Pollution control device and mat for mounting a pollution control element

a technology of pollution control and mounting mat, which is applied in the direction of machines/engines, separation processes, manufacturing tools, etc., can solve the problems of reducing the holding strength of the catalyst support, under a significant decrease in strength, etc., and achieve the effect of maintaining the holding strength of the support and not impairing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

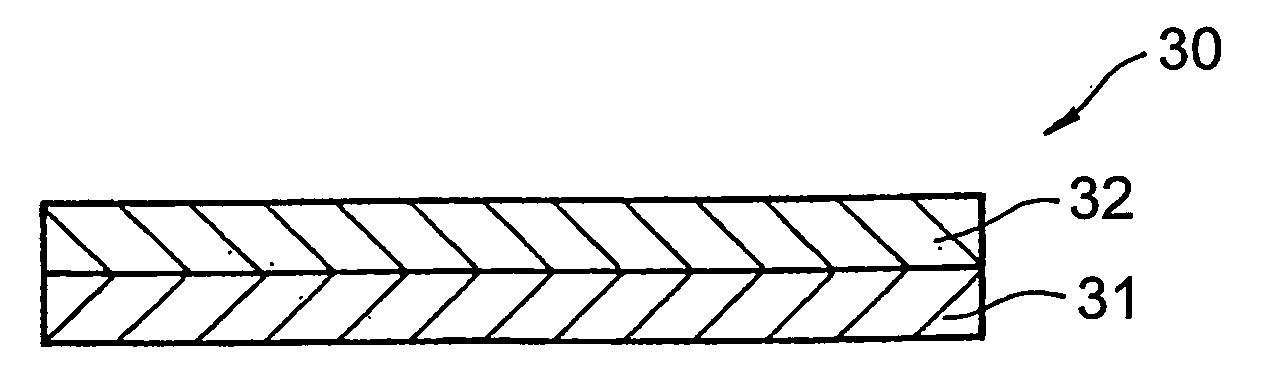

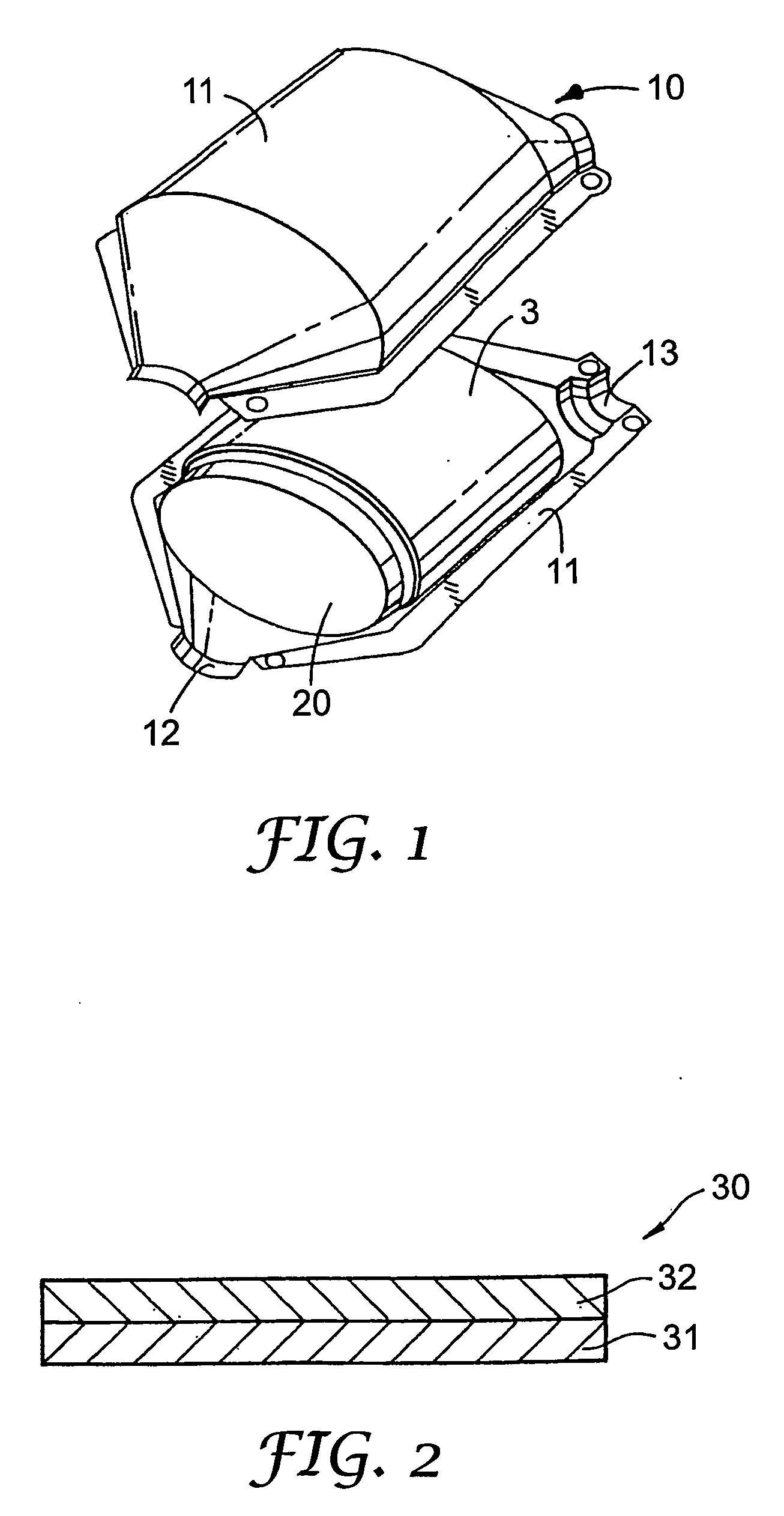

Image

Examples

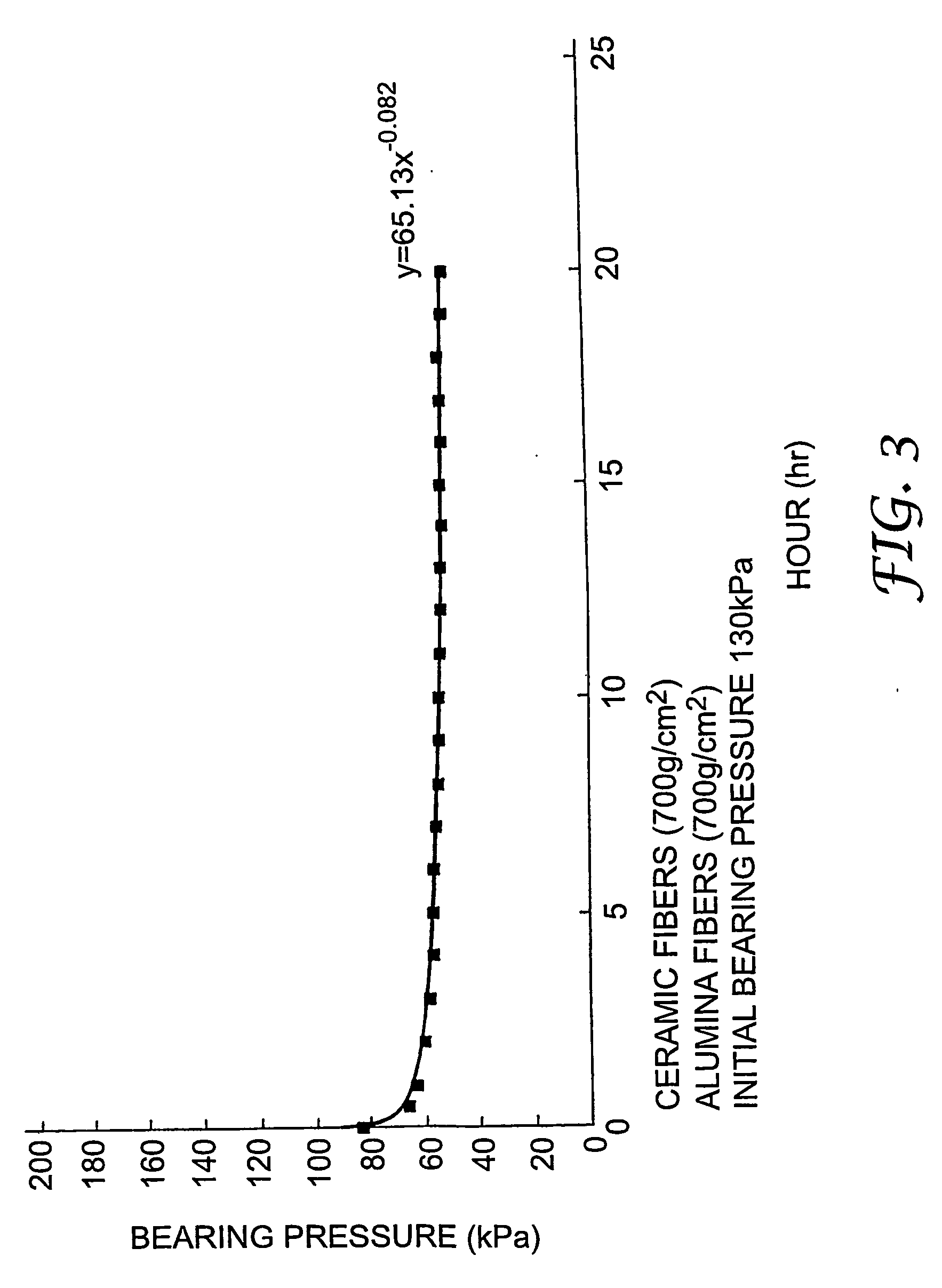

example 1

[0026] 92 wt % of alumina fibers, composed of 72 wt % of alumina and 28 wt % of silica, were mixed with 8 wt % of binder (acrylic latex, Nippon Zeon: Nippore LX-816) followed by the addition of water to prepare a first slurry. In addition, 92 wt % of silica fibers (Shinnikka Thermal Ceramics: SC-1260D1), formed by melting and composed of 46 wt % of alumina and 53 wt % of silica, were mixed with 8 wt % of the above binder followed by the addition of water to prepare a second slurry. Samples 1 through 5 of mats for mounting a catalyst support having the weighing capacity ratios between the alumina fiber layer and ceramic fiber layer shown in Table 1 were obtained by the above ordinary rolling method using these slurries.

example 2

[0027] With the exception of using ceramic fibers that were annealed for 60 minutes at a temperature of 1000° C., samples 6 through 8 of mats for mounting a catalyst support shown in Table 2 were obtained in the same manner as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com