Rigid-flexible printed circuit board for package on package and manufacturing method

a printed circuit board and rigid-flexible technology, applied in the direction of printed circuit manufacturing, printed circuit aspects, semiconductor/solid-state device details, etc., can solve the problems of function errors, semiconductor chips can be easily damaged, and the semiconductor chip itself cannot transfer or receive an electrical signal with electricity supplied from outside, so as to reduce the thickness of the whole package and reduce the warpage of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the invention will be described in more detail with reference to the accompanying drawings. In the description with reference to the accompanying drawings, those components are rendered the same reference number that are the same or are in correspondence regardless of the figure number, and redundant explanations are omitted.

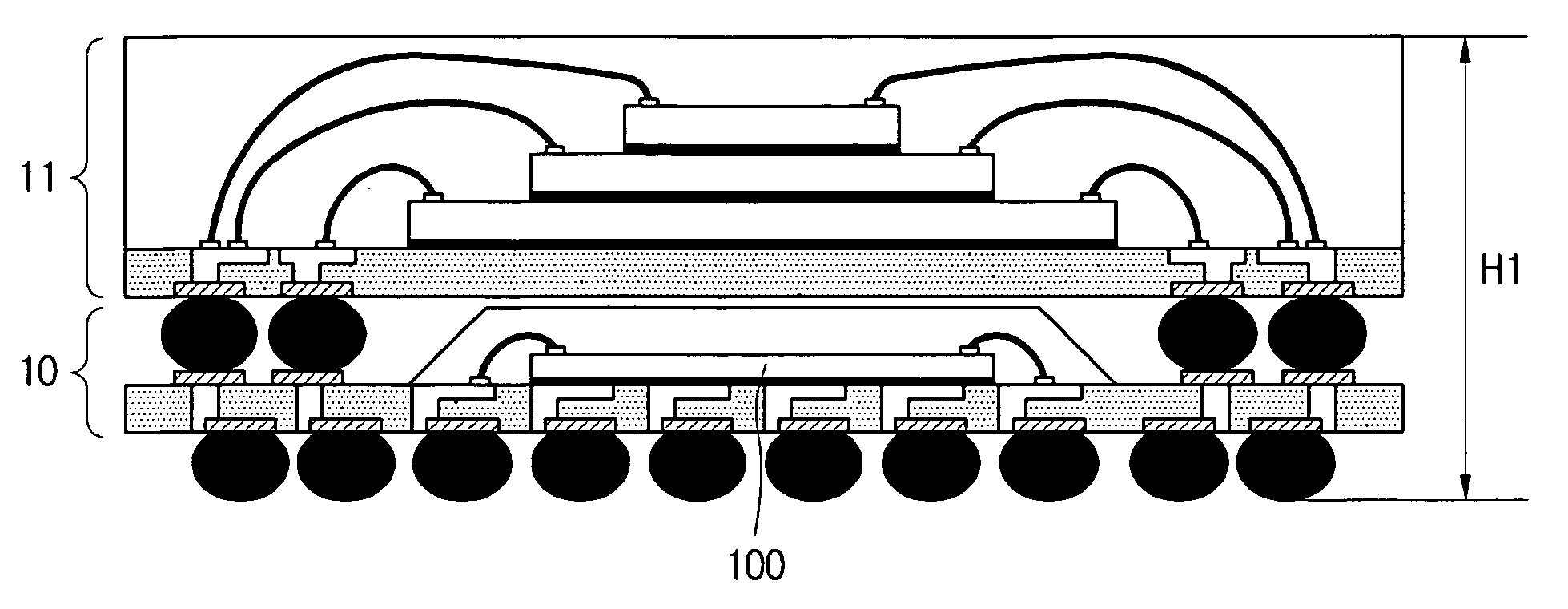

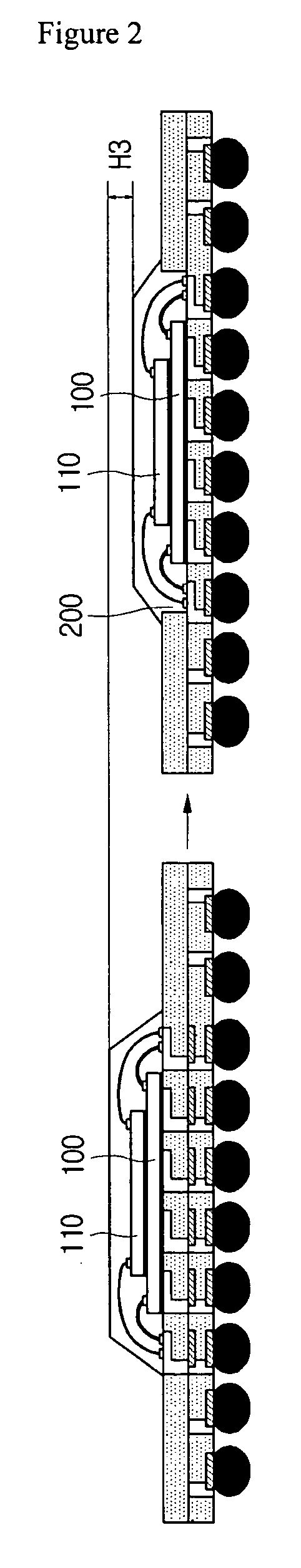

[0044]FIG. 2 shows a thinner package according to an embodiment of the present invention, in comparison with the conventional invention. A bottom substrate of a POP package is shown in FIG. 2.

[0045] Referring to FIG. 2, a package on the left side is a stack package on which 2 or more semiconductor chips 100 and 110 are mounted according to a conventional technology. A package on the right side has a cavity 200 according to an embodiment of the present invention and the semiconductor chips 100 and 110 are mounted therein so that a whole thickness of the POP package is reduced to H3. Therefore, the whole thickness of a POP pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com