Robust sand screen for oil and gas wells

a sand screen and oil and gas well technology, applied in the direction of drinking water installation, borehole/well accessories, construction, etc., can solve the problems of incomplete screen, marginally less productive well, etc., and achieve the effect of less erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

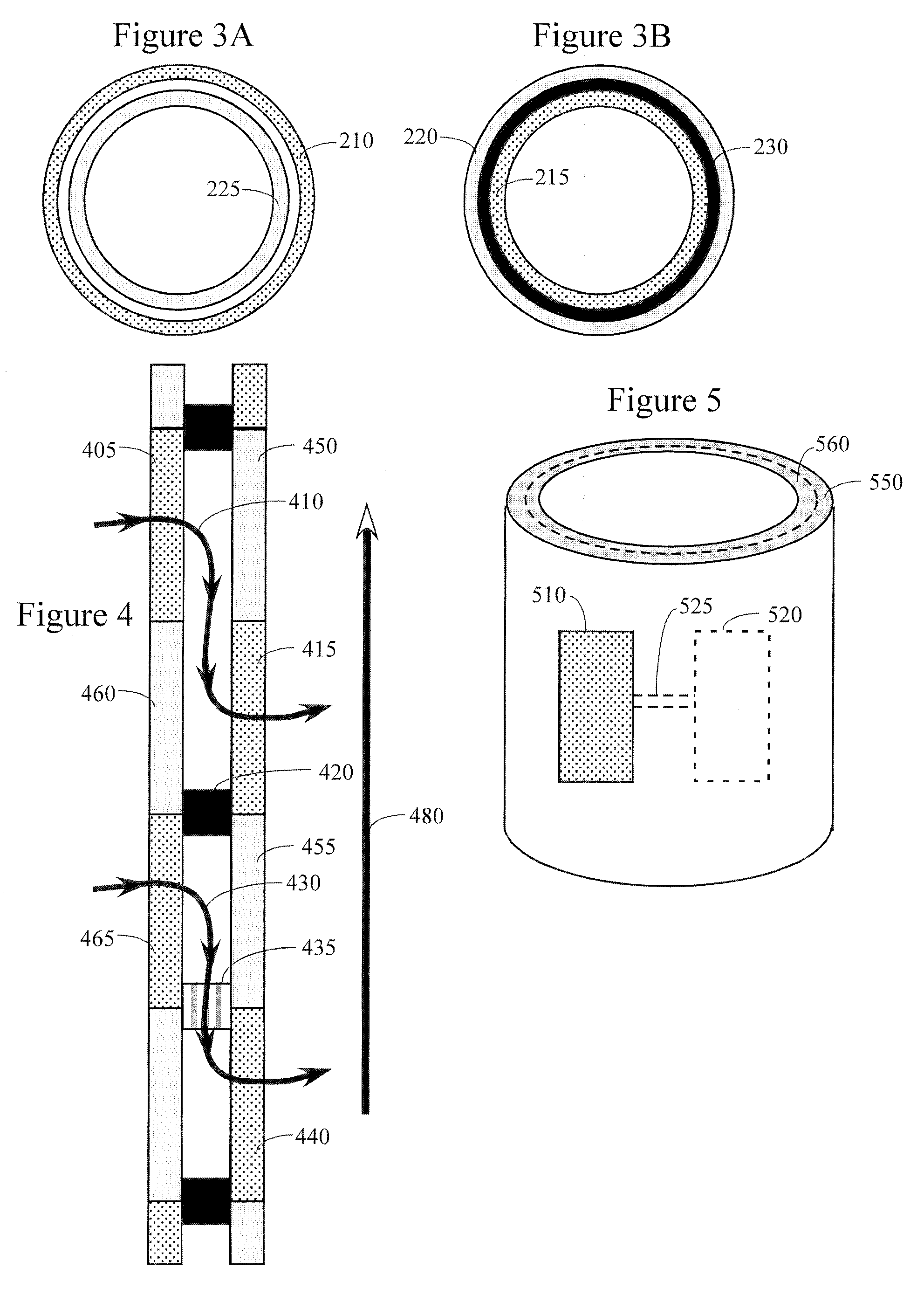

[0025] According to a preferred aspect of the instant invention, the instant robust sand screen module 100 will be most useful in the completion of production or injection wells including, for example, water injectors, gas injectors, or mostly oil and gas producers will be suitable for use with the instant invention. The instant invention will typically be used in connection with well completions in formations that have the potential to produce sand absent some sort of sand preventive technology.

