Garbage Bin Descending Control System

a control system and garbage bin technology, applied in the field of garbage bin descending control system, can solve the problems of bin damage, comparatively higher noise level, and both lid panels will rapidly descend, and achieve the effect of prolonging the service life of the bin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

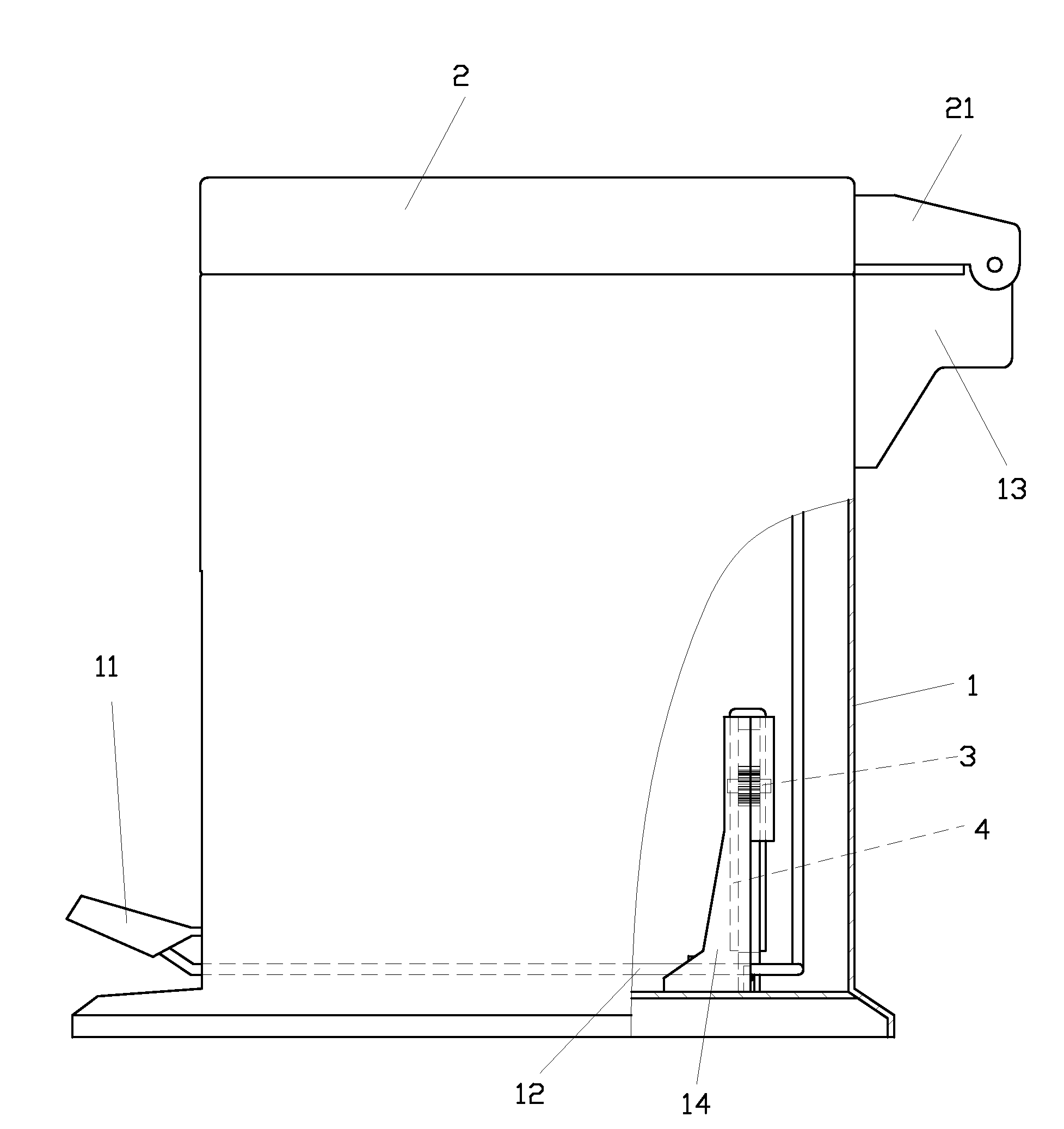

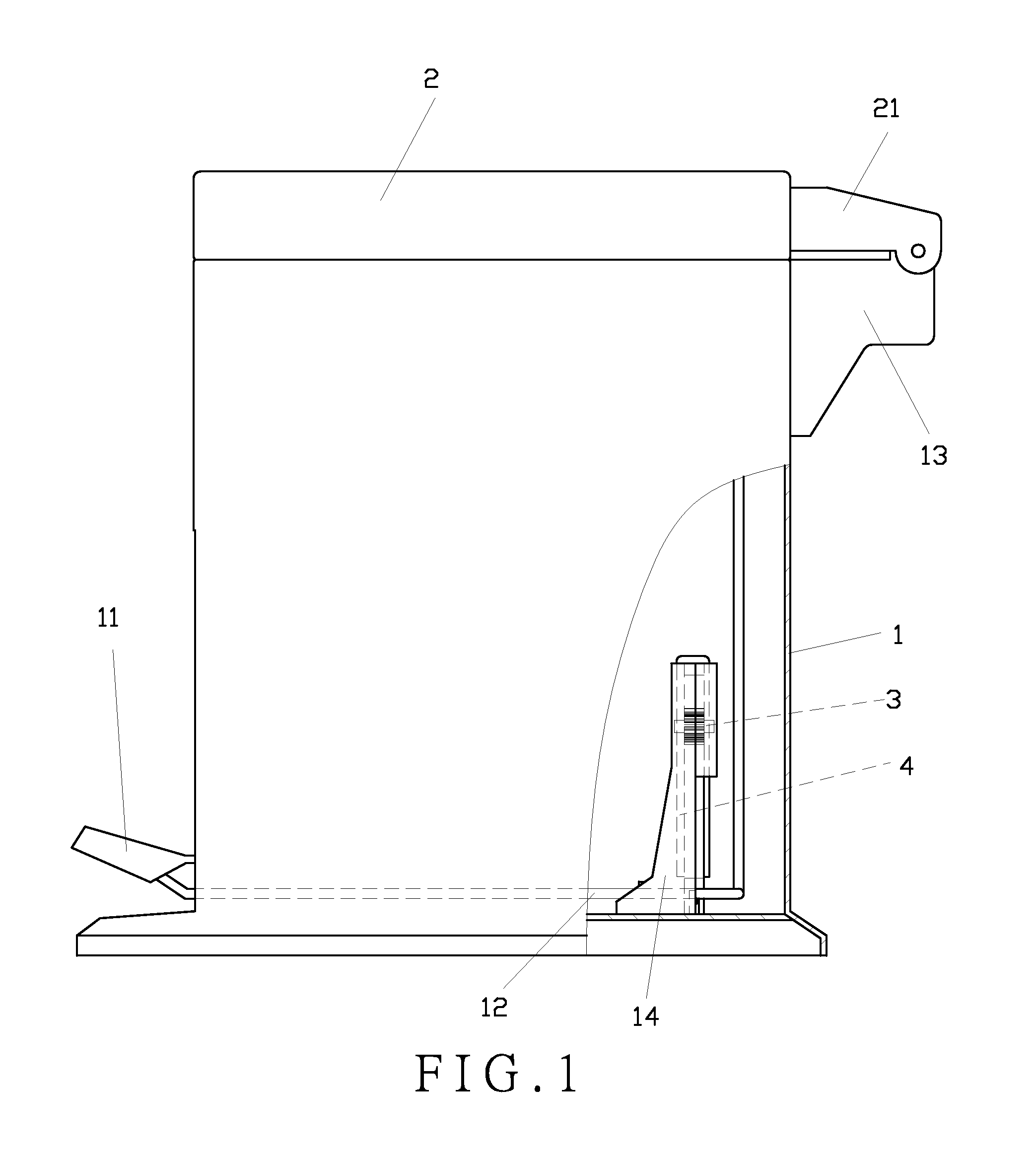

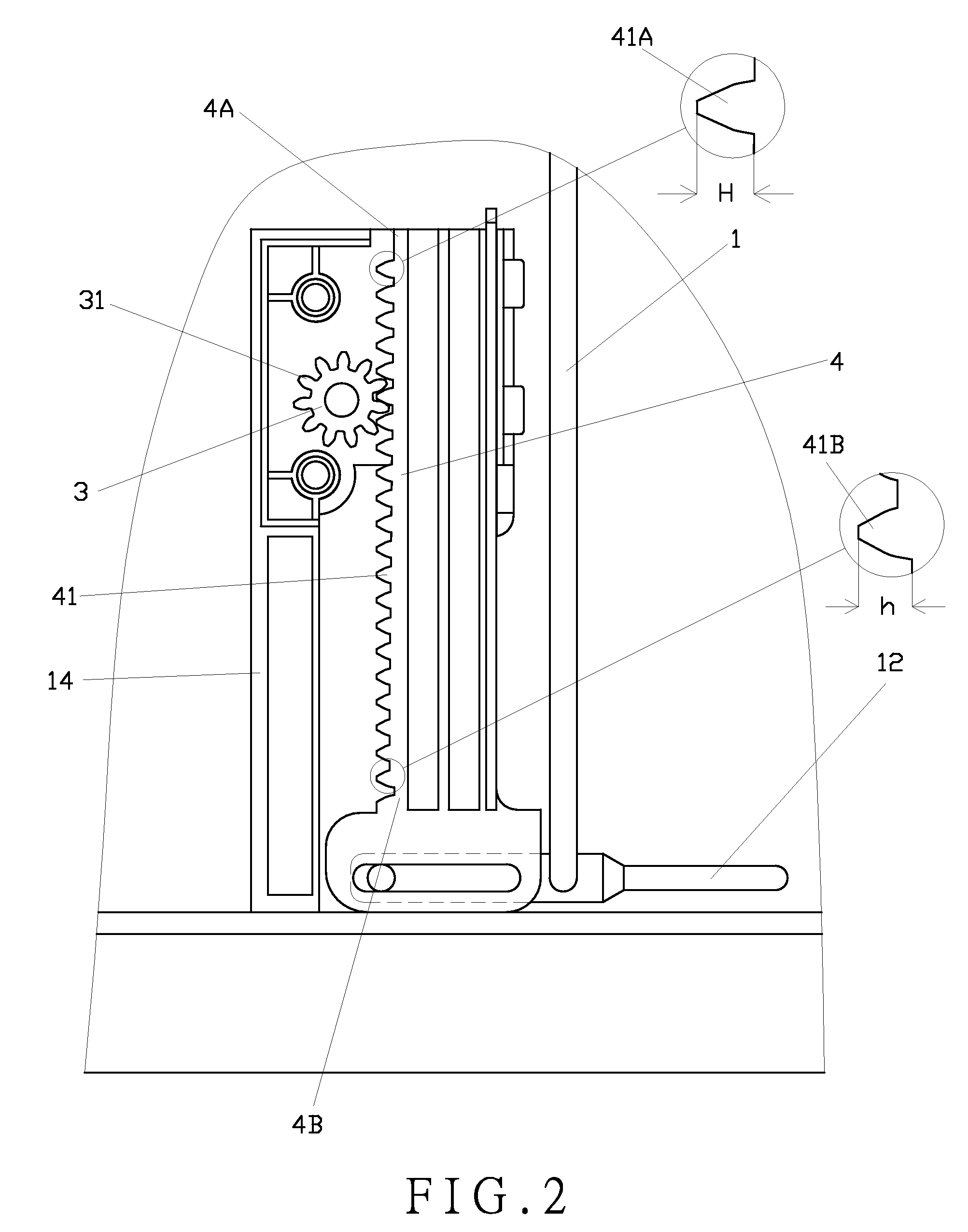

[0024]Referring to FIGS. 1 and 2, a first preferred embodiment of the present invention related to a garbage bin with a single lid comprises of a bin (1), a lid (2), a gear (3) and a rack (4).

[0025]A pedal (11) is externally disposed at a lower end of the bin (1). The pedal (11) controls ascending and descending of an active rod (12) (related to the prior art and will not be illustrated and elaborated herein). A pivoting portion (13) is disposed at an upper end of the bin (1). A locating base (14) is provided on the bottom in the bin (1).

[0026]The lid (2) pivoted to the pivoting portion (13) of the bin (1) opens up or closes up when pushed up by the active rod (12). The lid (2) is provided with a pivoting end (21) to be pivoted to the pivoting portion (13) of the bin (1).

[0027]The gear (3) secured in the locating base (14) of the bin (1) is annularly disposed with multiple teeth (31).

[0028]The rack (4) secured in the locating base (14) of the bin (1) is a straight rack to engage wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com