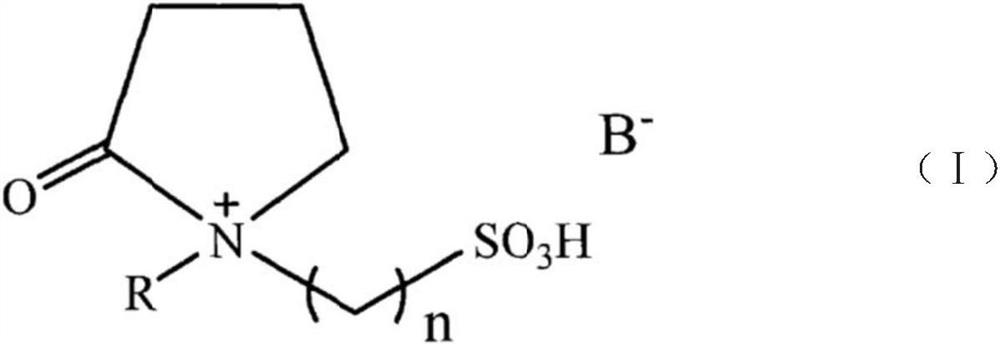

Sulfonic acid functionalized pyrrolidone ionic liquid catalyst, and preparation method and application thereof

A technology of sulfonic acid functionalization and pyrrolidone, which is applied in the direction of sulfonate preparation, organic compound preparation, physical/chemical process catalysts, etc., can solve problems such as industrial production obstacles, achieve the effect of improving conversion rate and overcoming single types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

