Silent chain

a technology of silent chain and resonance, applied in the direction of driving chains, belts/chains/gearrings, chain elements, etc., can solve the problems of reducing the power transmission efficiency of the chain, noise occurrence, etc., and achieve the reduction of the chordal oscillation, and the reduction of the resonan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

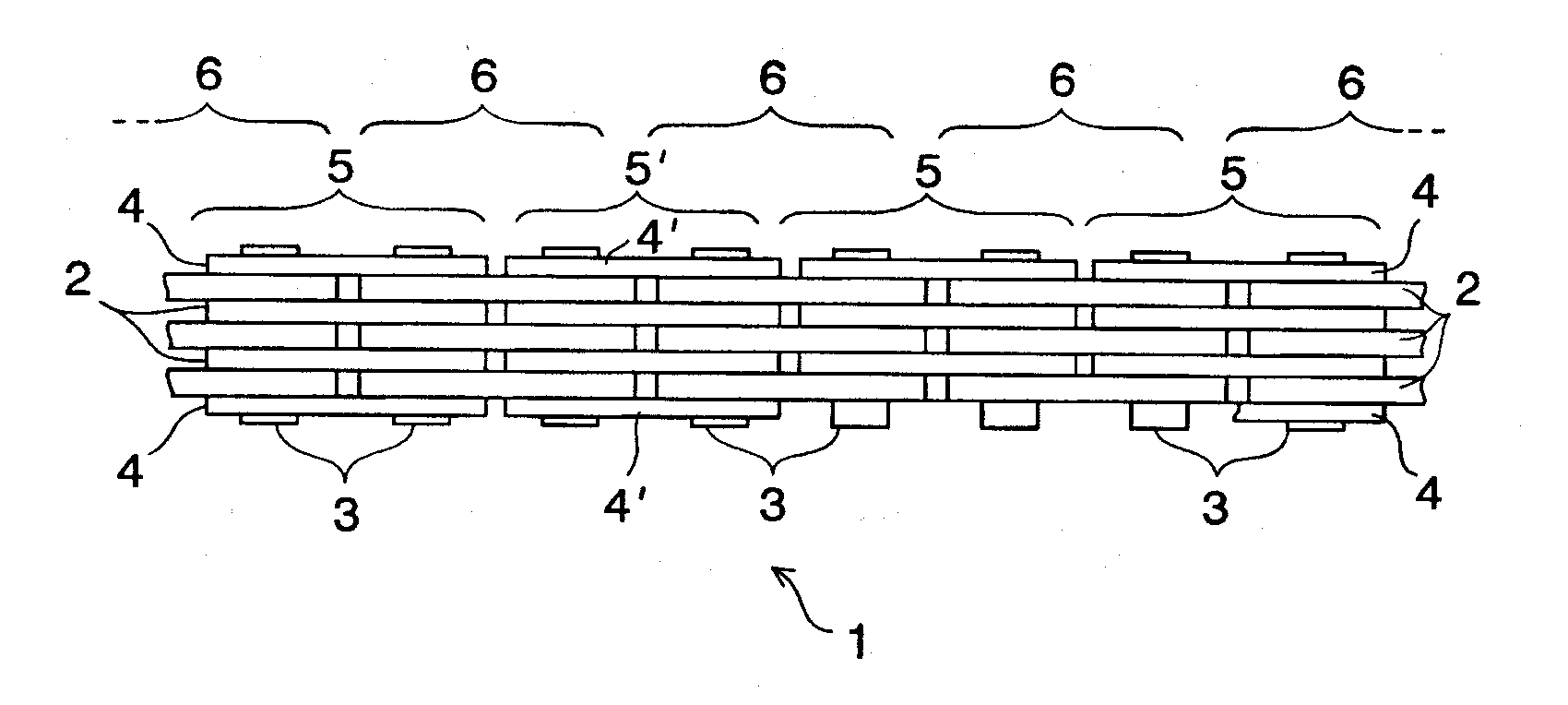

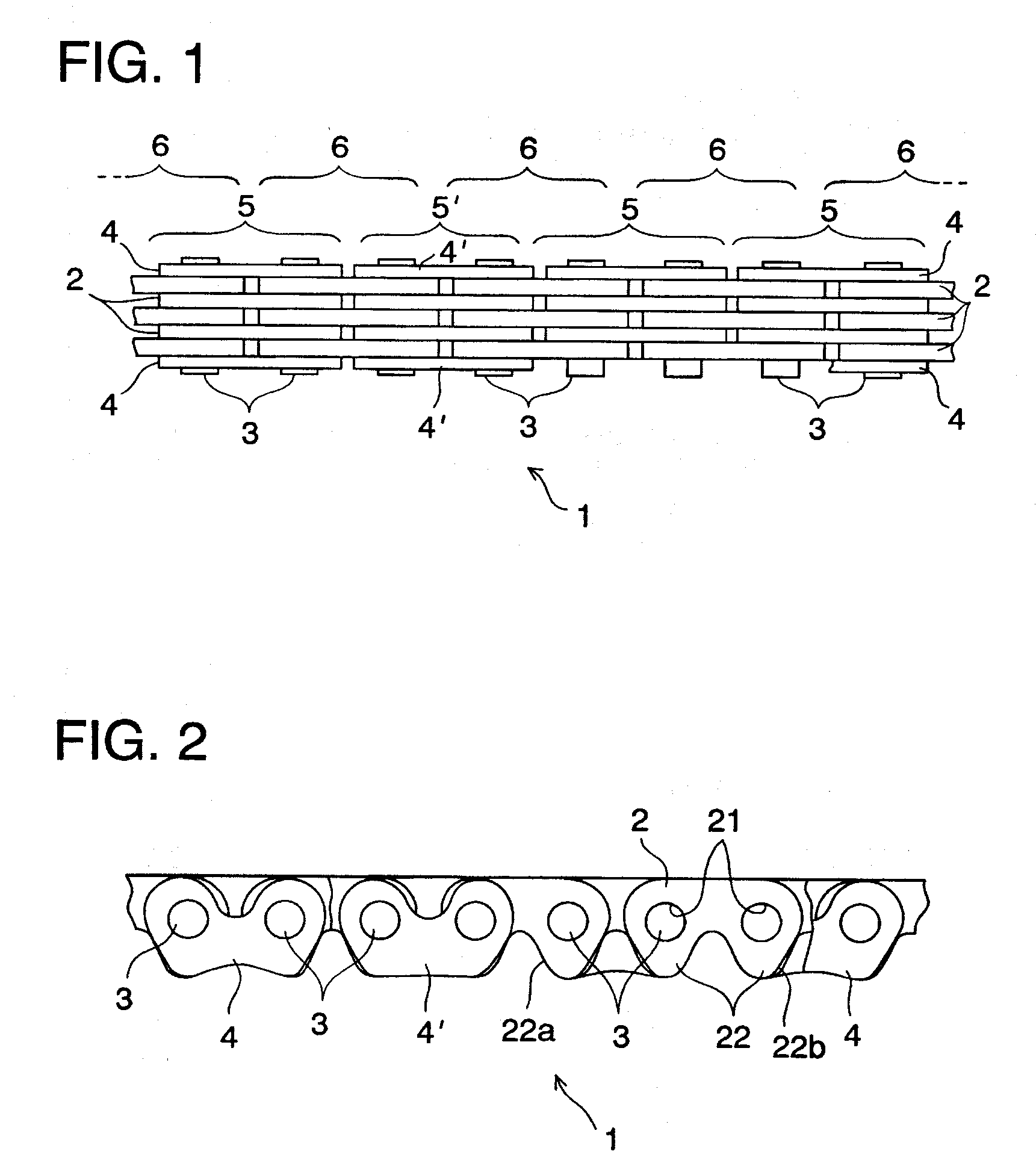

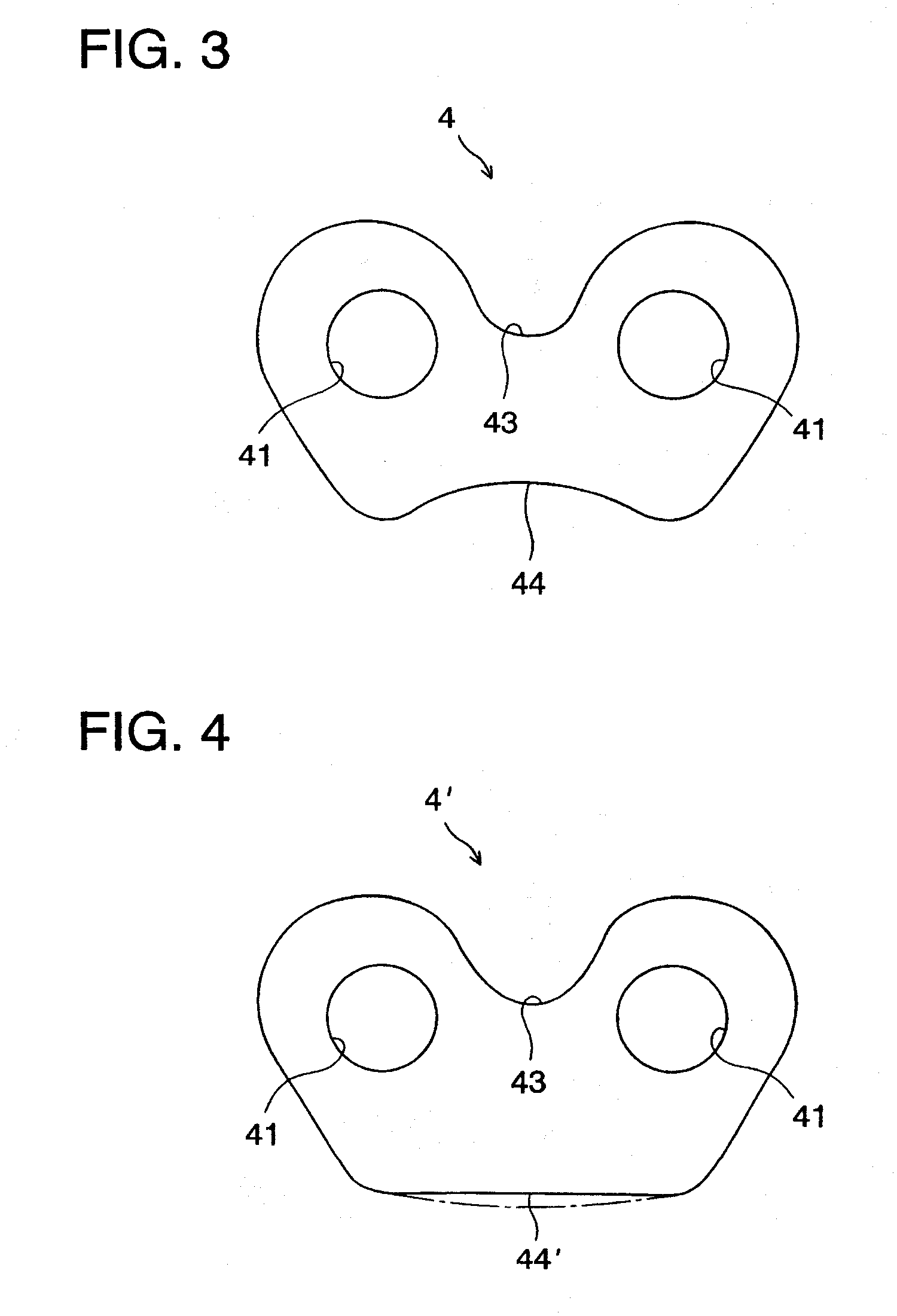

[0028] FIGS. 1 to 4 illustrate the present invention. As shown in FIGS. 1 and 2, a silent chain 1 is composed of a plurality of link plates 2 interleaved in the lateral and longitudinal directions and pivotably connected by connecting pins 3 and a plurality of first and second guide plates 4, 4′ disposed on the outermost sides of the silent chain 1.

[0029] The silent chain 1 is also composed of a plurality of guide rows 5 that are formed of the first guide plates 4 and the link plates 2 disposed at the same longitudinal position as the first guide plate 4, a plurality of guide rows 5′ that are formed of the second guide plates 4′ and the link plates 2 disposed at the same