Linear compressor

a linear compressor and compressor technology, applied in the direction of machines/engines, positive displacement liquid engines, piston pumps, etc., can solve the problems of increased manufacturing costs and difficult assembly work, and achieve the reduction of manufacturing costs and assembly time of linear compressors, simplified oil supply structures, and reduced oil supply parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

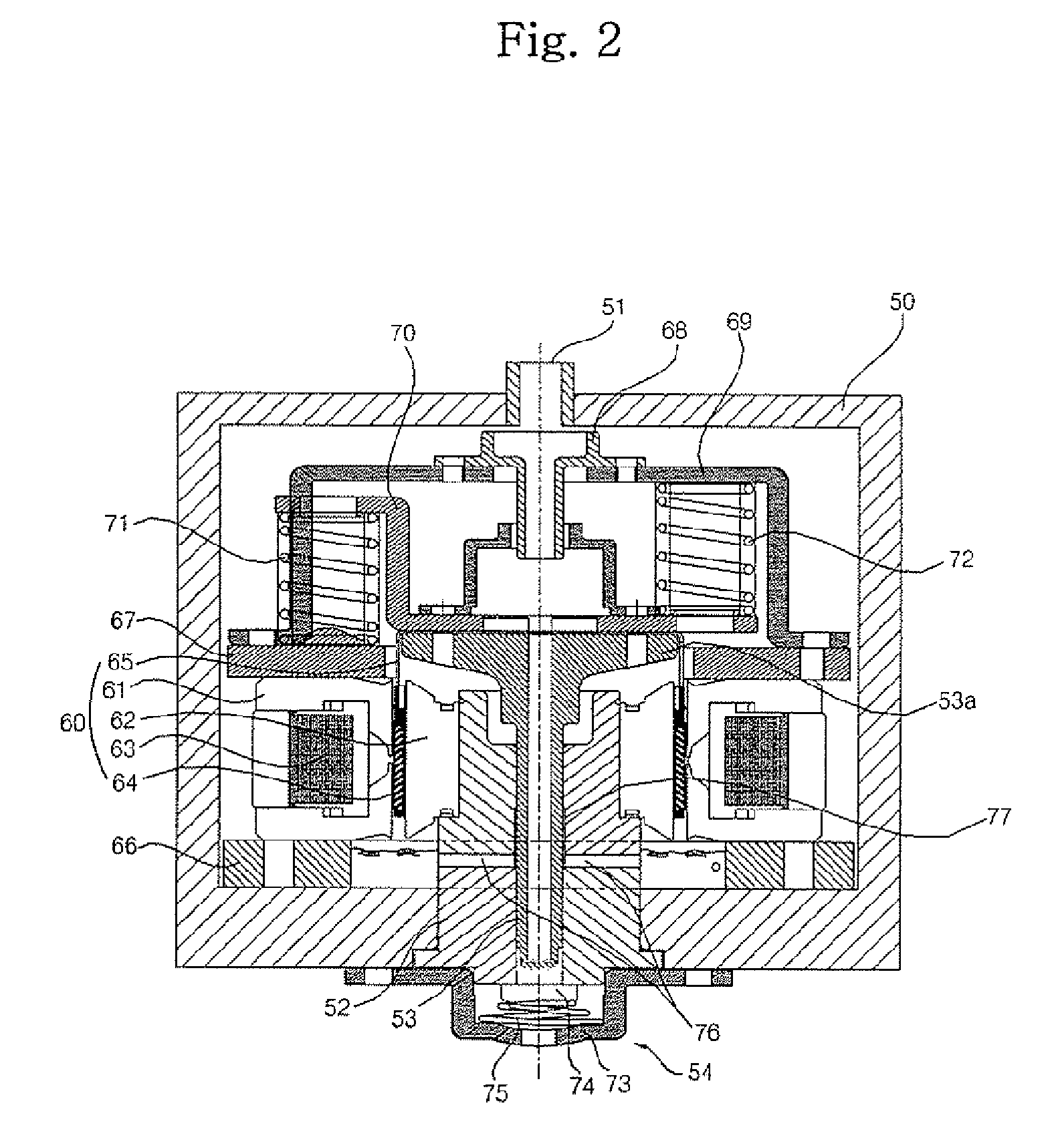

[0039]FIG. 2 is a sectional view illustrating a linear compressor according to the present invention.

[0040] As shown in FIG. 2, the linear compressor according to the first embodiment of the present invention comprises a shell 50 formed with a suction port 51 and a discharge port, an elongated cylinder 52 extending vertically in the shell 50, a piston 53 disposed in the cylinder 52 to perform linear reciprocating movements in the cylinder 52, a linear motor 60 to linearly reciprocate the piston 53, a discharge unit assembly 54 mounted to the discharge port at the outside of the shell 50 to allow the fluid, compressed in the cylinder 52, to be discharged through the discharge unit assembly 54, and an oil supply device formed in the cylinder 52 to supply oil into a space between the cylinder 52 and the piston 53.

