Assembled shelf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

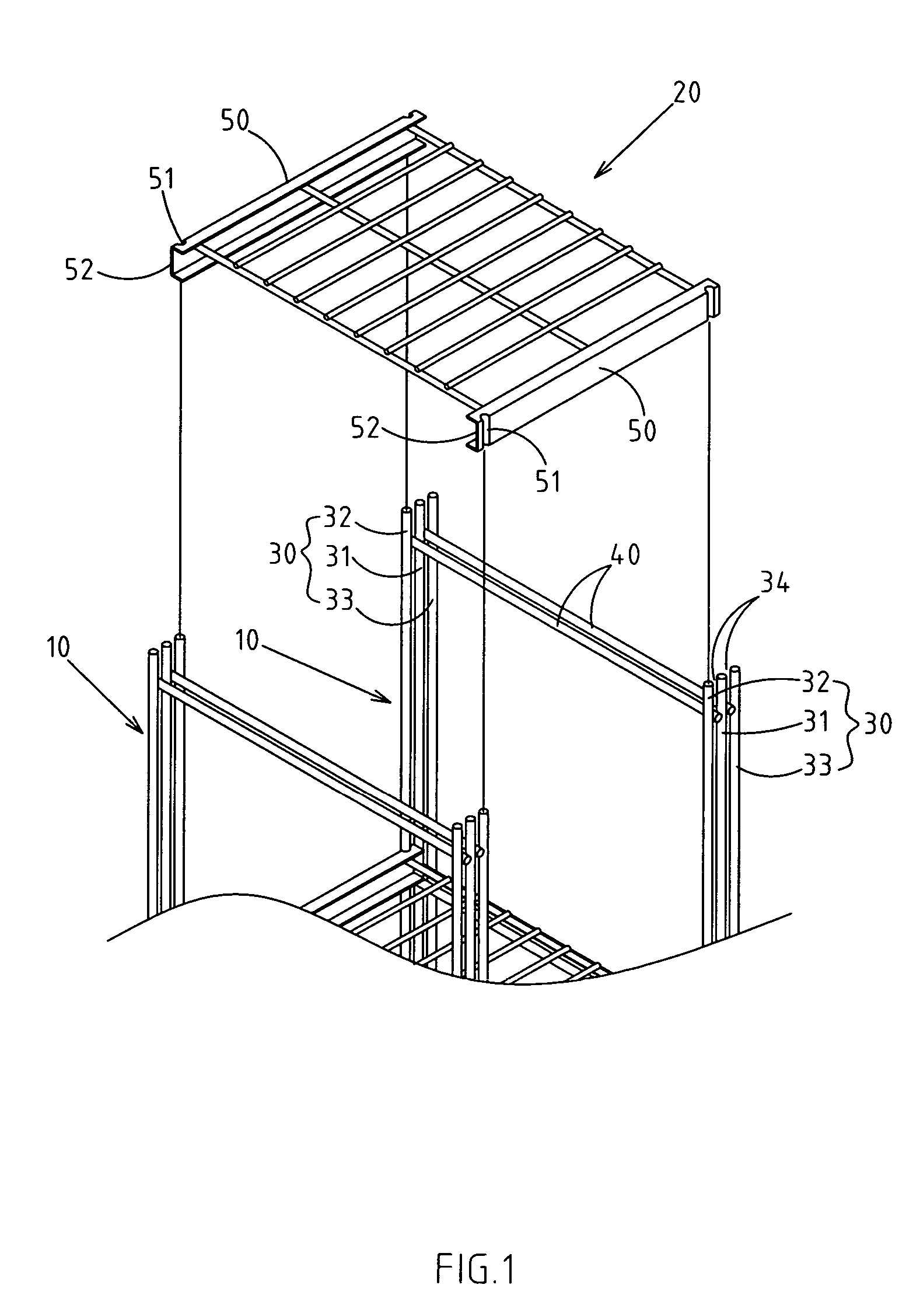

[0035] The features and the advantages of the present invention will be more readily understood upon a thoughtful deliberation of the following detailed description of a preferred embodiment of the present invention with reference to the accompanying drawings.