longitudinal position as the second guide plate 4′, and a plurality of link rows 6 that are formed of only the link plates 2 and that are disposed between the adjacent guide rows 5, 5′. The guide rows 5, 5′ and the link rows 6 are arranged alternately in the longitudinal direction. Also, the first and second guide p...

second embodiment

[0035]FIGS. 5 and 6 illustrate the present invention. In these drawings, like reference numbers indicate identical or functionally similar elements.

[0036] In the above-mentioned first embodiment, the weight of the guide plates varies at a random pattern in the longitudinal direction by differentiating the shapes of the backside surfaces of the guide plates, but in the second embodiment, the weight of the link rows or guide rows varies at a random pattern in the longitudinal direction by differentiating the shapes of the backside surfaces of the link plates.

[0037] The backside surface 24 of the first link plate 2 is concave in shape as shown in FIG. 5, whereas the backside surface 24′ of the second link plate 2′ is convex in shape as shown in FIG. 6.

[0038] Therefore, in this case, the link plate 24′ is heavier than the link plate 24 and the link rows or guide rows formed of these link plates 24, 24′ are arranged at a random or irregular pattern in the longitudinal direction.

[0039]...

fourth embodiment

[0043]FIGS. 7 and 8 illustrate the present invention. In these drawings, like reference numbers indicate identical or functionally similar elements.

[0044] In the fourth embodiment, washers 30 are fixedly attached to the ends of the connecting pins 3. The locations of the washers 30 are arranged at a random pattern in the longitudinal direction.

[0045] In this case as well, the weight of the chain span between the drive and driven sprockets varies successively during operation and eigenfrequency of the chain span thus varies successively. Thereby, occurrence of the resonance can be restrained and chordal oscillation of the chain span can be decreased.

[0046] In the above-mentioned first to third embodiments, two types of guide plates, link plates, or connecting pins of different weight were used, but the present invention can be applied to the case in which three type s or more of guide plates, link plates, or connecting pins of different weight are used.

[0047] In the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com