Sewing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

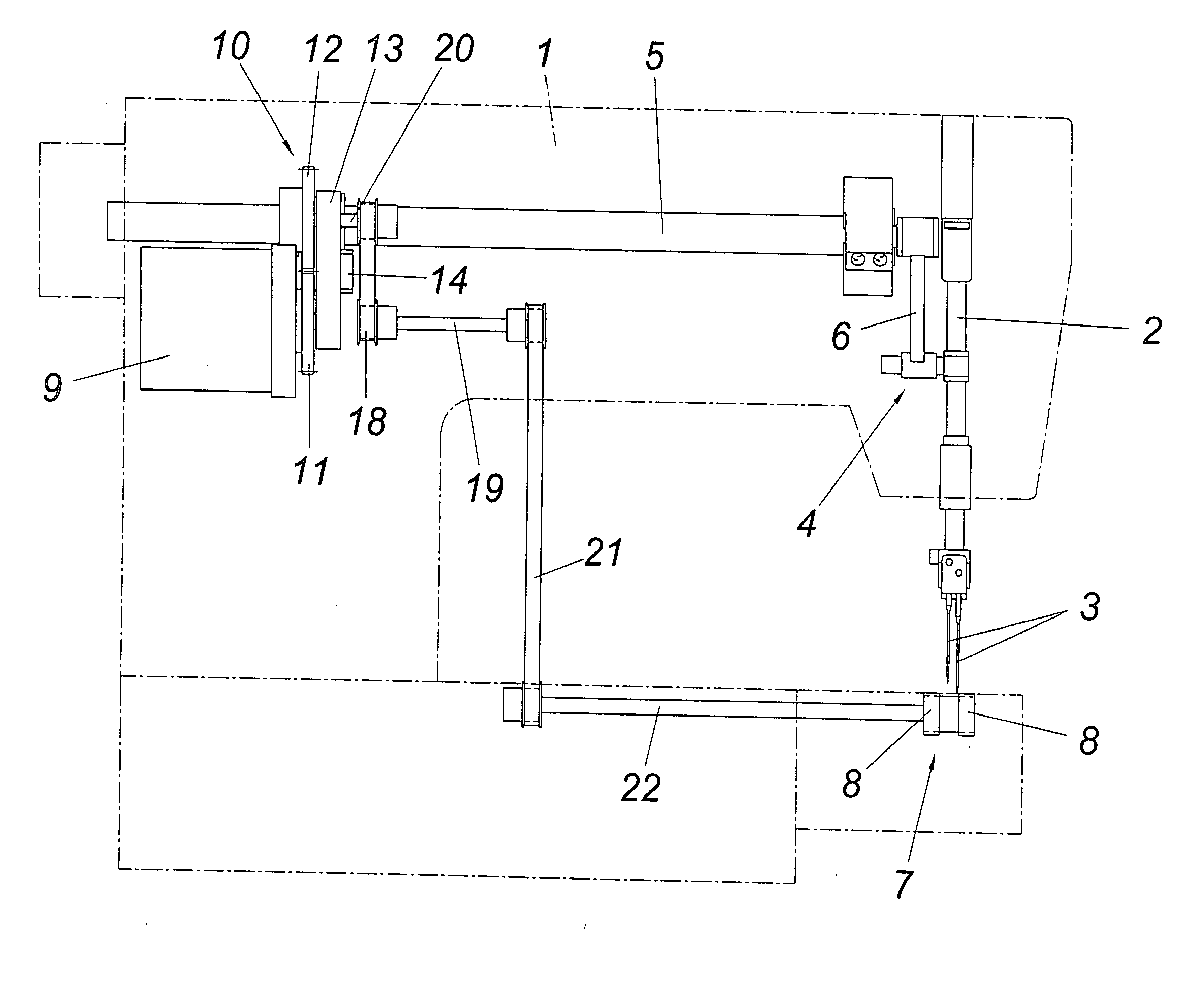

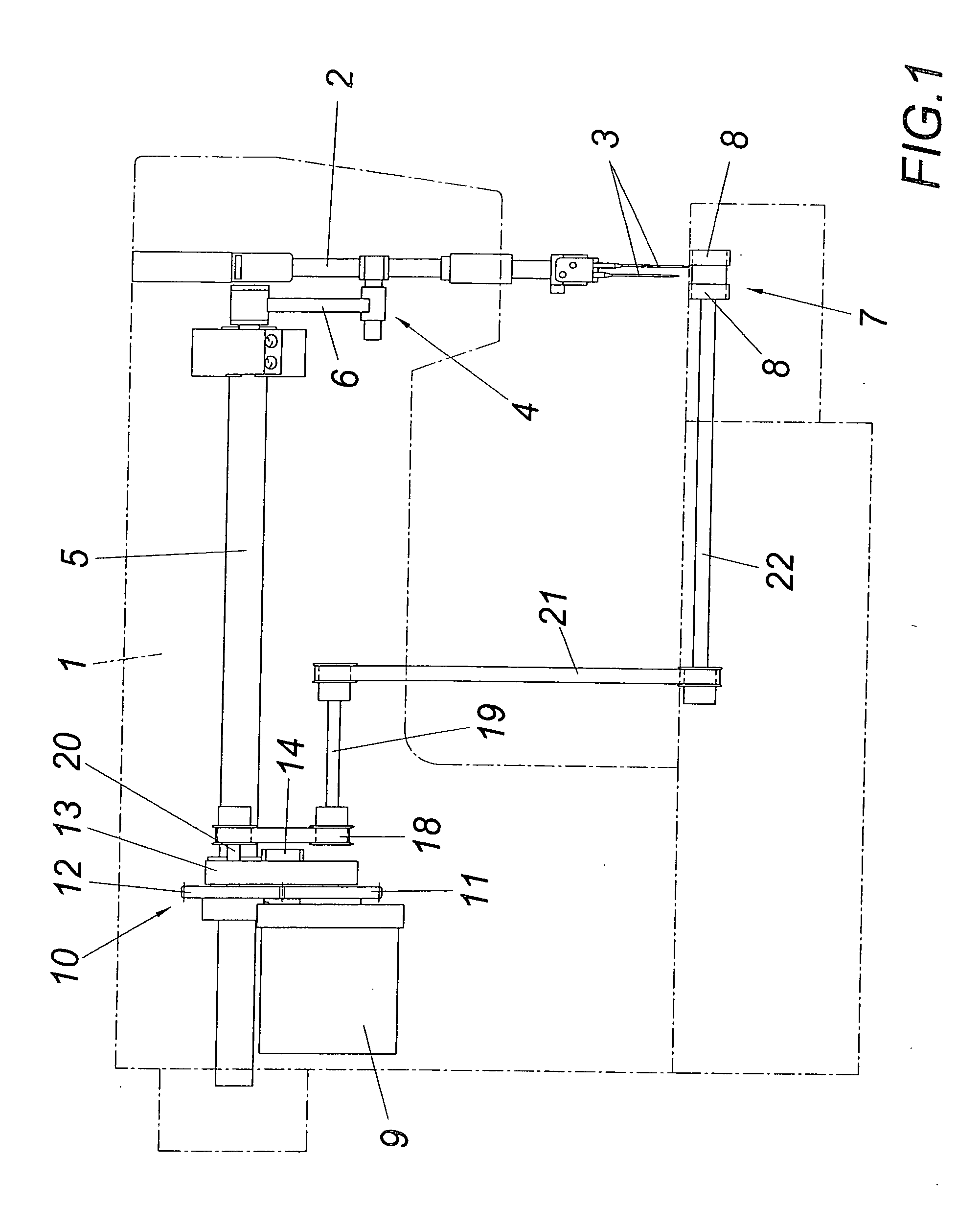

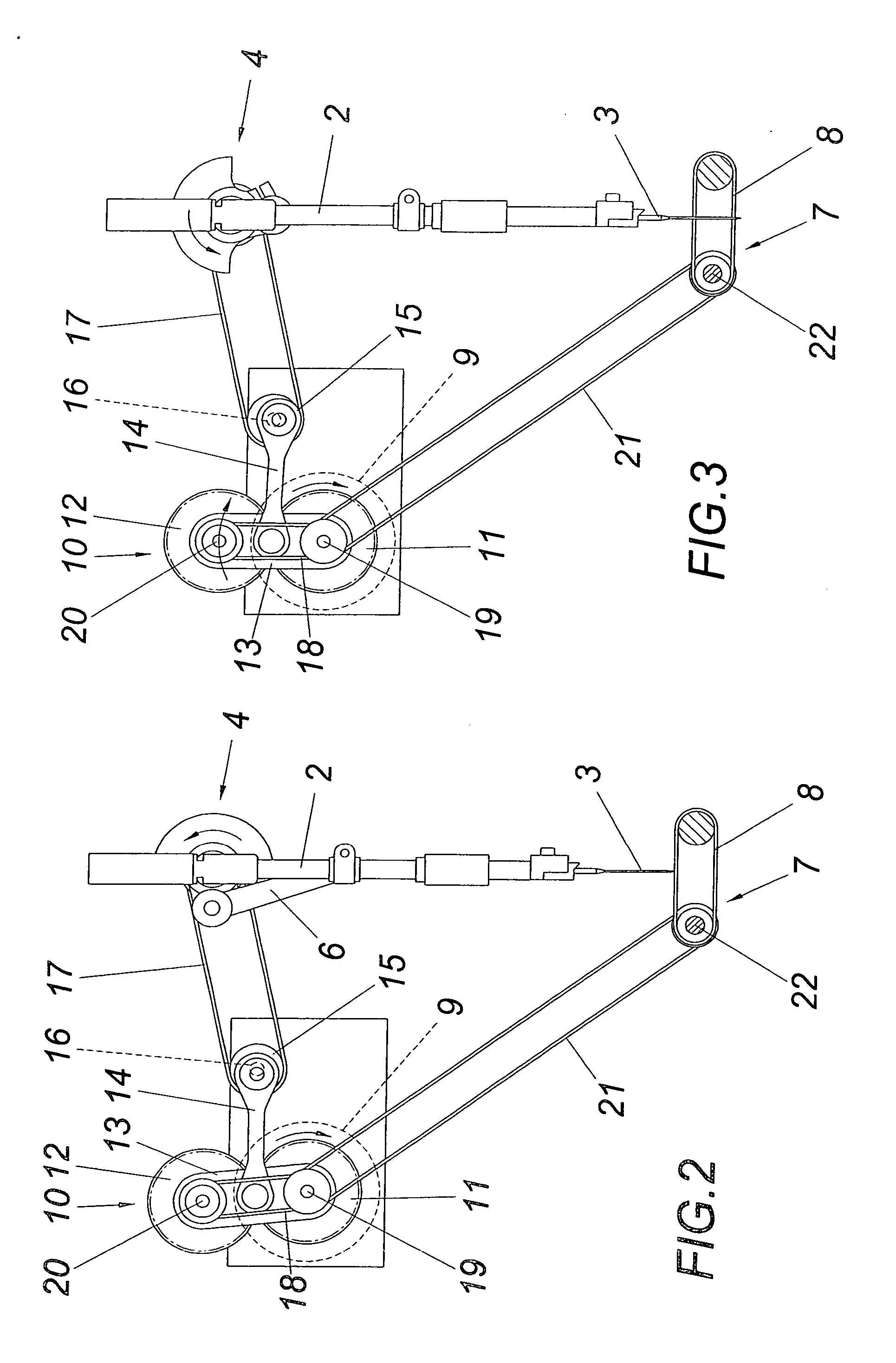

[0012] The sewing machine 1, which is only indicated with the dot-dash line, comprises a needle bar 2 for receiving sewing needles 3 and a sewing needle drive 4 which consists of a drive shaft 5 and a crank mechanism 6 which acts upon the needle bar 2. A belt conveyor 7 is provided for the forward feed of the garment, which conveyor is composed of two parallel conveyor belts 8 between which the needles 3 penetrate the garment. The drive for the belt conveyor 7 is derived from a continuous rotational drive 9 which is preferably driven electrically and is arranged on a base plate. An intermediate drive 10 is driven by said rotational drive, which intermediate drive comprises two mutually combing gearwheels 11 and 12. While the gearwheel 11 on the driven side of the intermediate drive 10 is fixedly situated on the driven shaft of rotational drive 9, the gearwheel 12 on the driven side is rotatably held in a fixed link 13 which is held in a freely rotatable manner on the driven shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com