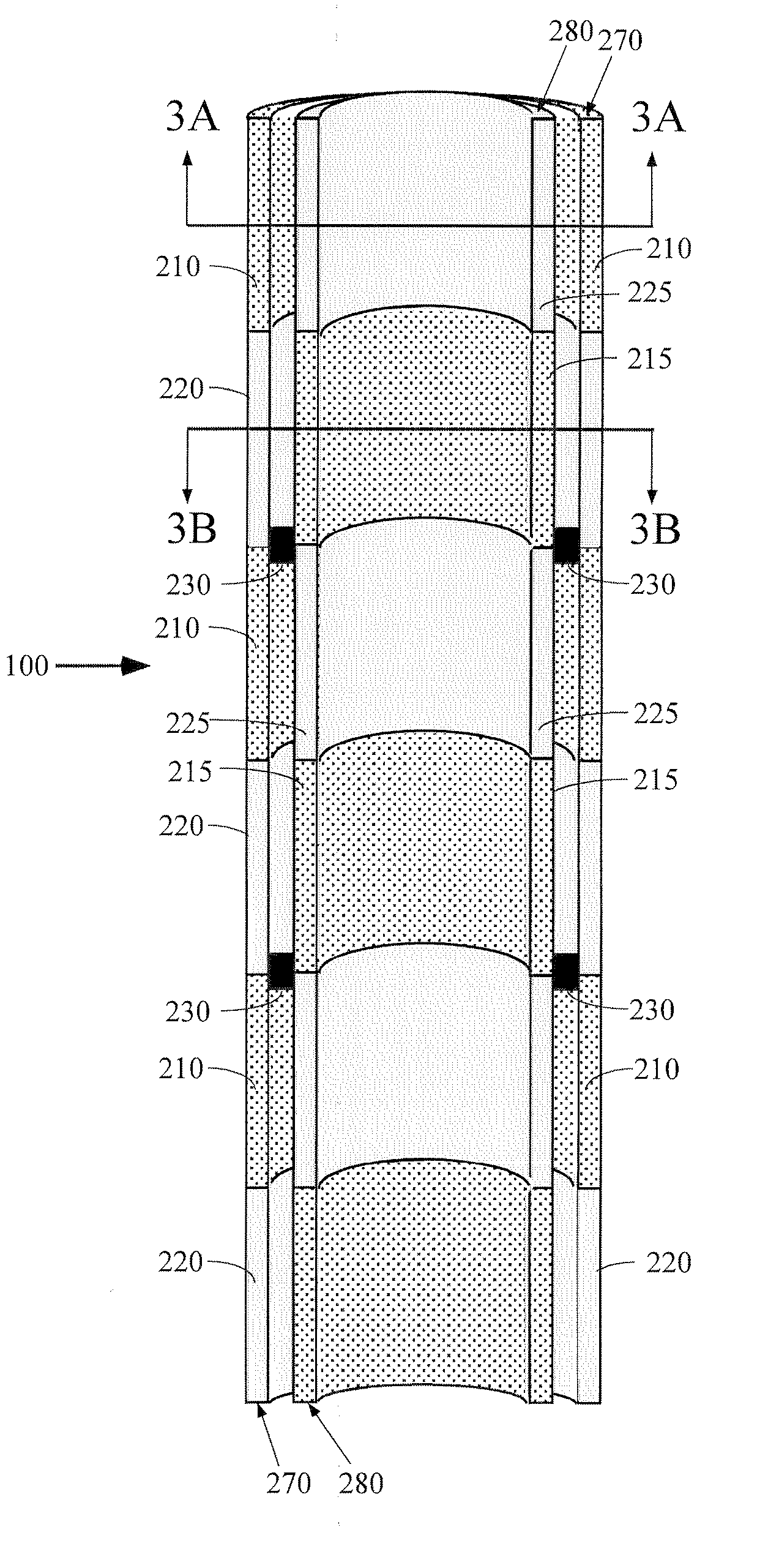

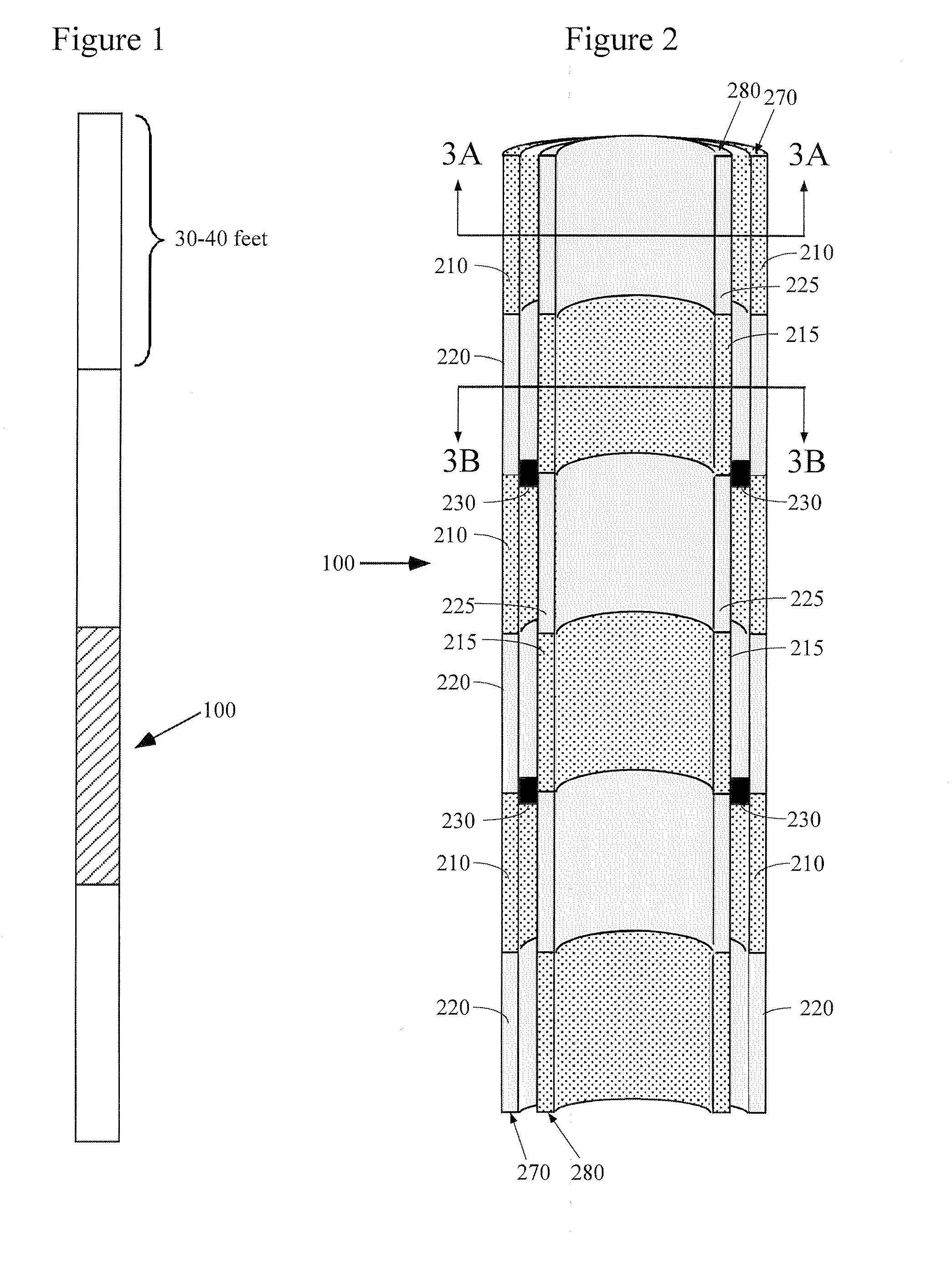

[0026] According to a first preferred embodiment and as is generally indicated in FIG. 1, the instant invention 100 will be preferably be installed as one component of a section of a well completion. However, it should be clear that multiple sections of the invention could be used where, for example, the potential sand problem extends over some distance (e.g., in a horizontal well). In a typical arrangement, the instant invention 100 will preferably be about 30-40 feet in length. One or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com