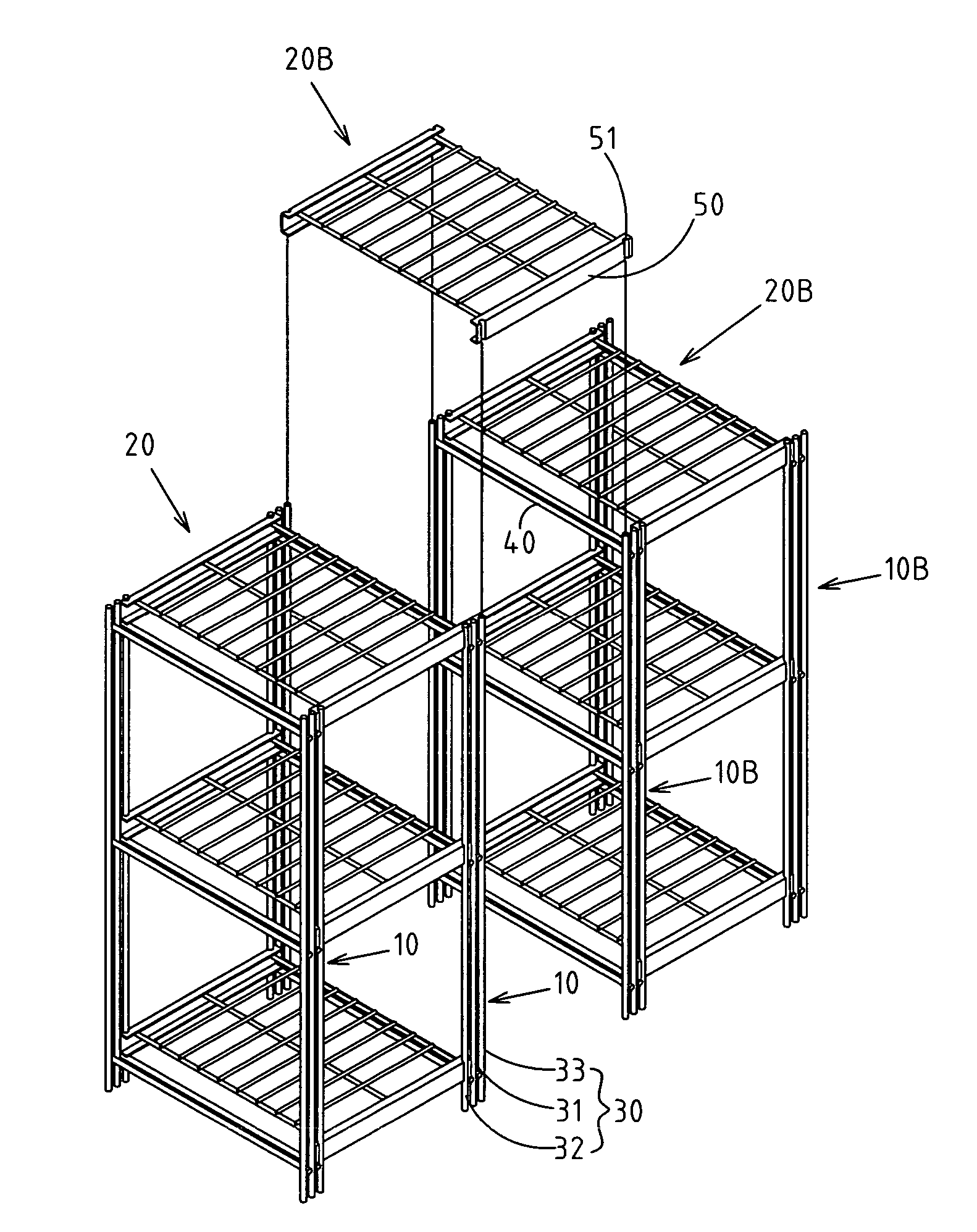

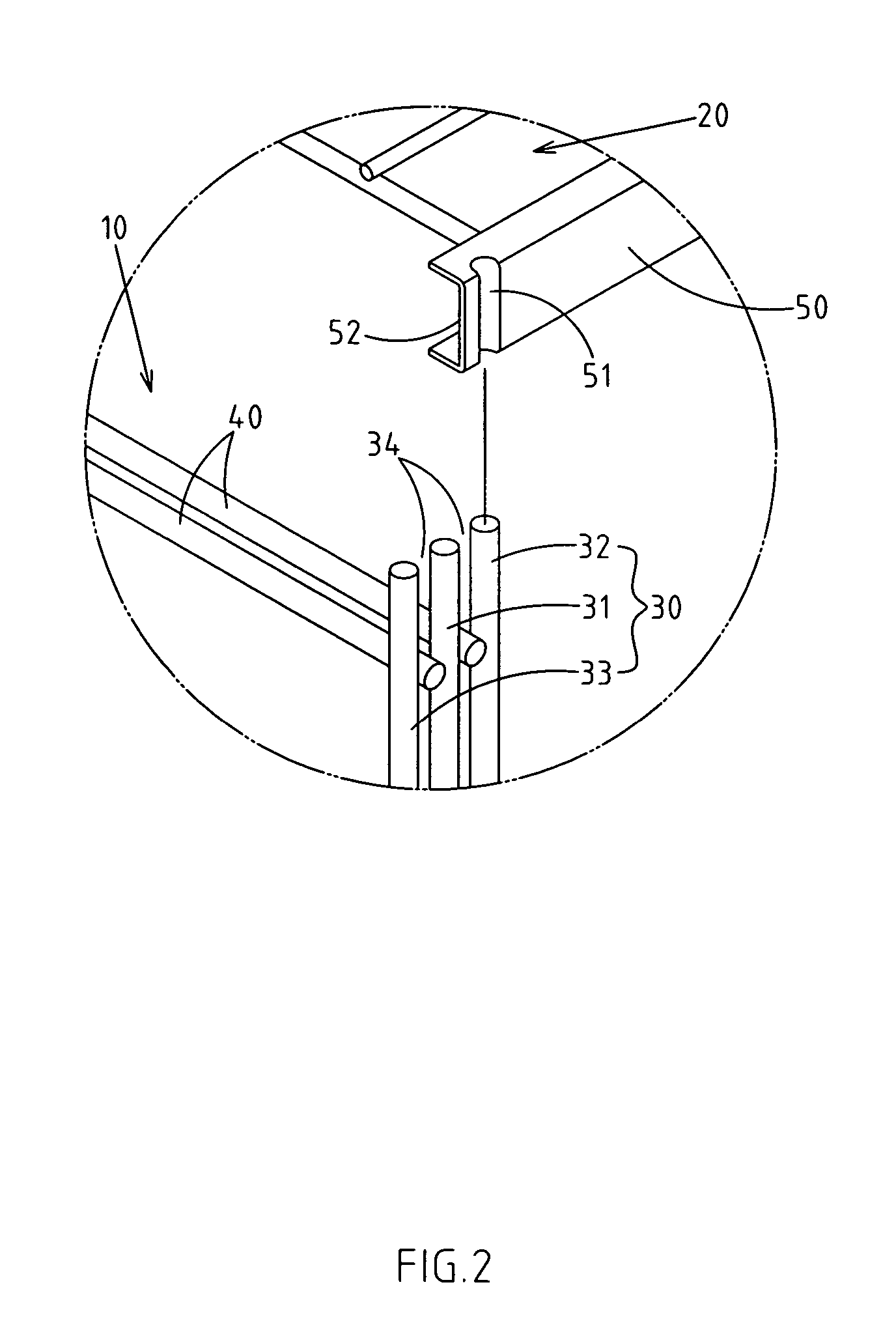

[0036] As shown in FIGS. 1-3, there is the first embodiment of the improved structure of assembled shelf. The main frame comprises two vertical side racks 10 and several sets of shelves 20. A shelf is placed between the two vertical side racks 10, and the fixed frame (connected by welding) is the vertical side rack made by a vertical bar 30 and horizontal bar 40. The horizontal bar 40 is placed on the pre-determined height of the shelf 20 for the shelf 20.

[0037] A vertical bar 30 of the vertical side rack 10 includes a main bar31 and an inner / outer secondary bar 3233. The inner / outer secondary bar is placed inside and outside of the main bar 31, and the main bar 31 is spaced between the inner / outer secondary bar 3233. The spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com