Method for weaving curved warp yarns and a woven fabric

a technology of woven fabrics and woven fabrics, which is applied in the direction of looms, textiles and papermaking, manufacturing tools, etc., can solve the problems of limited fabric color and design, and achieve the effect of overcomplicating the monotony of the current loom woven fabri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for weaving warp curve fabrics according to the present invention including the following steps:

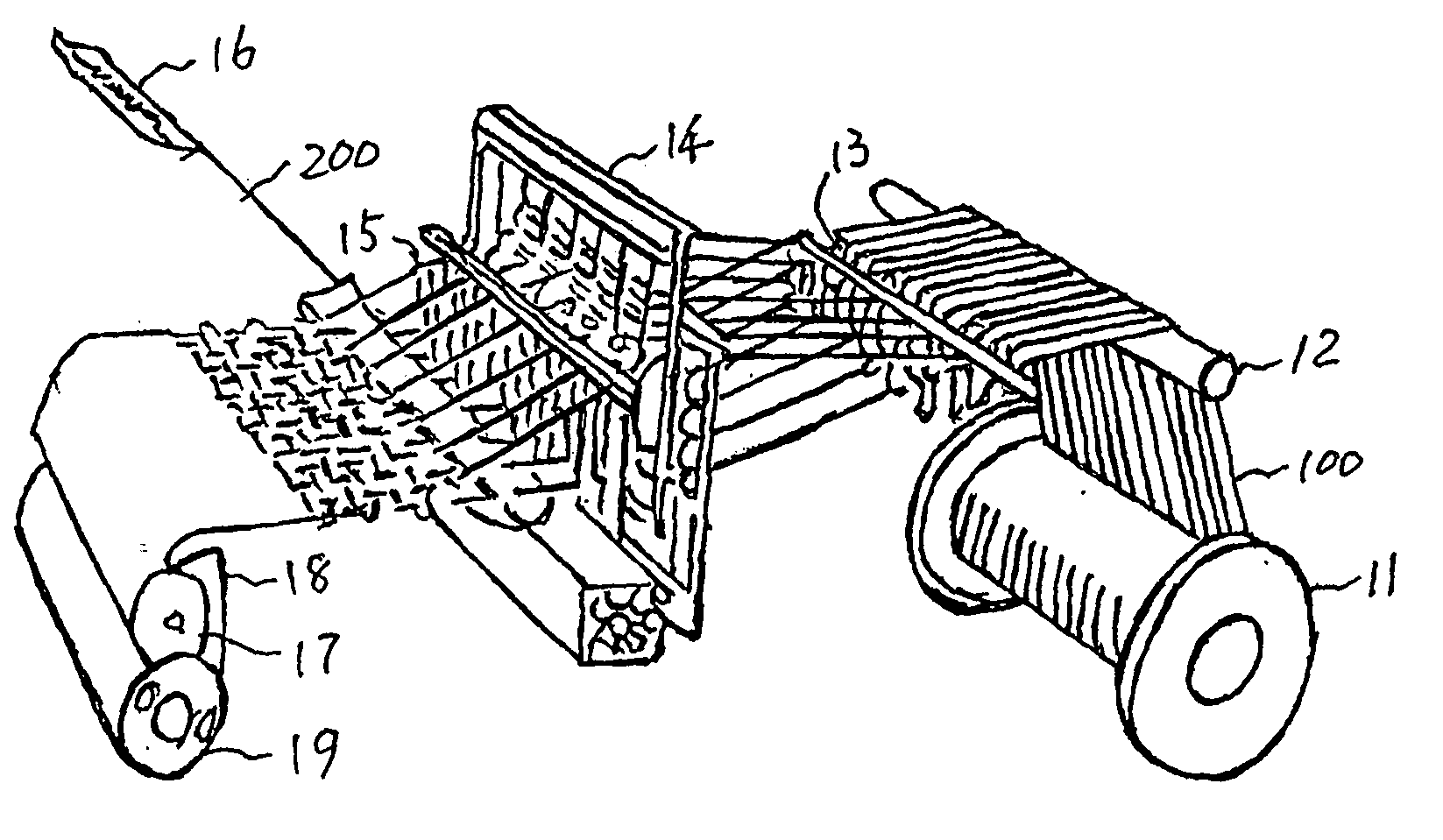

