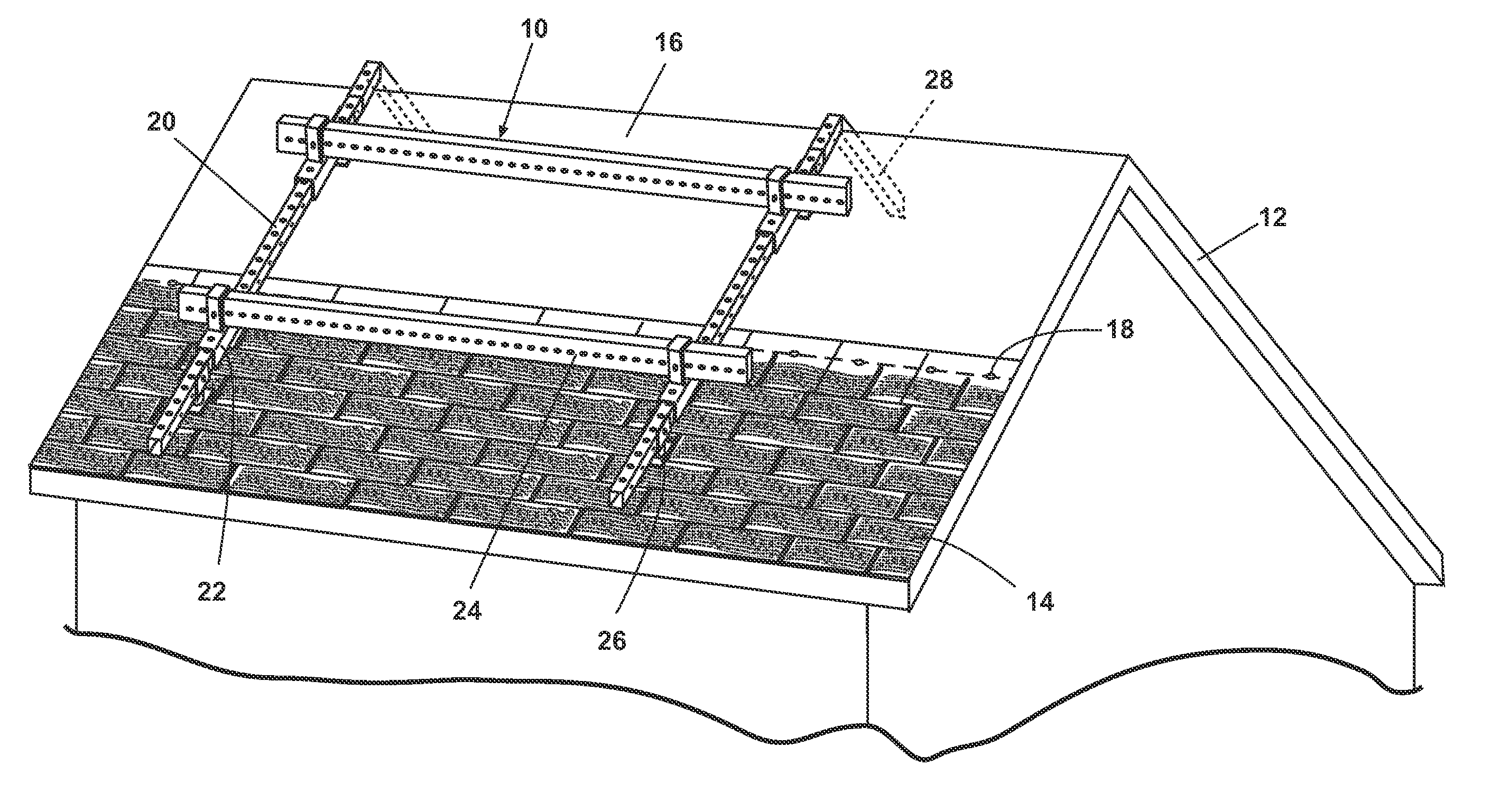

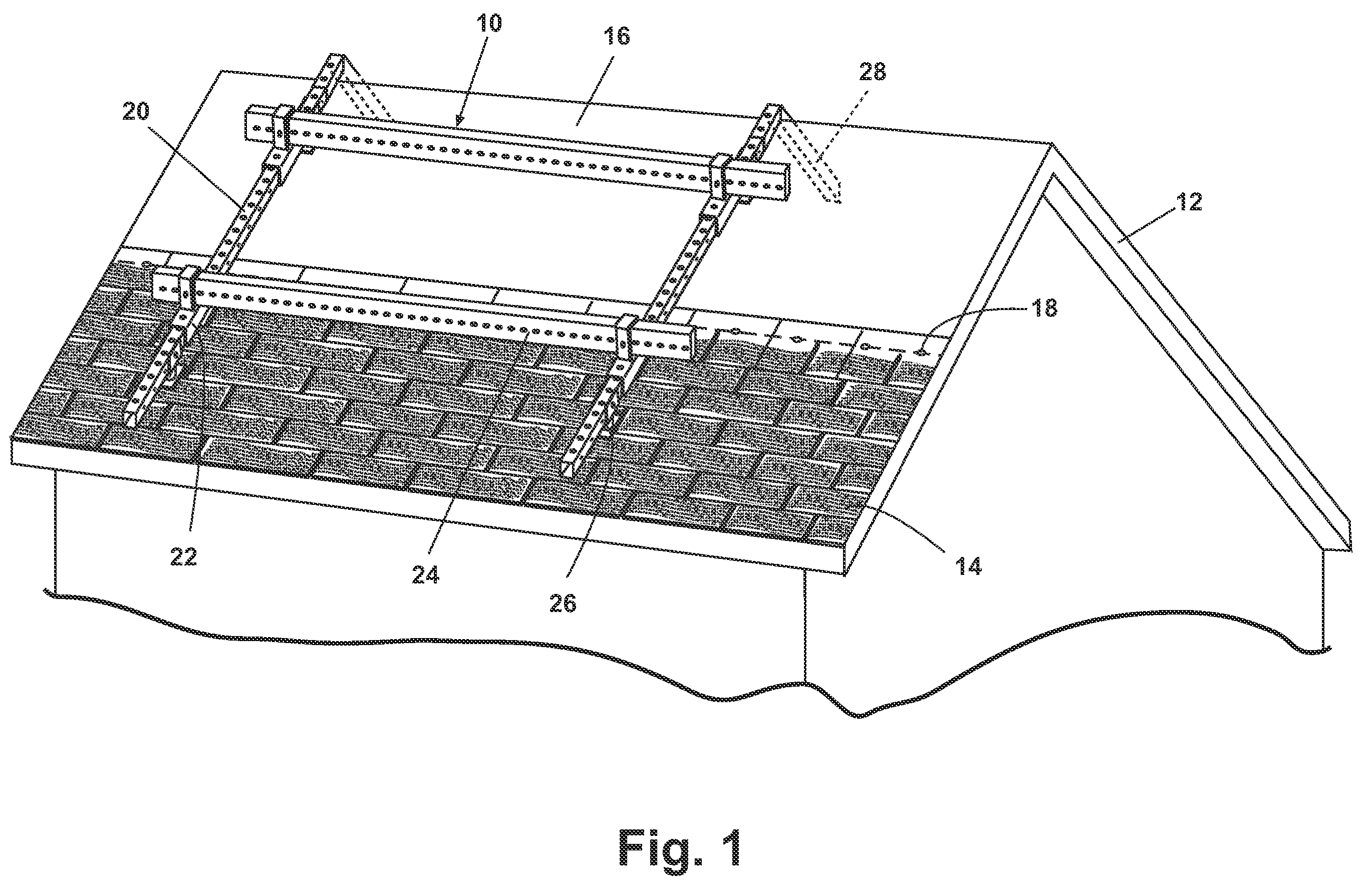

Modular roof installation scaffolding system

a scaffolding system and module technology, applied in the field of modular scaffolding systems, can solve problems such as excessive bowing or breakage, system undesirable, and unnecessary support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

