Expandable universal material and device electrical property testing system

A technology for testing systems and electrical properties, applied in environmental/reliability testing, analyzing materials, testing material strength by applying repetitive force/pulse force, etc. Unable to characterize the electrical properties of polymorphic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

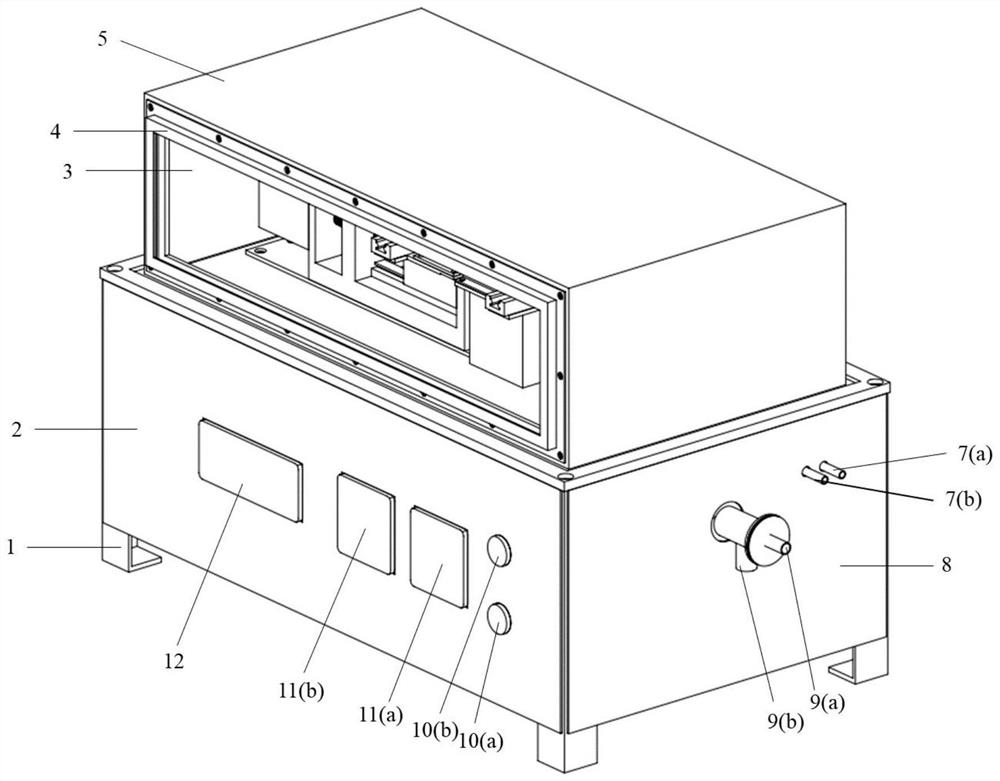

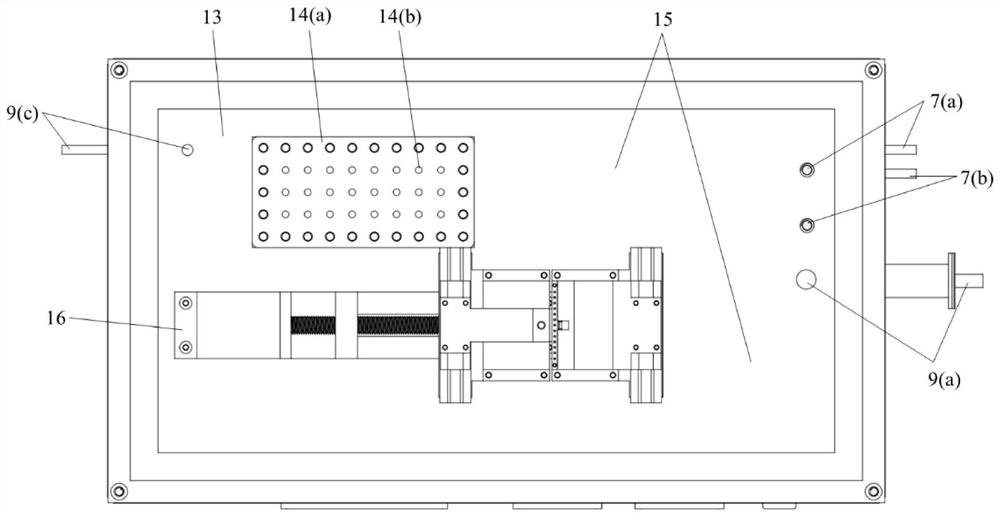

[0068] The expandable general-purpose material and device electrical performance testing system of the present invention includes a temperature control module, a test chamber atmosphere module, a sample clamping module, a sample stretching cycle module, and an electrical performance collection module.

