Connector for concrete panels

a technology of connecting rods and concrete, which is applied in the direction of building reinforcements, constructions, building components, etc., can solve the problems of difficult to obtain the degree of accuracy or the desired holding power using these devices, the structure is not entirely satisfactory, and the wings are not well retained, so as to reduce the cost of assembly, simple and inexpensive manufacturing, and the effect of reducing the cost of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] When referring to the preferred embodiment, certain terminology will be utilized for the sake of clarity. Use of such terminology is intended to encompass not only the described embodiment, but also technical equivalents, which operate and function in substantially the same way to bring about the same result.

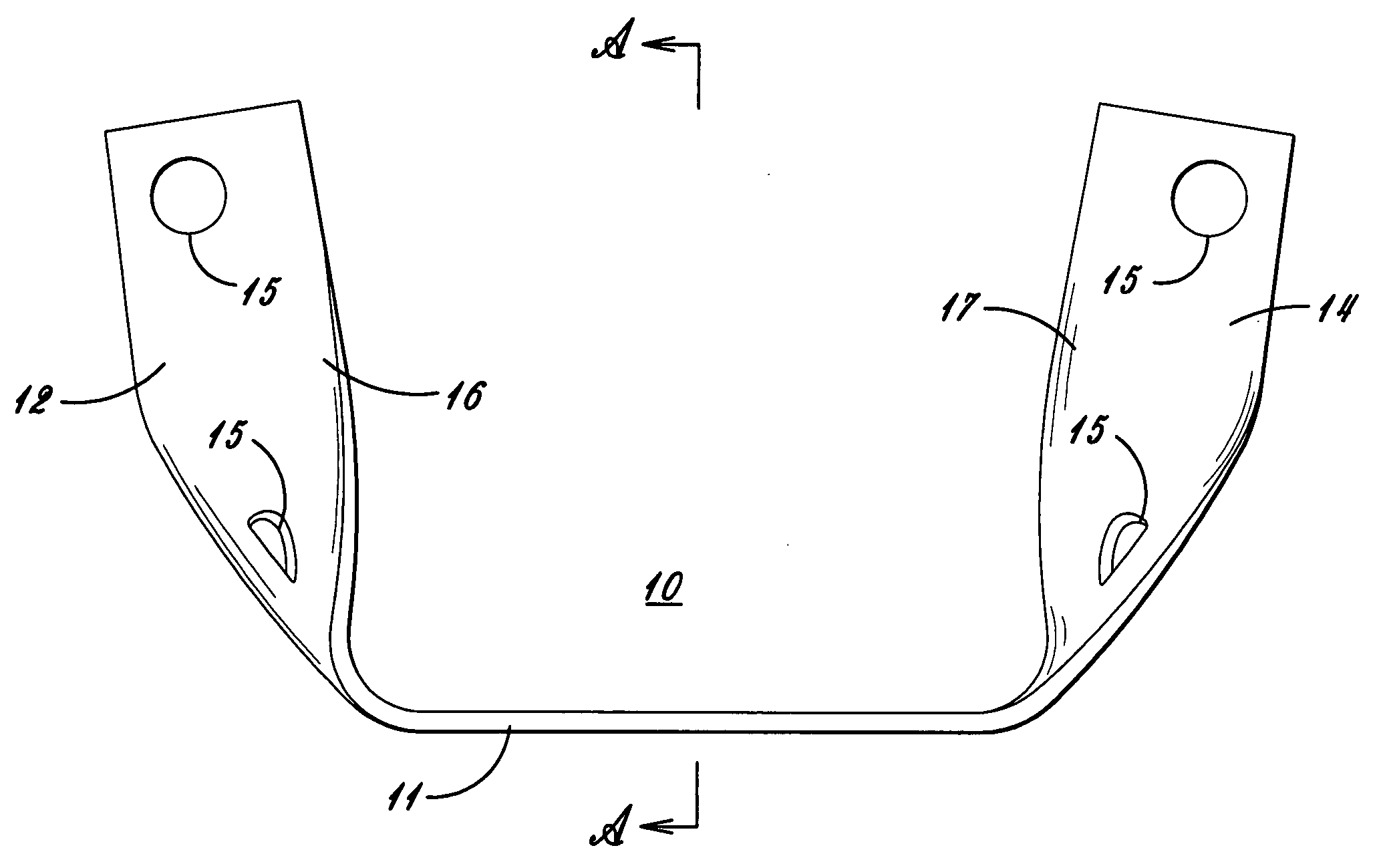

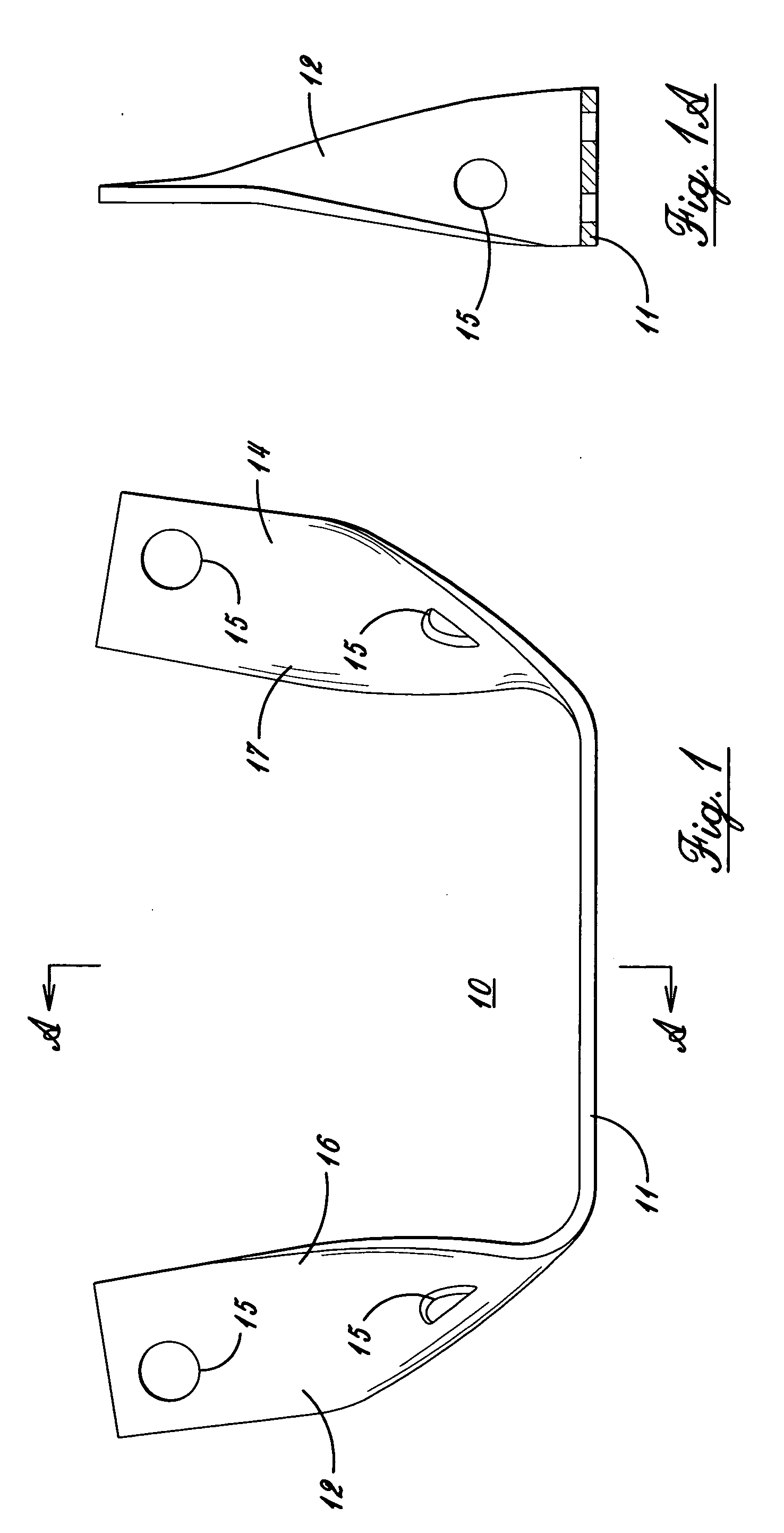

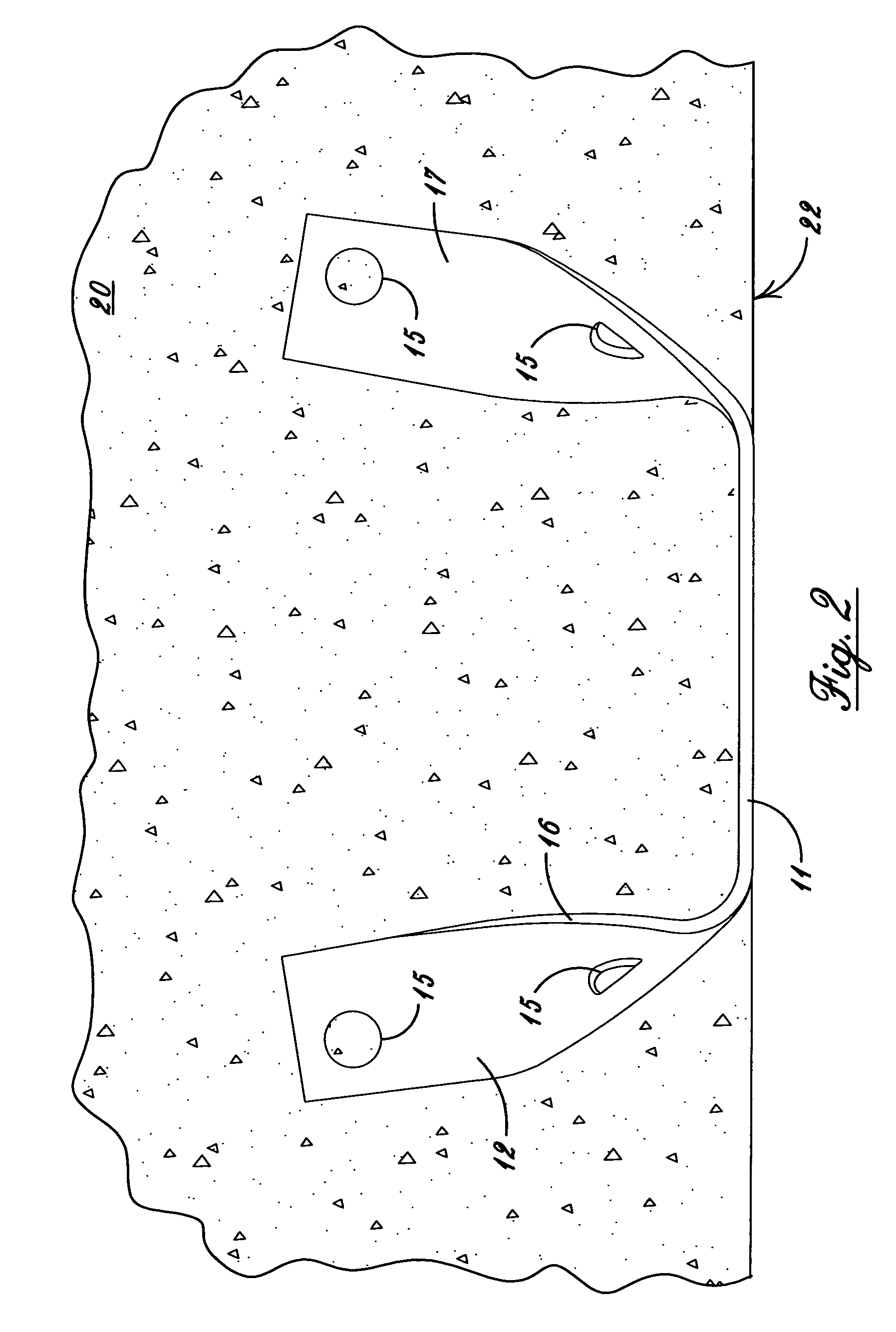

[0024] Preferring now more particularly to the drawings and FIGS. 1-4 thereof the connector 10 of the invention is therein illustrated. The connector 10 is of U shape, and includes a center flange 11 and two side flanges 12 and 14. The connector 10 is preferably formed by bending a flat strip of metal, preferably stainless steel, of two inch width, and one quarter inch thickness with an initial length of twenty inches. The side flanges are bent to an angle of 90°, six inches from the end of the strip, and the ends of the flanges are twisted at an angle of 90°; providing curved surfaces 16 and 17.

[0025] The side flanges 12 and 14 can be provided with two or more holes 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com