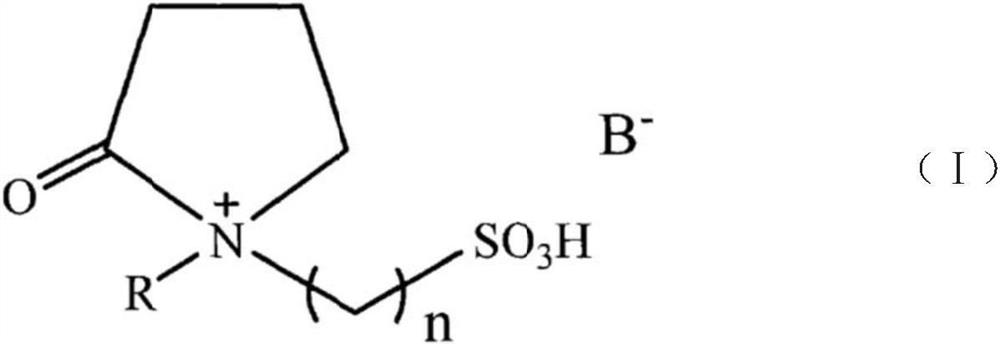

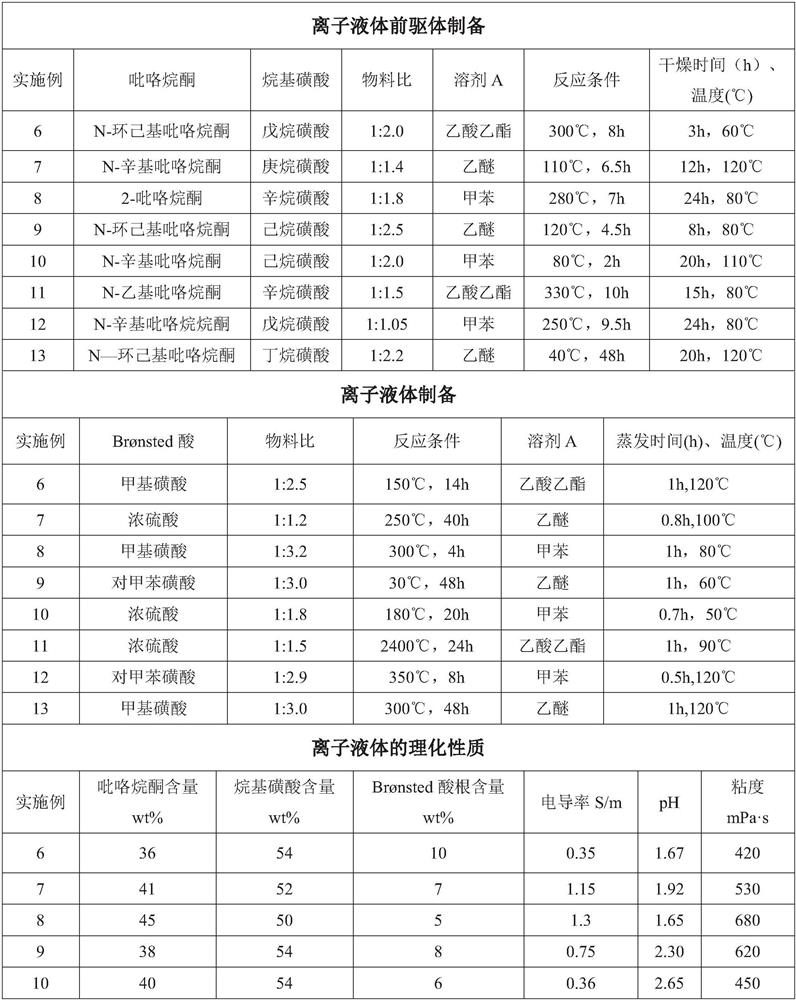

Examples

Embodiment 1

[0029] 1. Preparation of ionic liquid precursor: Dissolve 2-pyrrolidone and hexanesulfonic acid in the solvent ethyl acetate at a molar ratio of 1:1.5, gradually raise the temperature to 50°C and stir for 8 hours, wash with ethyl acetate after the reaction Unreacted materials were removed and dried under vacuum at 60 °C for 4 h.

[0030] 2. Preparation of ionic liquid: Mix the washed ionic liquid precursor and p-toluenesulfonic acid at a molar ratio of 1:2.05, stir at 80°C for 8h, evaporate at 80°C for 1h after the reaction to obtain a yellow color Viscous liquid.

[0031] In the obtained sulfonic acid functionalized pyrrolidone ionic liquid catalyst, containing mass fraction is 45% pyrrolidone, 50% hexanesulfonic acid, 5% p-toluenesulfonate; the electric pH of ionic liquid catalyst is 1.5, and conductivity is 0.45 S / m; viscosity is 360mPa·s.

Embodiment 2

[0033] 1. Preparation of ionic liquid precursor: Dissolve N-methylpyrrolidone and hexanesulfonic acid in the solvent toluene at a molar ratio of 1:1.1, gradually raise the temperature to 60°C and stir for 7 hours, wash with toluene after the reaction to remove untreated The reacted material was dried under vacuum at 50° C. for 6 h.

[0034] 2. Preparation of ionic liquid: Mix the washed ionic liquid precursor and methanesulfonic acid at a molar ratio of 1:1.8, stir at 60°C for 8h, evaporate at 60°C for 1h after the reaction to obtain a yellow color Viscous liquid.

[0035] In the obtained sulfonic acid functionalized pyrrolidone ionic liquid catalyst, containing mass fraction is 35% pyrrolidone, 55% hexanesulfonic acid, 10% methanesulfonate; the electric pH of ionic liquid catalyst is 1.9, and conductivity is 1.35 S / m; viscosity is 450mPa·s.

Embodiment 3

[0037] 1. Preparation of ionic liquid precursor: Dissolve N-ethylpyrrolidone and hexanesulfonic acid in diethyl ether as a molar ratio of 1:1.5, gradually raise the temperature to 55°C and stir for 8 hours, wash with diethyl ether to remove untreated The reacted material was dried under vacuum at 50° C. for 6 h.

[0038] 2. Preparation of ionic liquid: mix the washed ionic liquid precursor with concentrated sulfuric acid at a molar ratio of 1:1.5, stir at 80°C for 10h, evaporate at 80°C for 0.5h after the reaction to obtain a yellow viscous thick liquid.

[0039] In the obtained sulfonic acid functionalized pyrrolidone ionic liquid catalyst, containing mass fraction is 37% pyrrolidone, 55% hexanesulfonic acid, 8% bisulfate; the electric pH of ionic liquid catalyst is 1.1, and conductivity is 1.30S / m; the viscosity is 520 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com