Rotary stripping rate tester and using method

A peel rate and tester technology, applied in the field of rotary peel rate testers, can solve the problems of increased test error, low test efficiency, low accuracy and repeatability of results, and achieves good wear resistance, rich variety Test conditions, the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

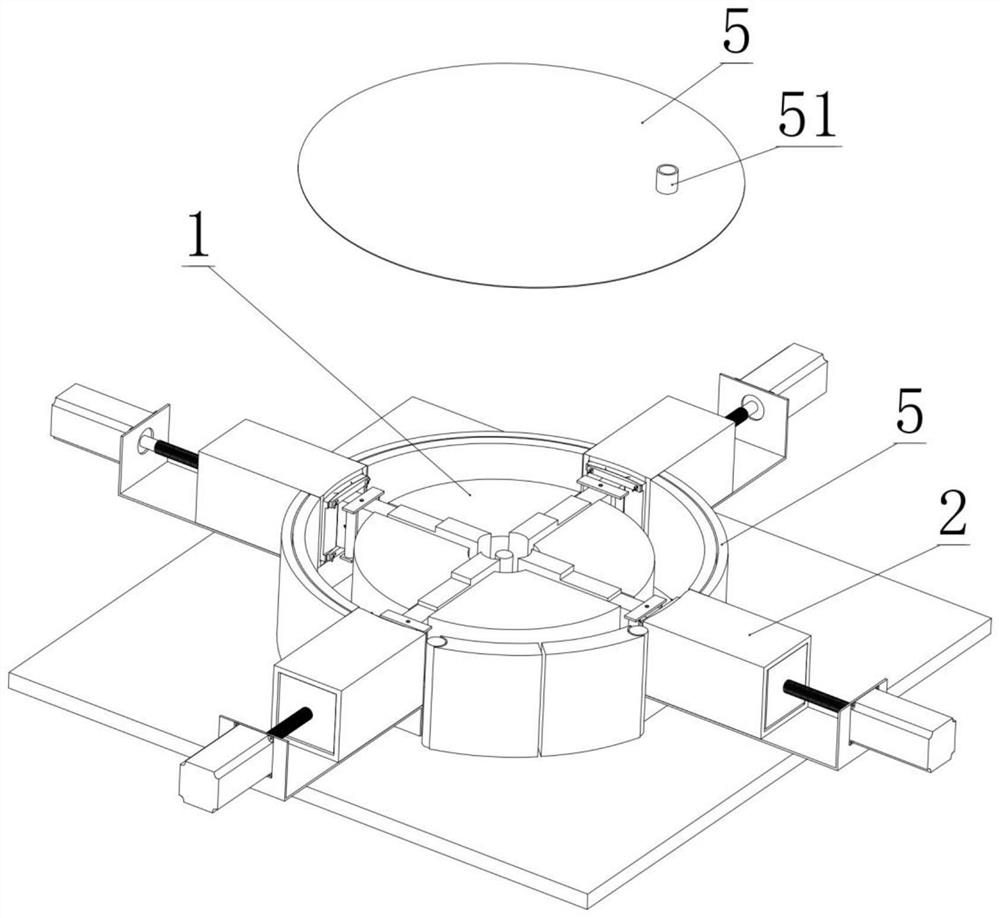

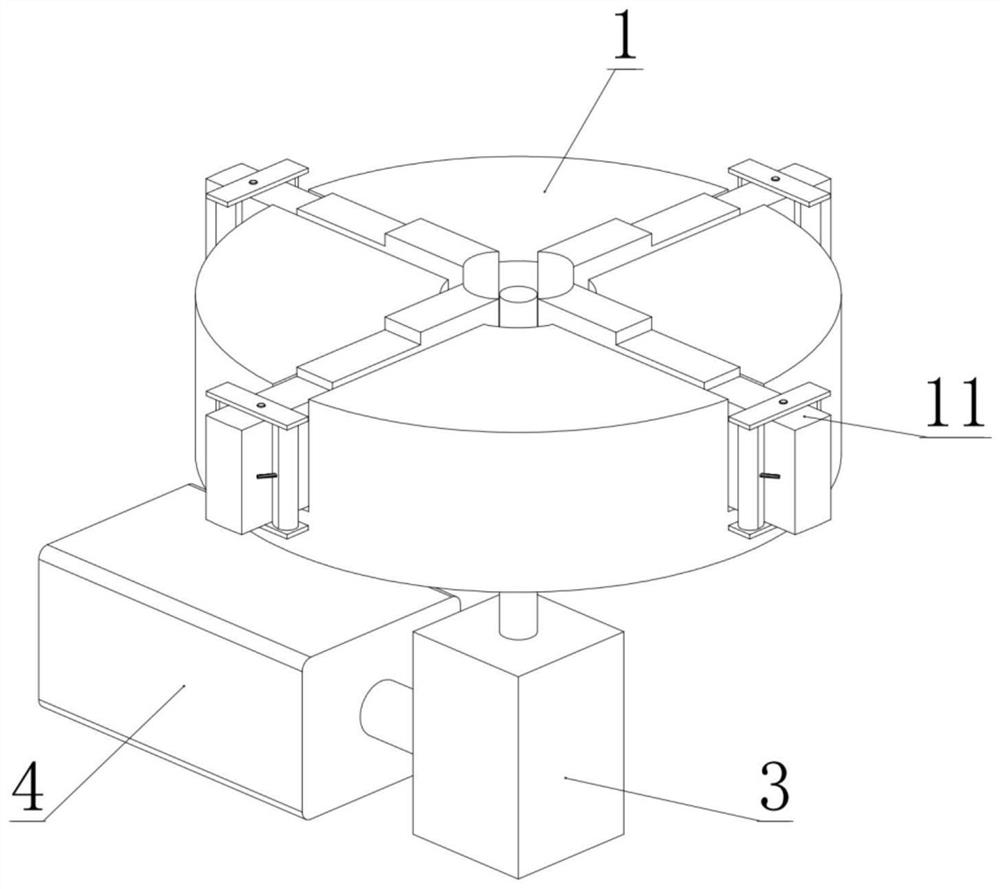

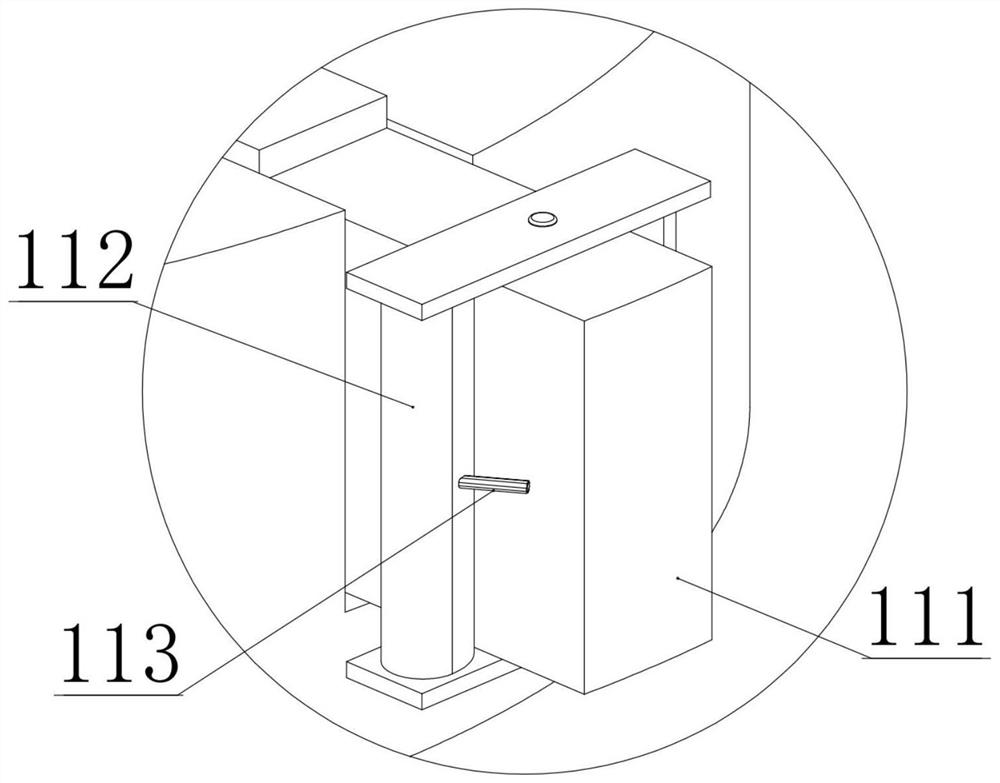

[0036] A rotary peel rate tester such as Figures 1 to 6 As shown, it includes a rotatable turntable 1 and a set of specimen clamping devices 2 distributed around the turntable 1; a set of fixed assemblies 11 that rotate with the turntable 1 are provided on the side of the turntable 1; the fixed assembly 11 can fix the friction material, And make the friction surface of the friction material face the specimen holding device 2; the specimen holding device 2 includes a pressing block 21 that can elastically slide along the radial direction of the turntable 1, and the end face of the pressing block 21 facing the turntable 1 is marked as a pressing end face, The test piece can be fixed on the pressing end surface; the test piece holding device 2 also includes a compression spring 25 that pushes the pressing block 21 to the turntable 1; The portion 29 determines the limit position where the pressing block 21 slides toward the turntable 1 .

[0037] In this embodiment, the fixing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com