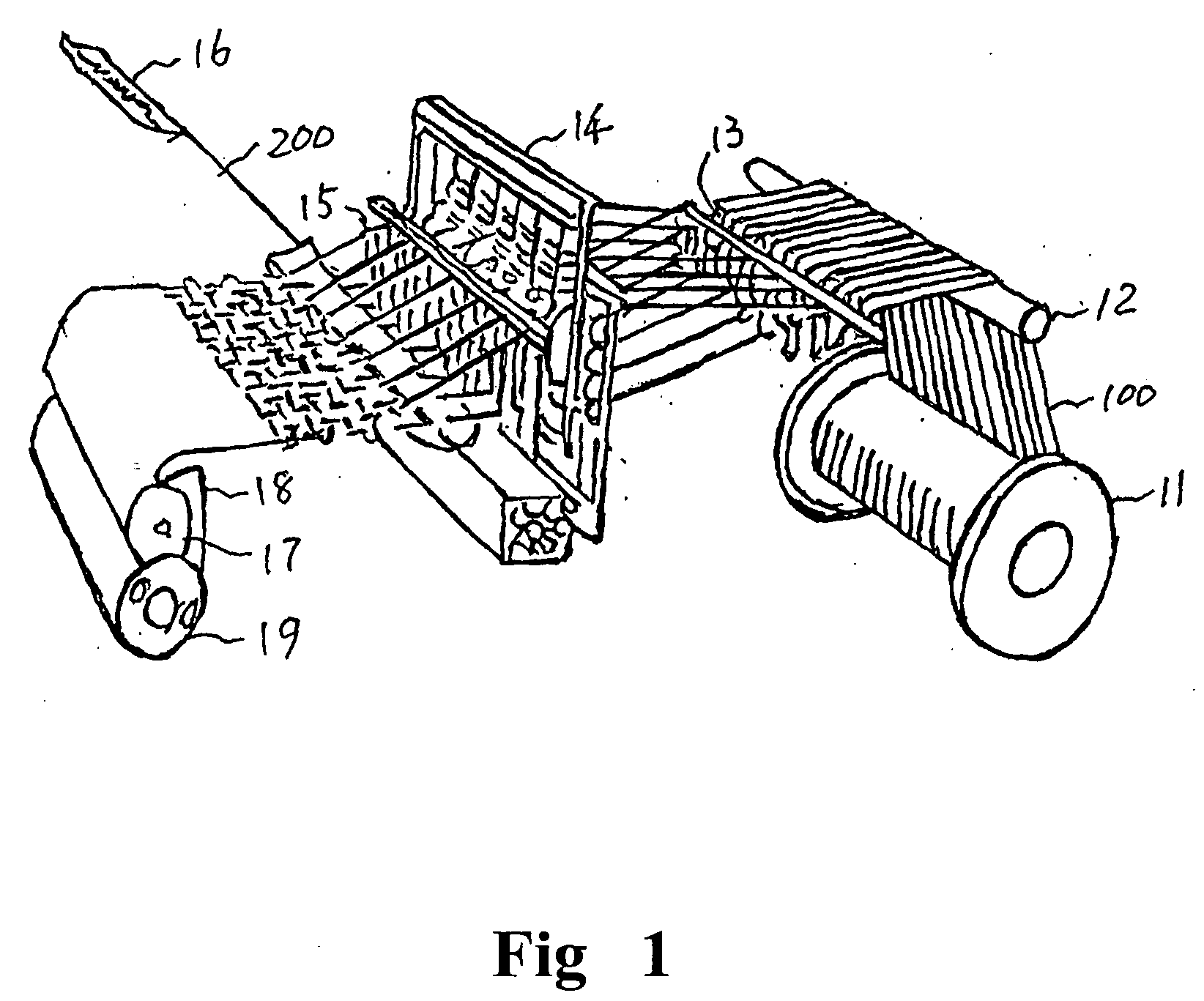

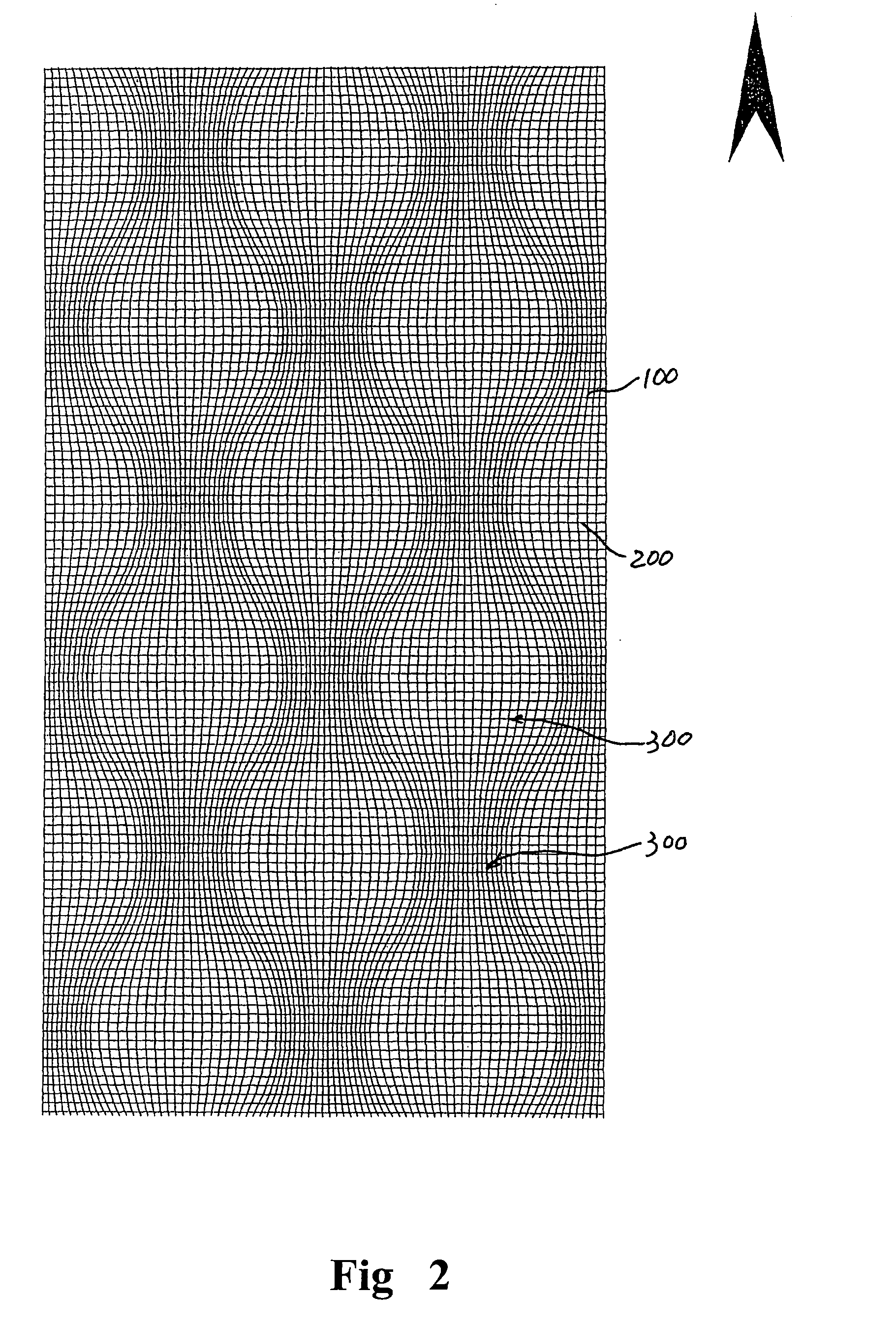

[0031] a) Straight and slant warp let-off; by means of the cooperation of the let-off unit of the weaving machine, feeding the warp into the shedding member of the weaving machine, the fed quantity of warp matches the take-up quantity required by the take-up unit. At the same time, the lifting and descending member draws the metal reed with the straight and slant dents the spacing between which is variable to make it to do up and down reciprocating movement and to make the warp restricted by slant reed blade of the reed to form slant line state with respect to the fell of cloth of fabric in which state the inclination degree varies relative to the fell of cloth. The straight-slant warp let-off and the forming of straight and slant warp is due to such process that the straight and slant dent metal reed mounted in the sliding frame on the slay is drawn by the metal reed l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| colors | aaaaa | aaaaa |

| travel distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com