Television frame and manufacturing method thereof

A TV and frame technology, applied in the field of TV, can solve the problems of not being resistant to salt spray, not being resistant to high and low temperature, monotony and obsolete, etc., and achieve the effect of improving product grade, strength and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below in conjunction with the accompanying drawings.

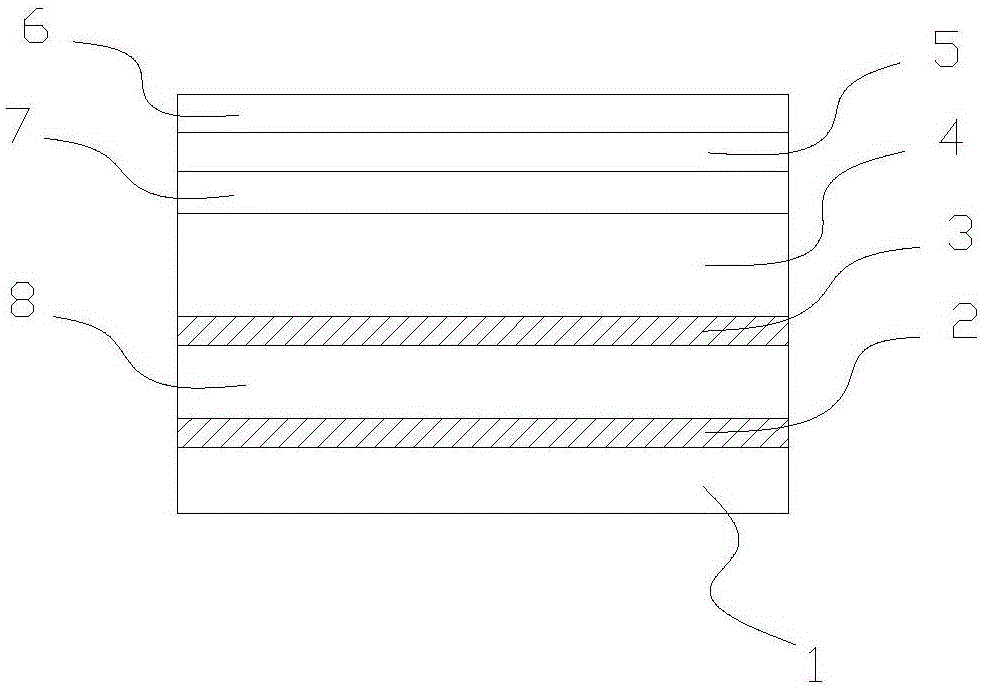

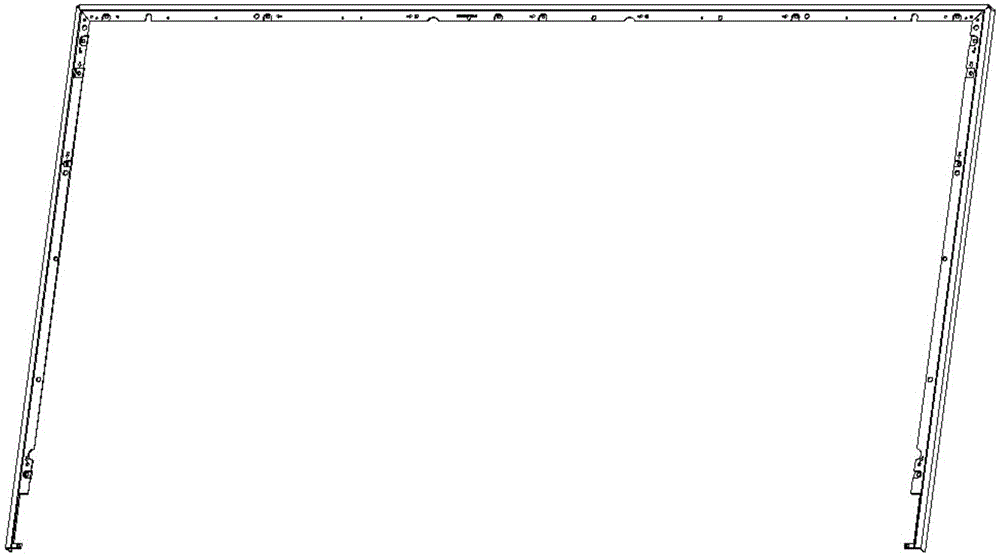

[0040] Such as figure 1 and figure 2 A TV frame is shown, which includes a Kevlar layer 1, and above the Kevlar layer 1, a glass fiber layer 8, a natural material layer 4, a primer layer 7, a middle The paint layer 5 and the topcoat layer 6, the glass fiber layer 8 is connected to the Kevlar layer 1 through the first bonding layer 2, and the natural material layer 4 is connected to the glass fiber layer 8 through the second bonding layer 3, The thickness of the Kevlar layer 1 is 0.4 mm, the thickness of the glass fiber layer 8 is 0.6 mm, the natural material layer 4 is made of wood grain, bamboo grain or other natural materials, and the first bonding Both the layer 2 and the second adhesive layer 3 have a thickness of 0.02mm, and both the first adhesive layer 2 and the second adhesive layer 3 are glue or adhesive tape.

[0041] A method for making a frame of a TV,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com