Tool for removing dents from sheet metal

a technology for removing dents and sheet metal, which is applied in the field of tools for pulling dents, can solve the problems of affecting the removal effect of dents, the risk of breaking or disconnection of the coupling device from the sheet metal surface, etc., and achieves the effect of easy and accurate removal of dented portions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

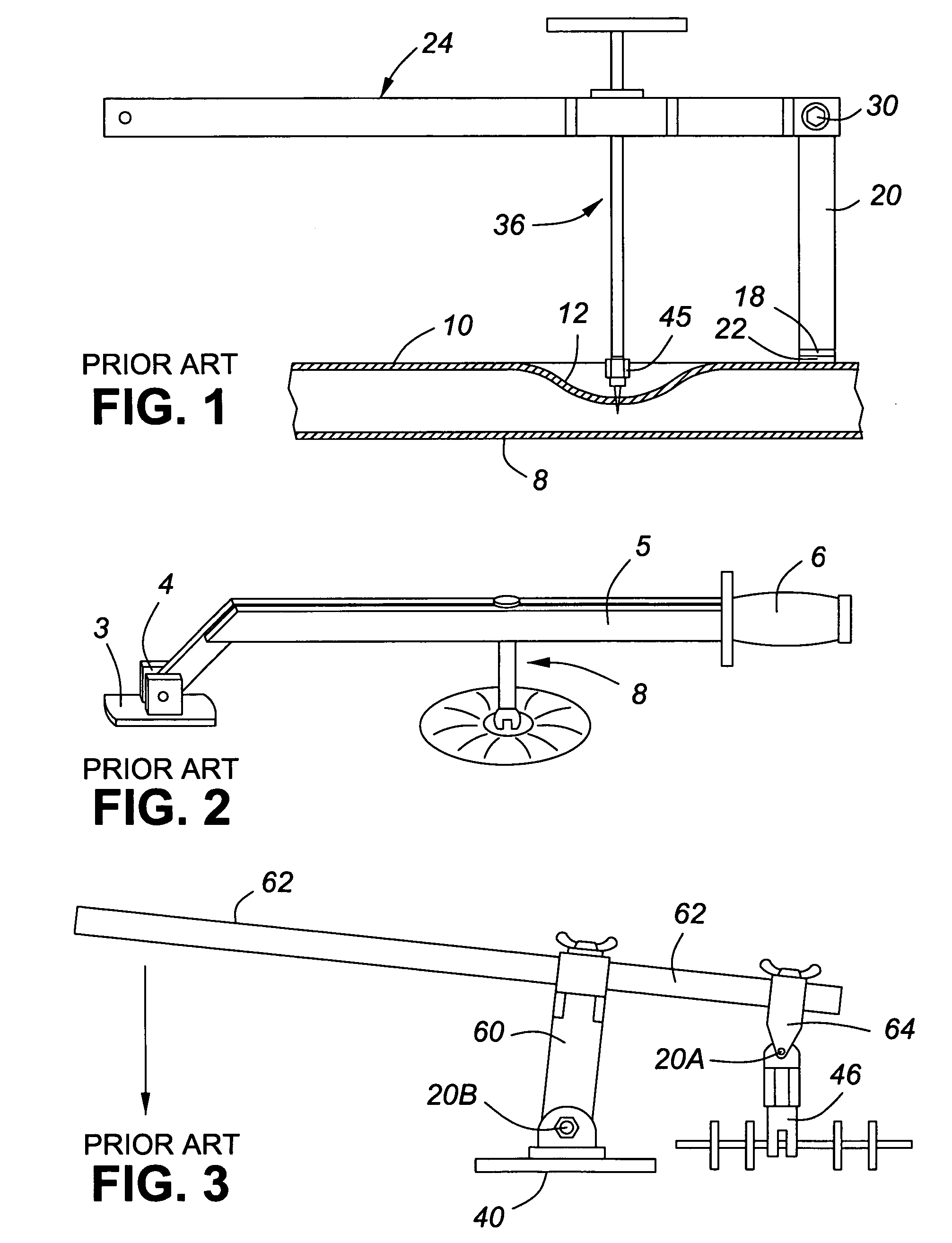

[0040]FIG. 1 shows the prior art metal panel repair tool U.S. Pat. No. 2,749,795, dated Jun. 12, 1956 issued to Boykin, Jr. This device provides a support post 20 with a base 18 shaped to rest against an adjacent portion of an outer body panel 10 overlying an inner body panel 8 on a vehicle. To this post 20 is connected a hinged lever arm 24 with an extending handle portion which, in turn, carries a connecting or pulling rod 36 for coupling to the dented portion 12 of the surface 10 which is to be drawn-out. This mechanism acts as a second lever.

[0041] The pulling rod 36 is fastened to a sheet metal screw 45 which engages with the inwardly-dented sheet metal surface 10. The lever arm 24 and support post 20 are depicted as being at 90° to each other at the commencement of the pulling process. In this configuration the pulling rod 36 is parallel to the upright support post 20 which extends vertically from the auto body surface 10. No provision is made for the pulling rod 36 to swivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| of rotation | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com