Golf swing muscle strengthener

a swing muscle and strengthening technology, applied in the field of golf, can solve the problems of increasing the club and requiring significant muscular activity, and achieve the effects of promoting a straight leading arm, reducing the risk of injury, and increasing the ability to bear more for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

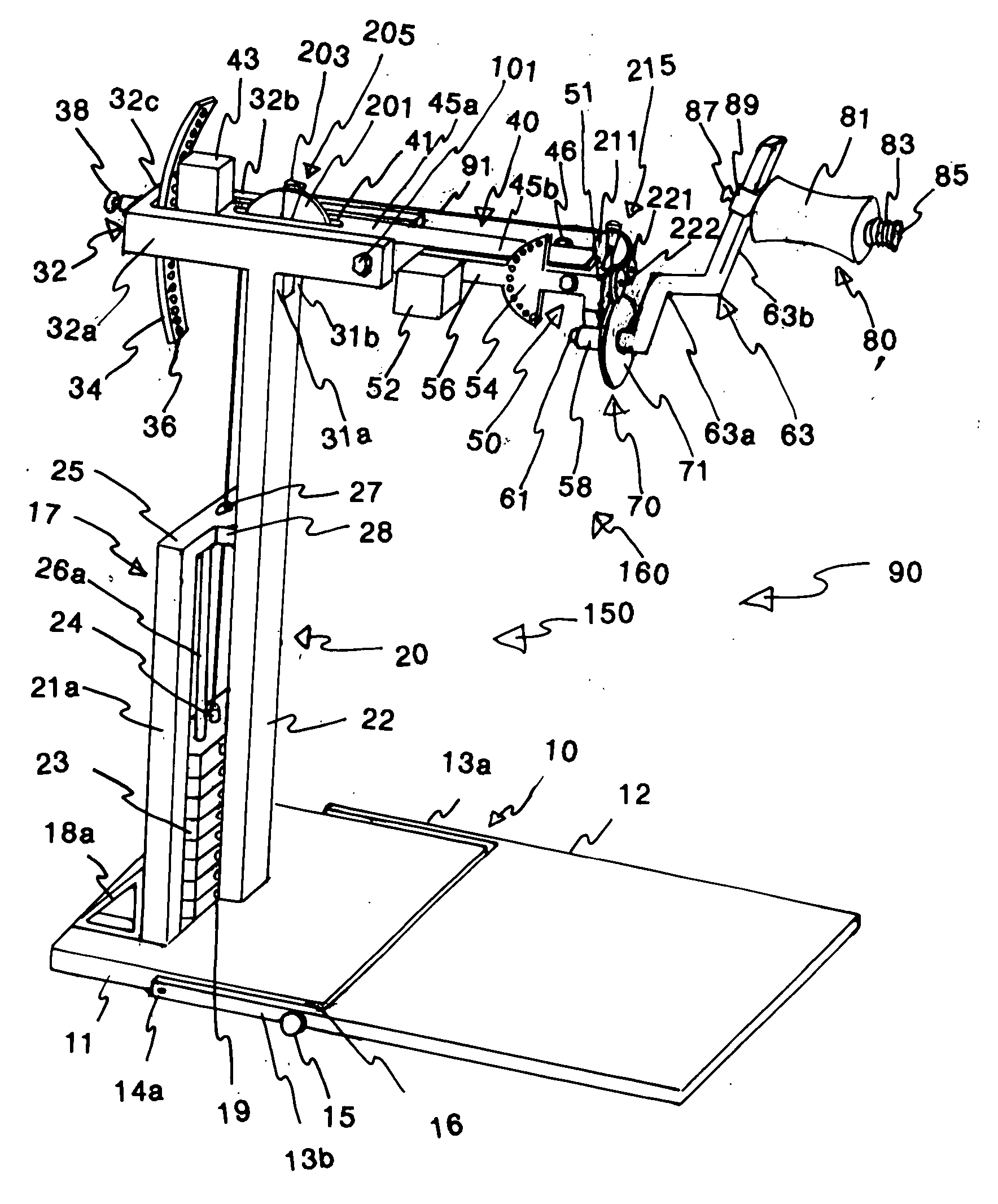

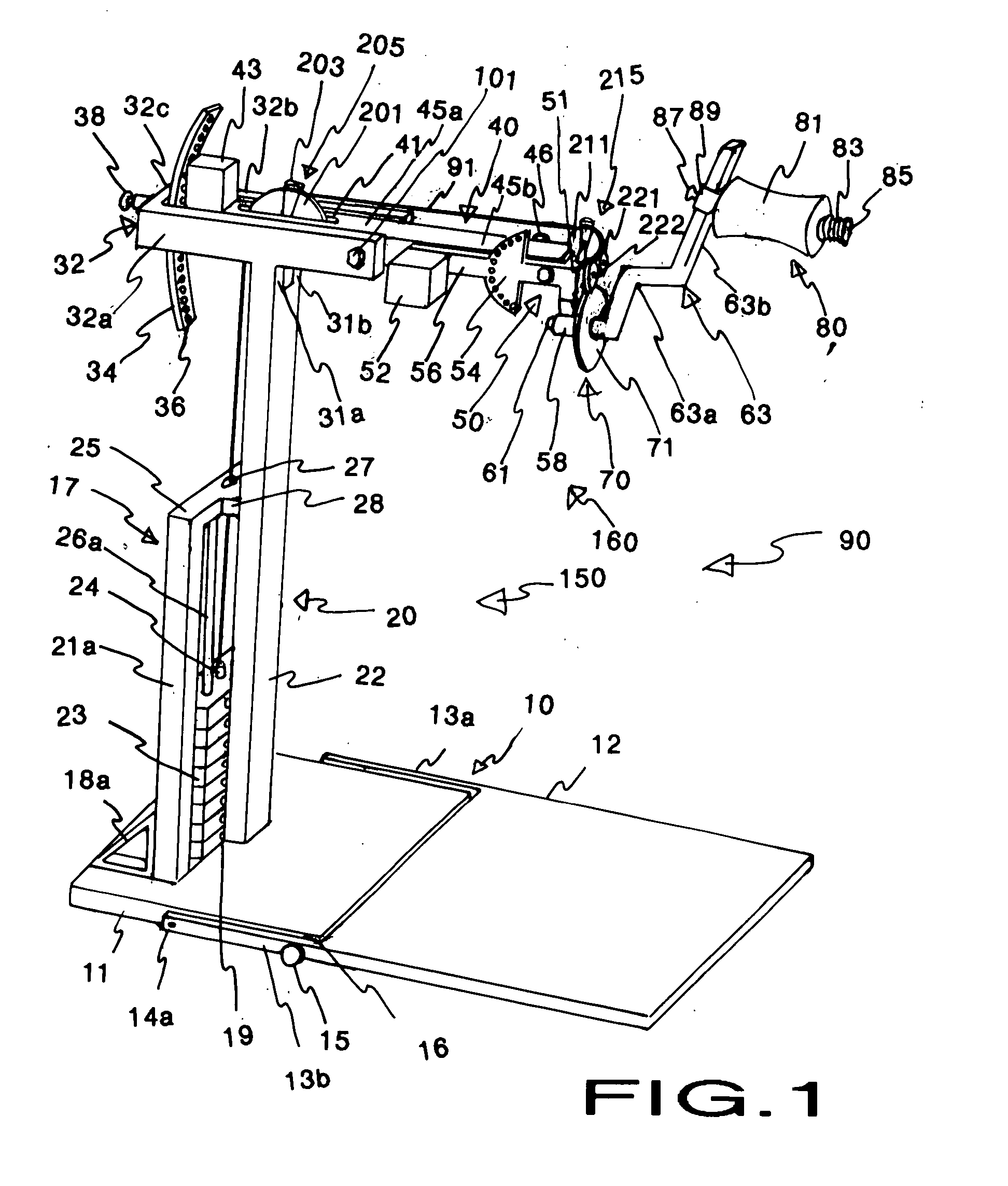

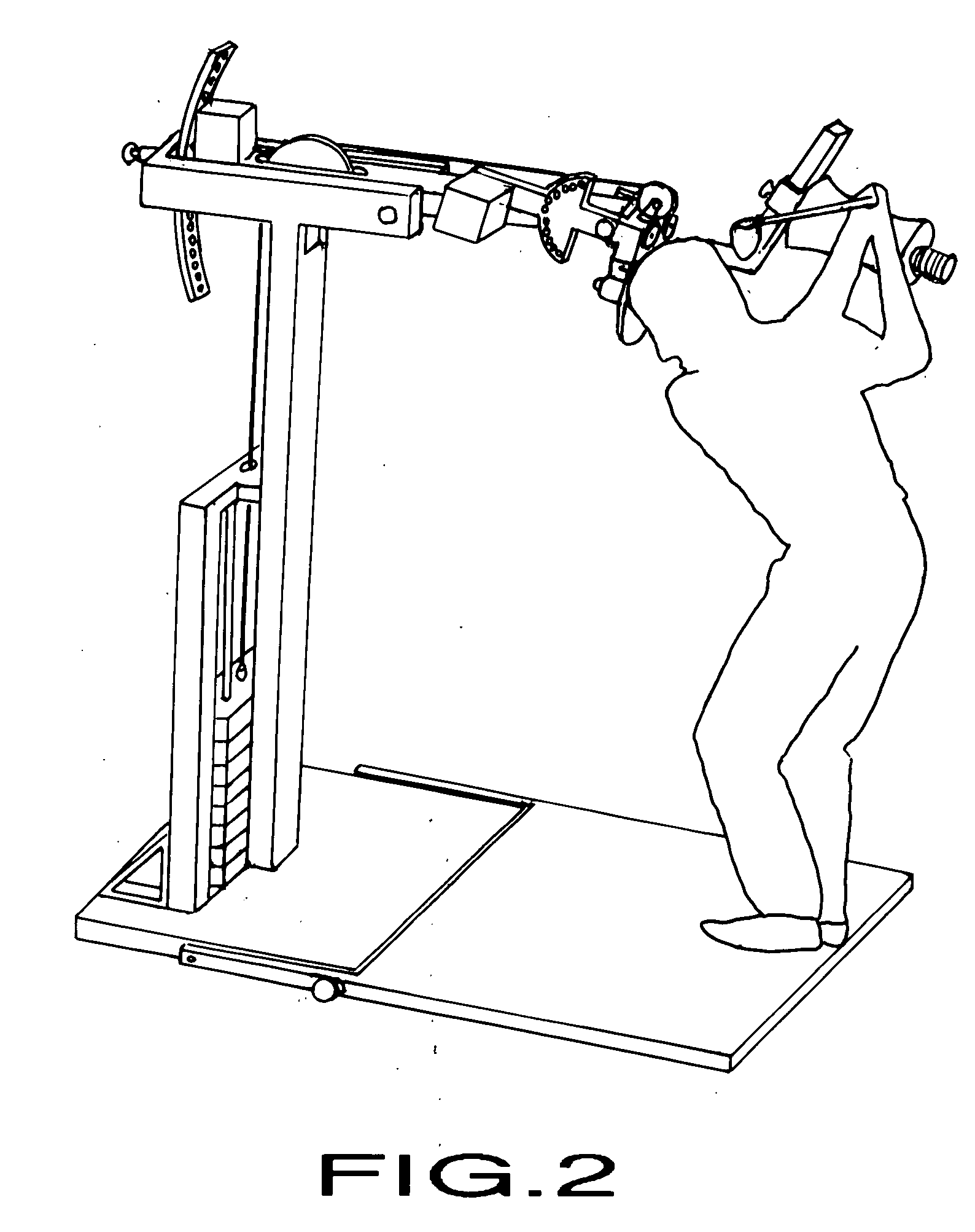

[0245] In the first embodiment, the support arm element 40, best seen in FIGS. 1,3,5 and 15, has an elongated support arm member 45 that is positioned within and extends out from the horizontal frame member 32. The approximate length of support arm member 45 is 2.5 to 4.5 feet. In FIG. 5, a threaded fulcrum bolt 101 crosses the U-opening and connects the engagement holes 108a-b on the two lateral sides 32a-b of horizontal frame member 32. The threaded fulcrum bolt 101 passes through the engagement hole 108a, a nylon thrust washer 102, a fulcrum housing 105 located at the approximate midpoint of the support arm member 45, a nylon thrust washer 106, and through the engagement hole 