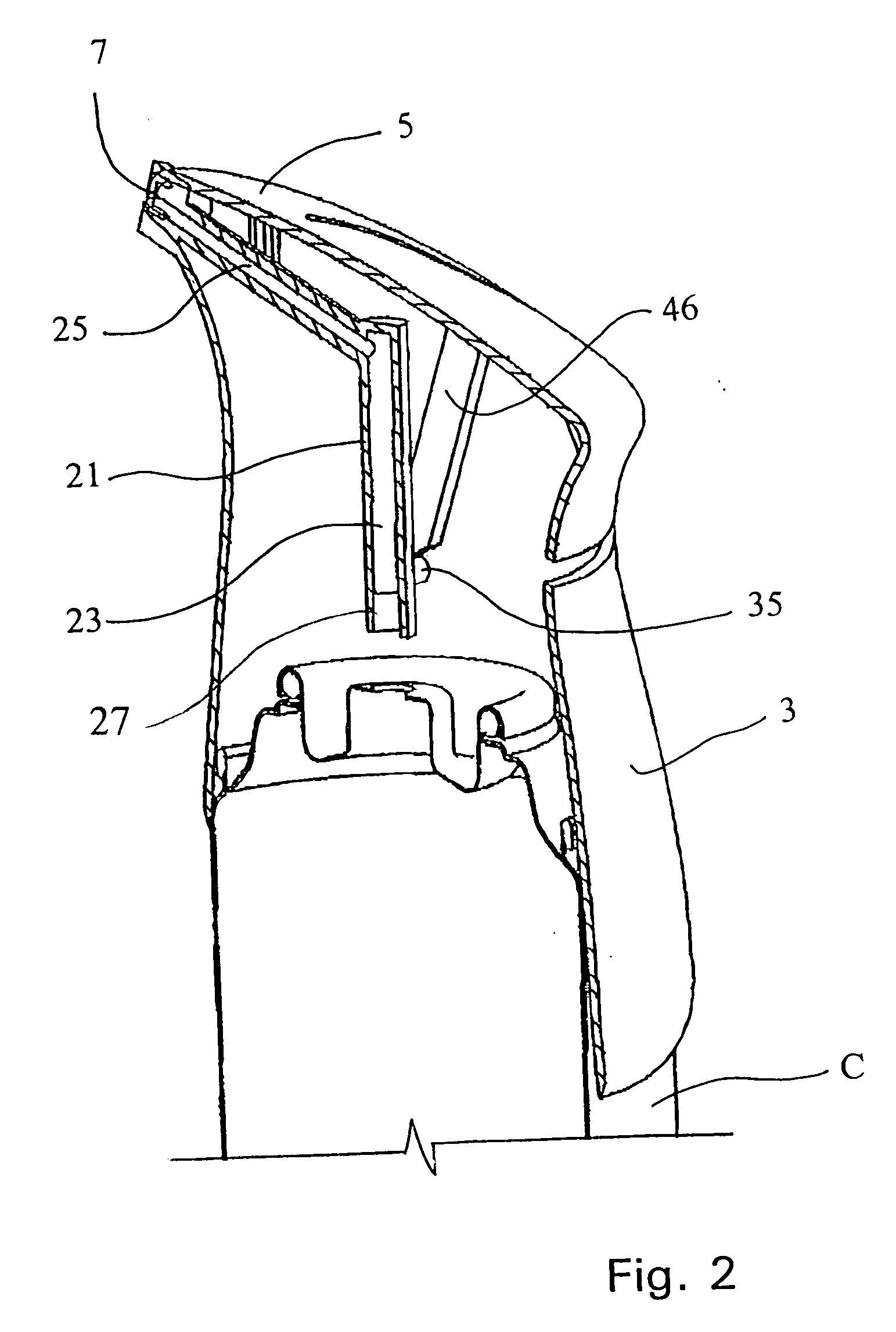

[0041] An embodiment of the present invention is shown in FIGS. 1 to 7 as an aerosol spray actuator mechanism 1 for use in conjunction with a pressurized aerosol spray can C. The actuator mechanism 1 is comprised of three separately molded elements, a main body 3, a button cap 5, and a nozzle 7 as described in further detail below.

[0042] The main body 3 shown separately in FIGS. 4A-B and 5, is a hollow, substantially cylindrical, or conical shell having a sidewall 8 which slightly tapers from a bottom end 9 for engaging the aerosol can C to a top end 11 for supporting the button cap 5. The sidewall 8 is defined about a longitudinal axis A passing through the approximate center of the actuator 1 and the valve stem of the pressurized canister. The taper may include a waist portion 10 which has a smaller diameter than the remainder of the main body 3 relative to the axis A to provide ergonomic grasping of the actuator 1.

[0043] As seen in FIGS. 4A, 4B and 5, the top edge 15 of the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com