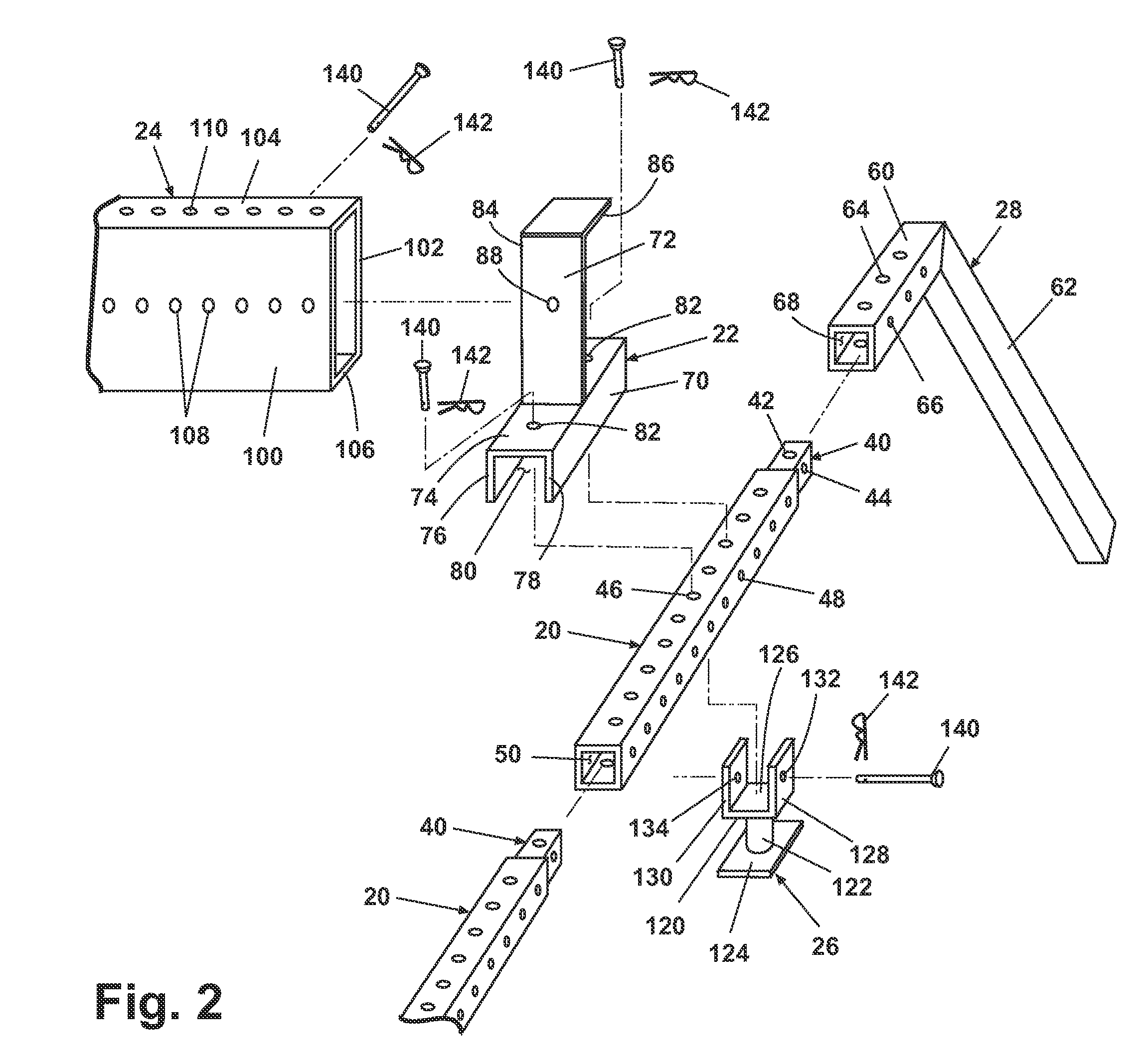

[0036] A plurality of rails 20 can be spaced along the roof 12 in order to provide a scaffolding system that extends over the entire roof area. One means of assembling the rails 20 and planks 24 into a unified scaffolding system is illustrated in FIG. 6. In this configuration, a pair of rails 20 is placed in contact along their entire length and secured together with the jack 150 adapted for slidable registry with both rails 20. The jack 150 is similar to the jack 22 except that the jack 150 is approximately twice the width of the jack 22 to accommodate two rails 20. The jack 150 comprises a sliding portion 152 and a plank support 154 in the same general configuration as the sliding portion 70 and the plank support 72. The a sliding portion 152 comprises a top wall 156 and a pair of parallel, spaced-apart side walls 158, 160 depending therefrom to define a channelway 162. Pairs of apertures 164 extend through the top wall 156 for coaxial registry with the apertures 46 in the rails 2...

third embodiment

[0040]FIG. 10 illustrates a ridge hook 220 comprising a connecting leg 222 hingedly attached to a retaining leg 224 through a hinged connection 228. The retaining leg 224 has at least one adjustment plate 226 rigidly attached thereto having a plurality of apertures 234 extending along a circular arc having its center coaxial with the hinged connection 228. The apertures 234 of the adjustment plate 226 are adapted for coaxial registry with apertures in the side walls of the connecting leg 222 for receipt of a pin therethrough. The angle a between the retaining leg 224 and the longitudinal axis 232 of the rail 20 can be selected to correspond with the ridgeline angle defined by the pitch of the roof 12 by pivoting the retaining leg 224 relative to the connecting leg 222 and securing the retaining leg 224 to the connecting leg 222 at the proper angle a by insertion of a pin 140 through the apertures in the adjustment plate 226 and the connecting leg 222. The connecting leg 222 is simil...

fourth embodiment

[0041]FIG. 11 illustrates a ridge hook 240 comprising a connecting leg 242 hingedly attached to a retaining leg 244 through a hinged connection 248. The retaining leg 244 is rigidly attached to a retaining plate 246 adapted to contact the opposed roof deck. The underside of the retaining plate 246 is provided with a plurality of teeth 252 adapted to bite into the roof deck. Additionally, the retaining plate 246 can be provided with a plurality of apertures 254 for attachment of the retaining plate 246 to the roof deck. The connecting leg 242 is similar to the connecting legs 202, 222, and is provided with apertures 250 for attachment of the insert portion 40 to the connecting leg 242 as previously described.

[0042] As an alternative to the pins 140 and retainers 142 described herein, one or more of the rails, the jacks, the planks, and the feet can be provided with generally well-known spring- loaded pins to eliminate the need for an adequate supply of pins and the inadvertent mispla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com