[0069] specific:

[0070] The temperature control module includes a heating water cooling assembly, a control circuit composed of a PID and a relay;

[0071] The cavity atmosphere module includes a vacuum cover, a rubber gasket, etc.;

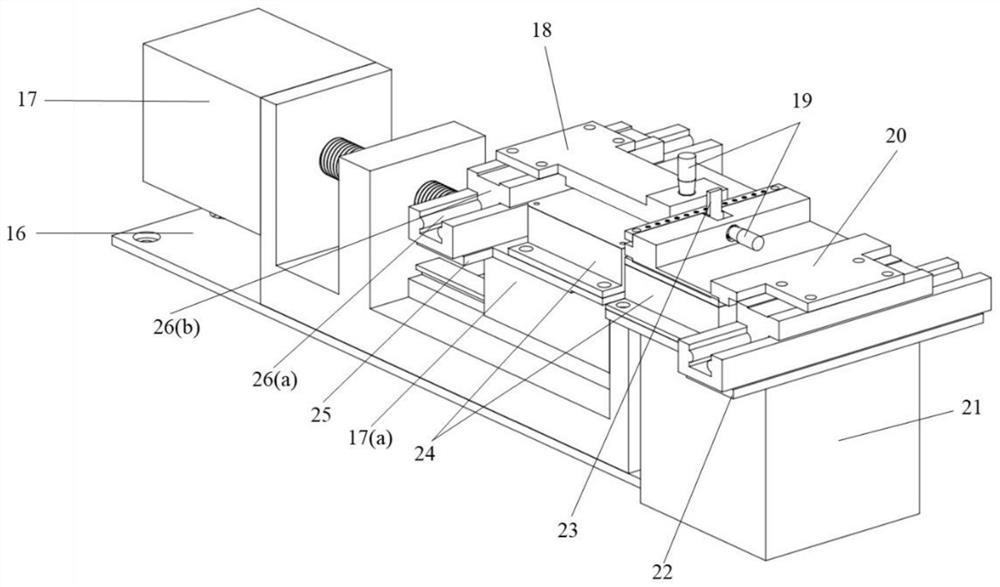

[0072] The sample holding module includes a U-shaped guide rail, a film sample stage and a differential head rod;

[0073] The sample stretching cycle module includes a three-dimensional mobile platform, a stepping motor and a control circuit of the module;

[0074] The electrical performance acquisition module includes temperature, voltage, and current signal acquisition probes and an acquisition card, and can be used in conjunction with a co...

Embodiment 2

[0086] The expandable general-purpose material and device electrical performance testing system of the present invention includes a temperature control module, a test chamber atmosphere module, a sample clamping module, a sample stretching cycle module, and an electrical performance collection module.

[0087] specific:

[0088] The temperature control module includes a heating water cooling assembly, a control circuit composed of a PID and a relay;

[0089] The cavity atmosphere module includes a vacuum cover, a rubber gasket, etc.;

[0090] The sample holding module includes a U-shaped guide rail, a rod-shaped sample stage and a differential head rod;

[0091] The sample stretching cycle module includes a three-dimensional mobile platform, a stepping motor and a control circuit of the module;

[0092] The electrical performance acquisition module includes temperature, voltage, and current signal acquisition probes, an acquisition card and a computer system.

[0093] Prefe...

Embodiment 3

[0104] The expandable general-purpose material and device electrical performance testing system of the present invention includes a temperature control module, a test chamber atmosphere module, a sample clamping module, a sample stretching cycle module, and an electrical performance collection module.

[0105] specific:

[0106] The temperature control module includes a heating water cooling assembly, a control circuit composed of a PID and a relay;

[0107] The cavity atmosphere module includes a vacuum cover, a rubber gasket, etc.;

[0108] The sample holding module includes a U-shaped guide rail, a flexible elastic colloid sample table and a differential head rod;

[0109] The sample stretching cycle module includes a three-dimensional mobile platform, a stepping motor and a control circuit of the module;

[0110] The electrical performance acquisition module includes temperature, voltage, and current signal acquisition probes, an acquisition card and a computer system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com