Integrated hydrocarbon cracking and product olefin cracking

a technology of hydrocarbon cracking and product olefin, applied in the field of hydrocarbon processing, can solve the problems of general failure of the processing scheme and arrangement in the prior art, and achieve the effect of increasing the yield of c2 and c3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A heavy hydrocarbon feedstock can be cracked to produce and process an effluent comprising a range of hydrocarbon products including C4-C7 olefins. At least a portion of such C4-C7 olefins can subsequently be cracked to produce additional C2 and C3 olefins.

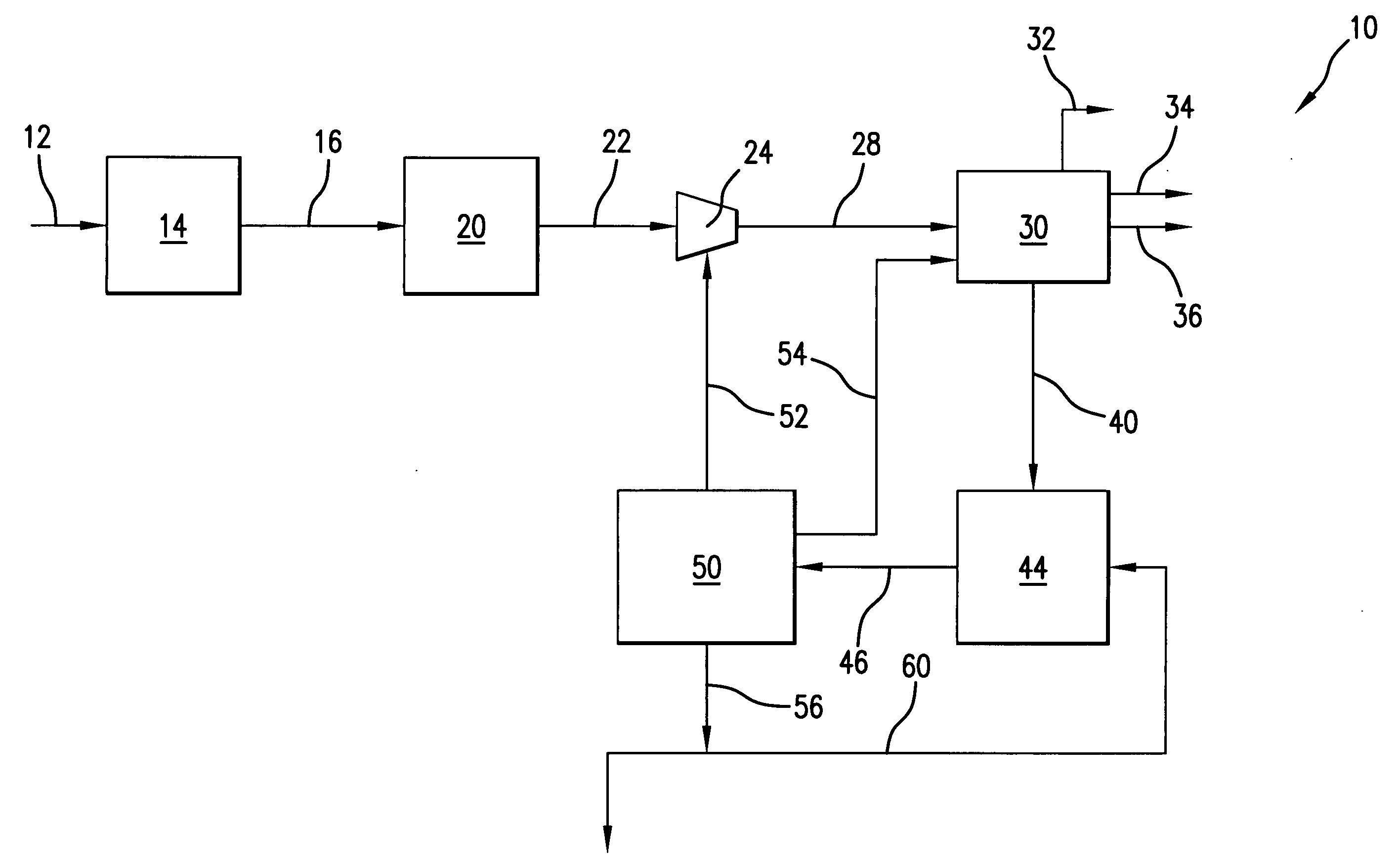

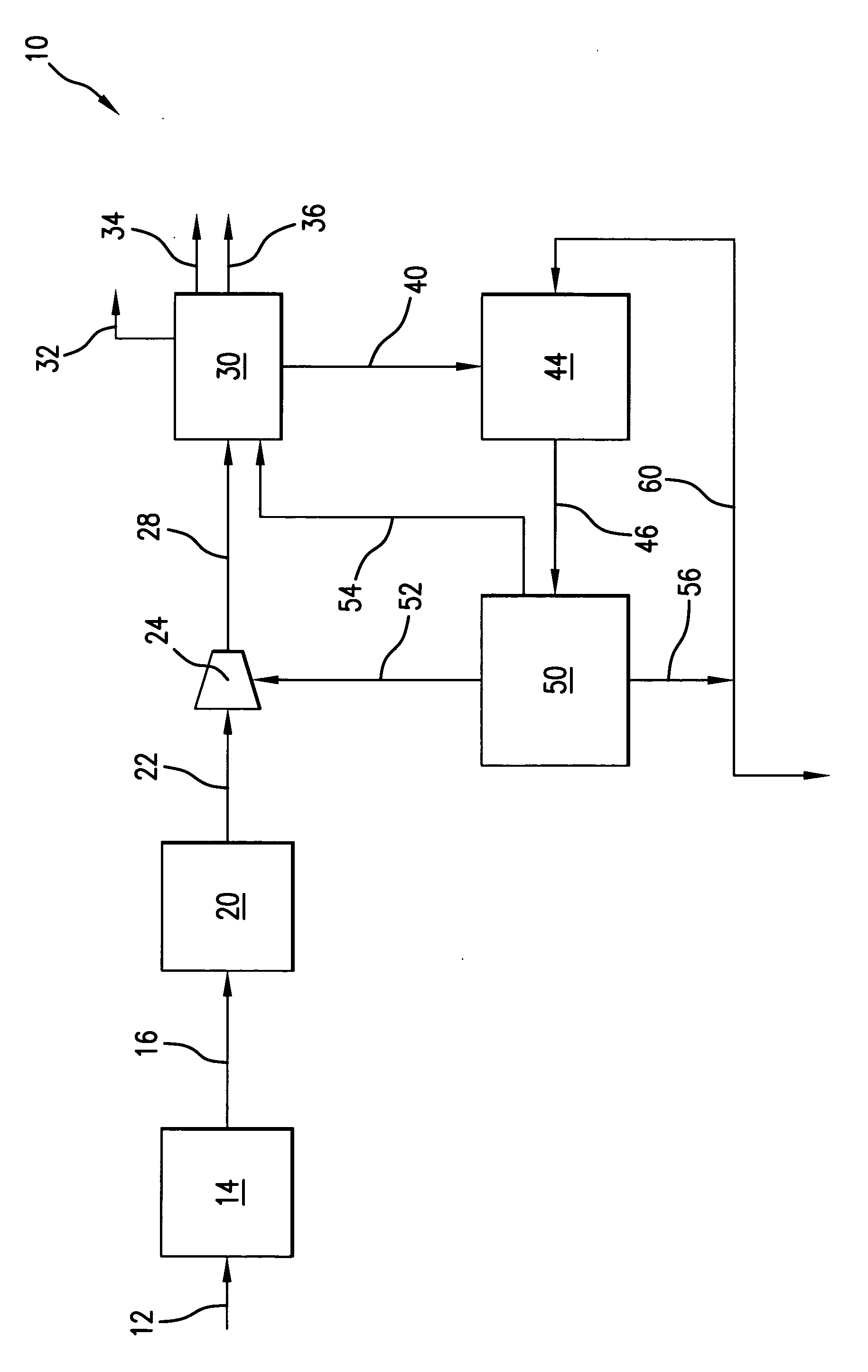

[0016] The FIGURE schematically illustrates a system, generally designated by the reference numeral 10, for the integrated processing of a heavy hydrocarbon feedstock to produce or result in an increased relative amount of light olefins in accordance with one embodiment.

[0017] More particularly, in the system 10, a suitable heavy hydrocarbon feedstock is introduced via a feed line 12 into a fluidized catalytic cracking section 14 wherein the heavy hydrocarbon feedstock contacts with a hydrocarbon cracking catalyst in a primary fluidized bed reactor to produce a hydrocarbon effluent comprising a range of hydrocarbon products including C4-C7 olefins.

[0018] Suitable fluidized catalytic cracking sections for use in the pract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| gas concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com