108b. A lock nut 107 is attached to threaded fulcrum bolt 101 to hold it in position. These components create a hinge 95 that divides support arm member 45 into a proximal support arm half 45a and a distal support arm half 45b. A nylon bushing 103 lines fulcrum housing 105 to assure smooth movement of suppor...

third embodiment

[0248] A third embodiment for support arm element 40 has the distal support arm half 45b angulated downward on proximal support arm half 45a, shown in FIGS. 15c and 16. This downward, angulation positions hinge 95 above the proximal and distal support arm halves 45a-b and makes it easier to balance support arm member 45 on fulcrum bolt 101. This enhanced balance of support arm member 45 on frame element 20 makes the apparatus 90 safer. Also note that in this embodiment, support arm member 45 is composed of two parallel beams that have one or more cross attachments (47a and 47b). The space between the parallel beams of support arm member 45 and cross attachments 47a and 47b makes up pulley opening 41. The placement of pulley unit 205 in this embodiment is in alignment with fulcrum bolt 101 (FIG. 16). Fulcrum bolt 101 acts as the axis of pulley unit 205. Also seen in FIGS. 15c and 16 is the swing plane pin 46 attached to an L-extension 481 extending laterally from the distal support a...

fourth embodiment

[0256] A fourth embodiment for swing plane adjustment element 50 (shown in FIGS. 14c and 17) has a hydraulic unit 401 originating from the distal support arm half 45b and attaching to the uppermost aspect of adjustment lever 56. This hydraulic unit 401 replaces counterweight 52 and makes it easy for the golfer to adjust the swing plane adjustment element 50 into a different swing plane angular position. This embodiment also uses a different swing plane fixation means. Instead of having the semi-circular member 54, there is a short apertured square tubing 411 and a square tube slider 412. Short apertured square tubing 411 is slidable within square tube slider 412. Short apertured square tubing 411 is attached to hinged brackets 42c on the underside of support arm member 45, and square tube slider 412 is attached to hinged brackets 413 that project down from shaft housing 58. Repositioning of swing plane adjustment element 50 by the exercising golfer causes short apertured square tubi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com