[0041] The shell 50 has a cylindrical structure, and is provided at the top thereof with the suction port 51 and at the bottom thereof with the discharge port.

[0042] The cyl...

second embodiment

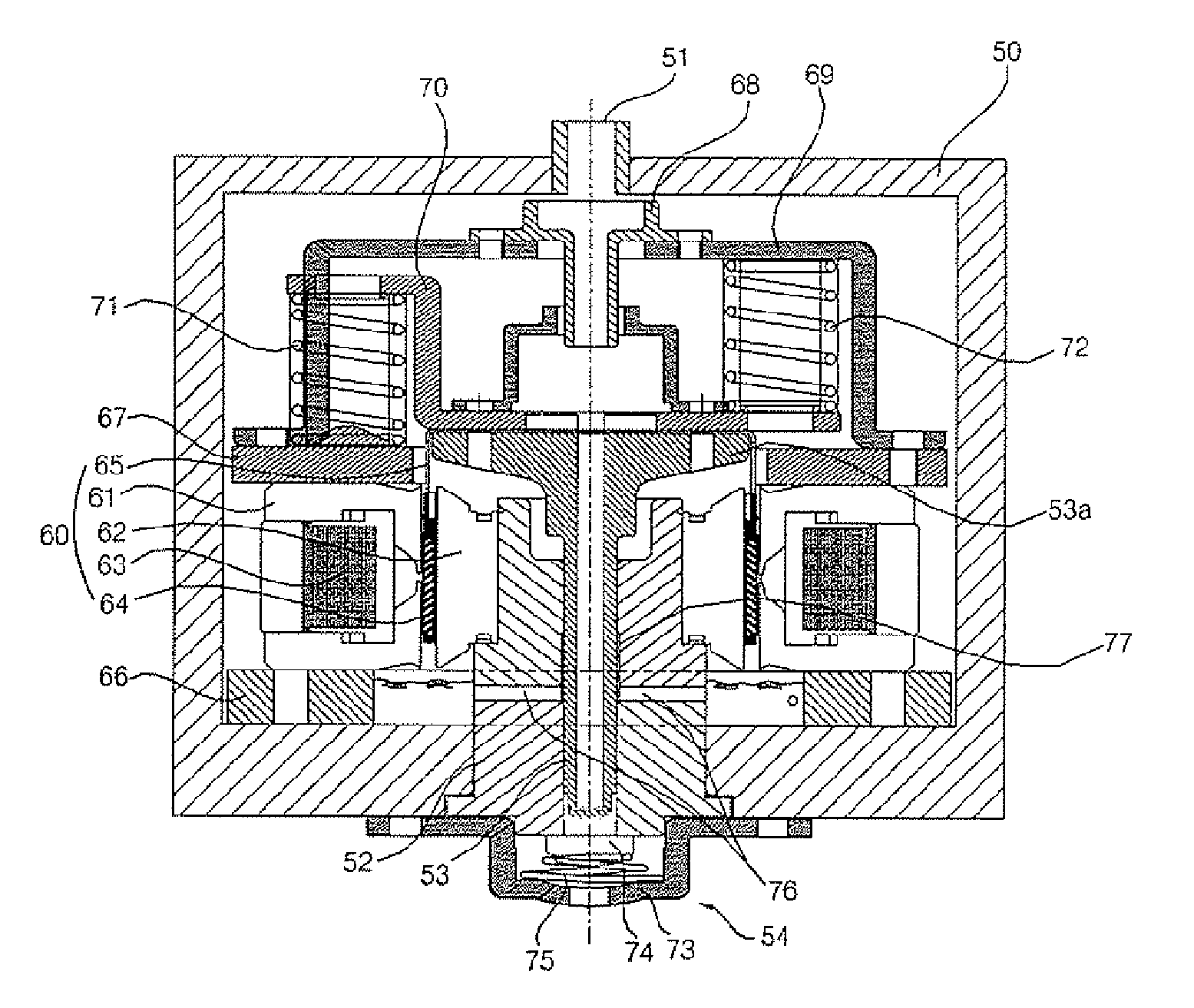

[0064]FIG. 3 is a sectional view illustrating a linear compressor according to the present invention.

[0065] As shown in FIG. 3, the linear compressor according to the second embodiment of the present invention comprises a shell 80 formed with a suction port 81 and a discharge port, an elongated cylinder 82 extending vertically in the shell 80, a piston 83 disposed in the cylinder 82 to perform linear reciprocating movements, a linear motor 84 to linearly reciprocate the piston 83 up and down, a discharge unit assembly 85 mounted to the discharge port at the outside of the shell 80 to allow the fluid, compressed in the cylinder 82, to be discharged through the discharge unit assembly 35, and an oil supply device formed in the cylinder 82 to supply oil into a space between the cylinder 82 and the piston 83.

[0066] In the present embodiment, a motor holder 90 is provided around the cylinder 82 to secure the linear motor 84.

[0067] The motor holder 90 has a cylindrical shape, and is rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com