Heatable ice perforation device

a perforation device and perforation technology, which is applied in the field of heat dissipation devices, can solve the problem that the device does not have gasoline engine problems, and achieve the effect of reducing the number of perforation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

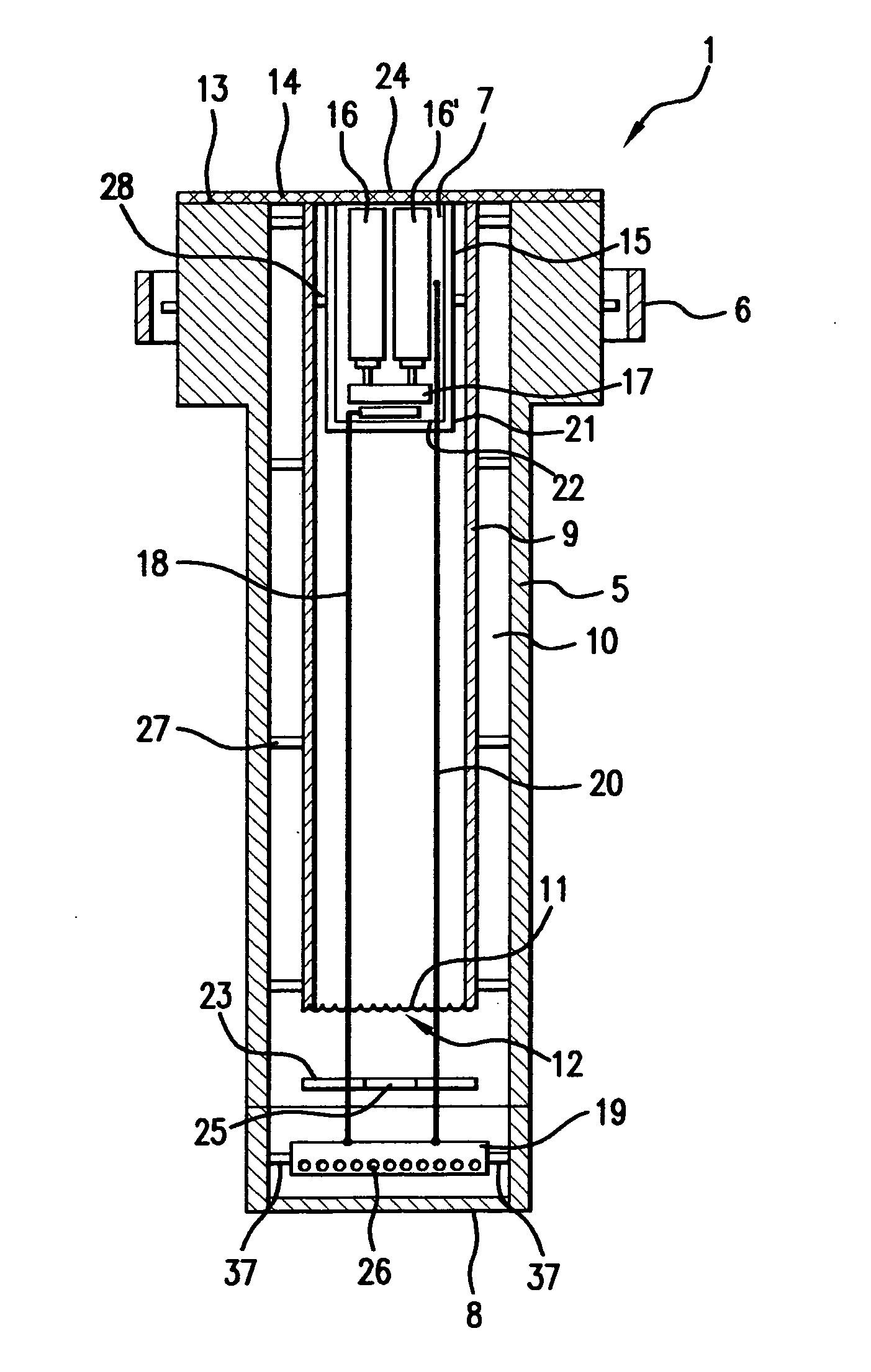

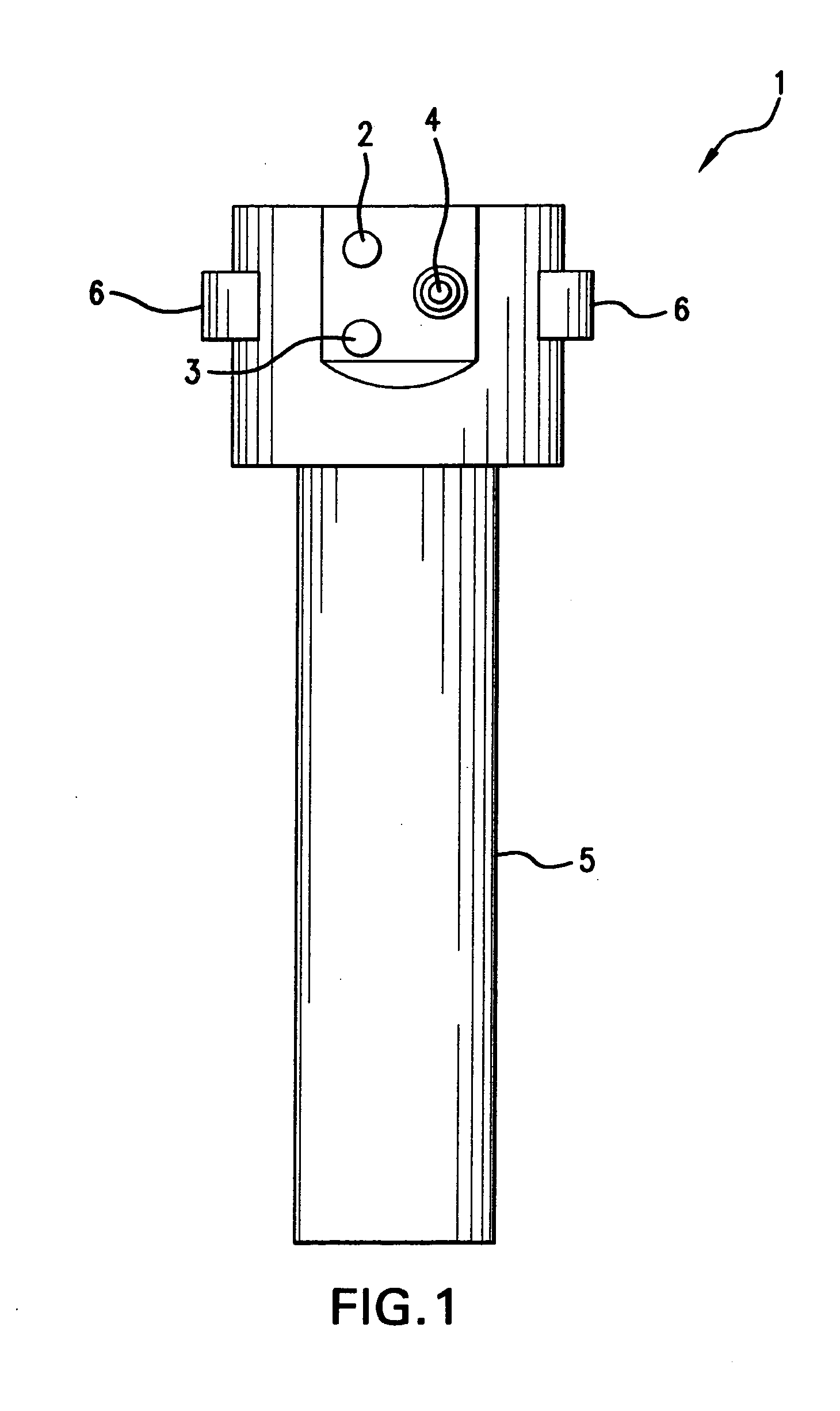

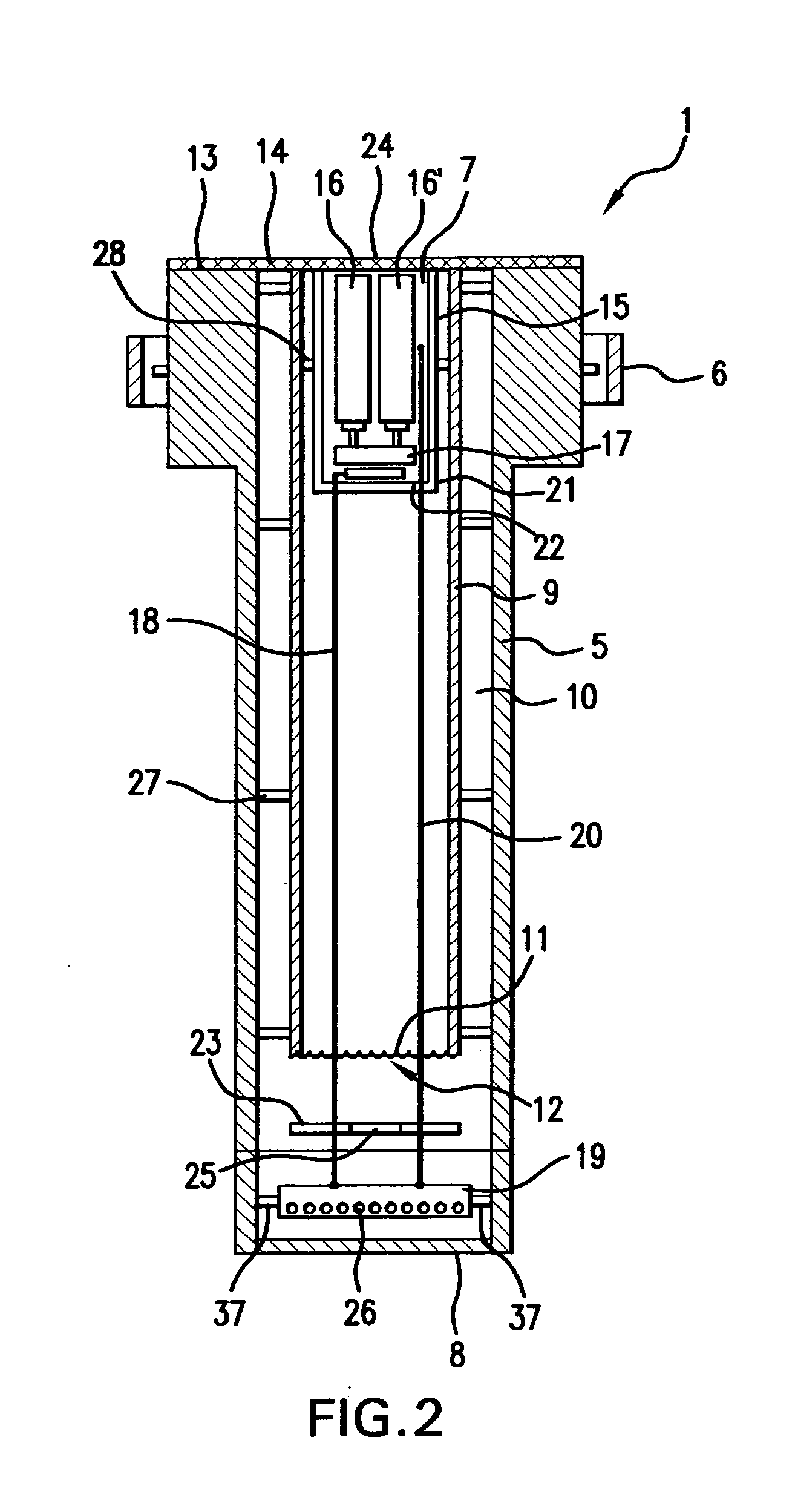

[0028] Turning now to FIG. 1, and for purposes of describing and illustrating the invention disclosed herein, there is shown a full side view of an ice penetration device 1 that is equipped with gas tanks (FIG. 2) as the energy source. In FIG. 1, there is shown an on / off valve 2 for the gas (also shown in FIG. 4), and an on / off valve 3 for the gas burner, along with a push button igniter 4 for igniting the gas (also shown in FIG. 4), all contained in the wall of the outside housing 5.

[0029] The overall size of the devices of this invention may be from about 24 inches to about 48 inches in height and about 6 to fourteen inches in diameter, it being understood that the devices do not have to circular, as they may be square, rectangular, triangular, and the like.

[0030] In FIG. 1, there is shown a gas on / off valve 2 and a burner on / off valve 3, along with a push button igniter 4 for igniting the gas the utility of which and the interaction of which will be discussed with reference to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com