Anchor Element For Knotless Fixing Of Tissue To A Bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

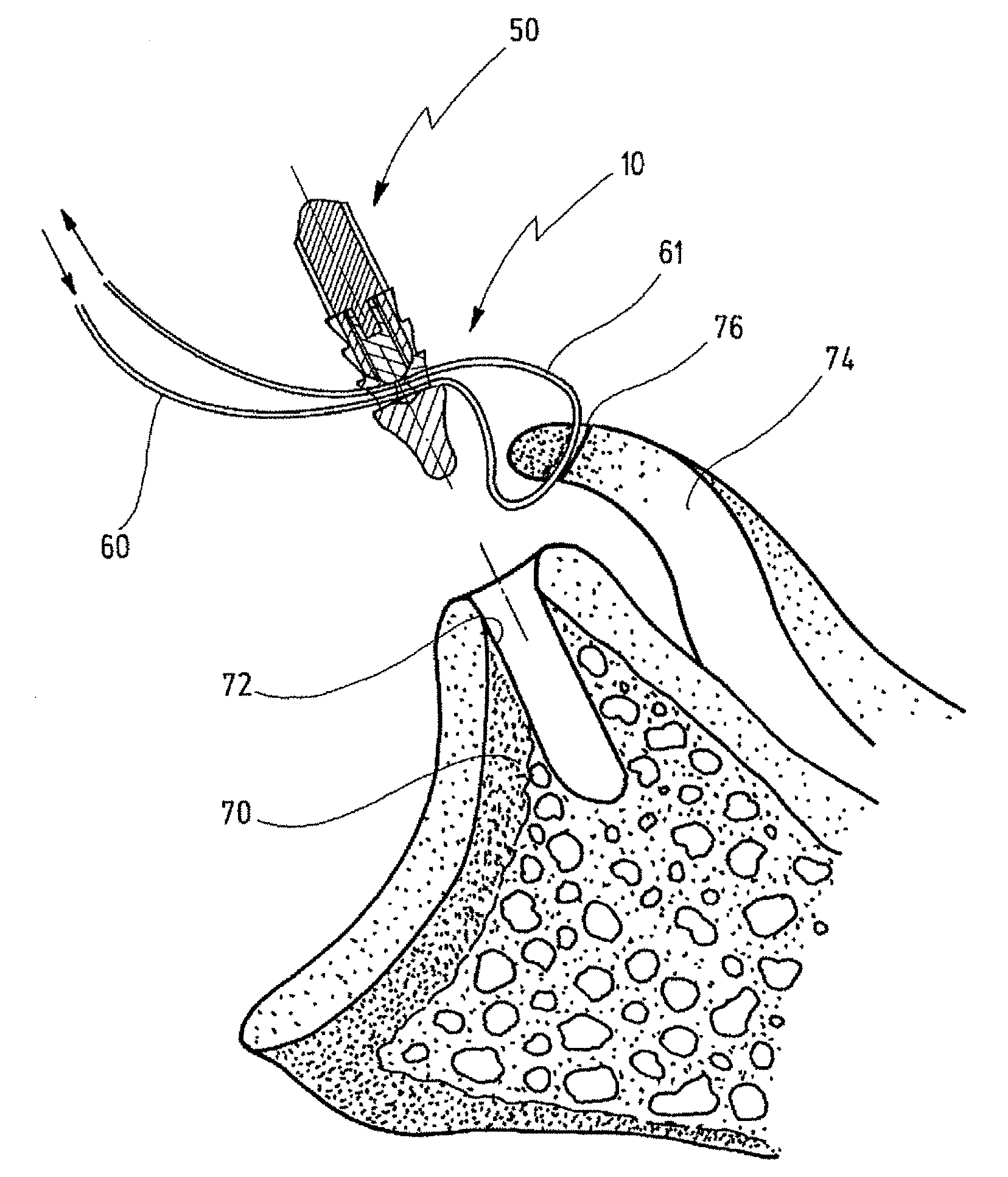

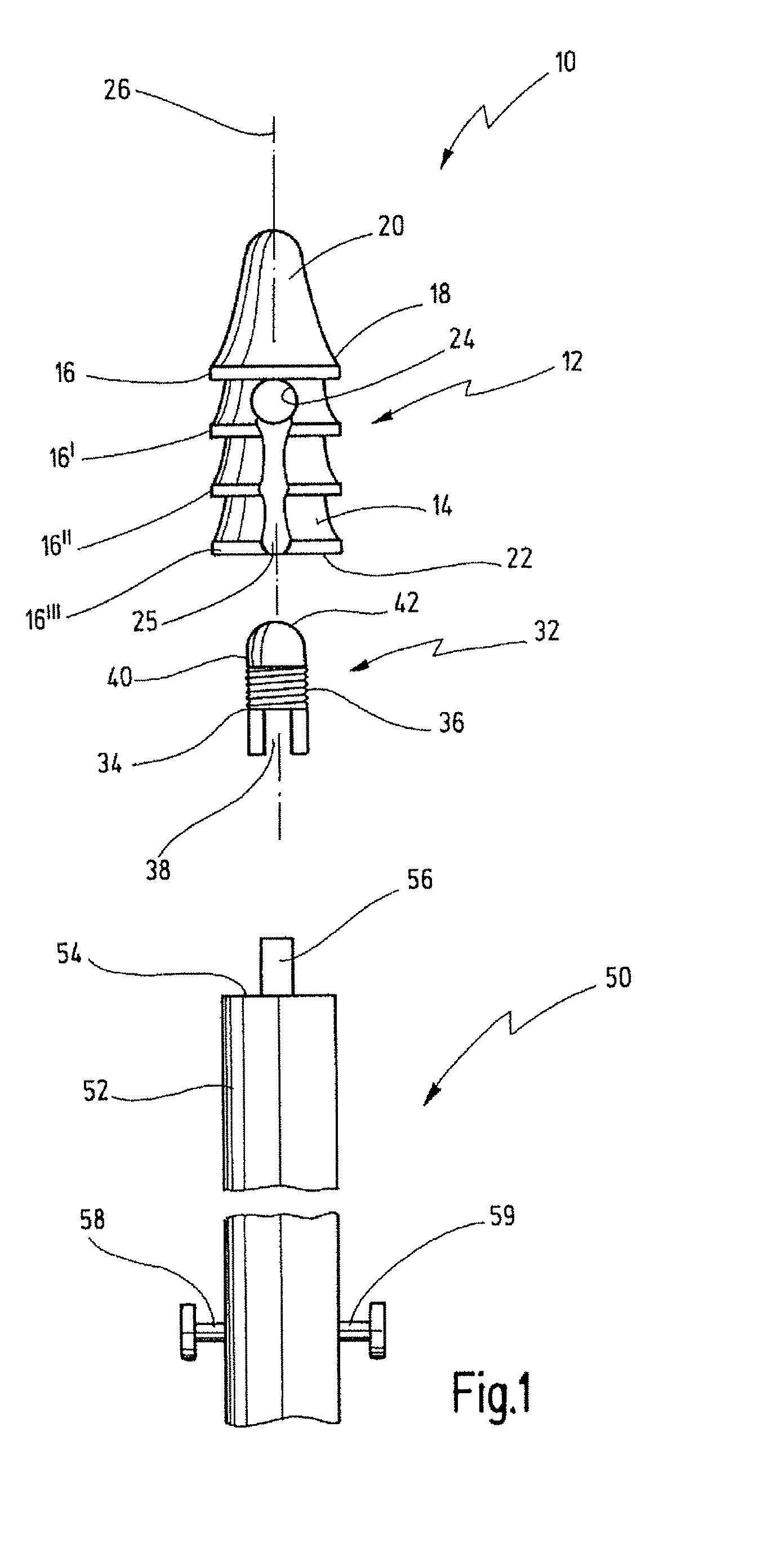

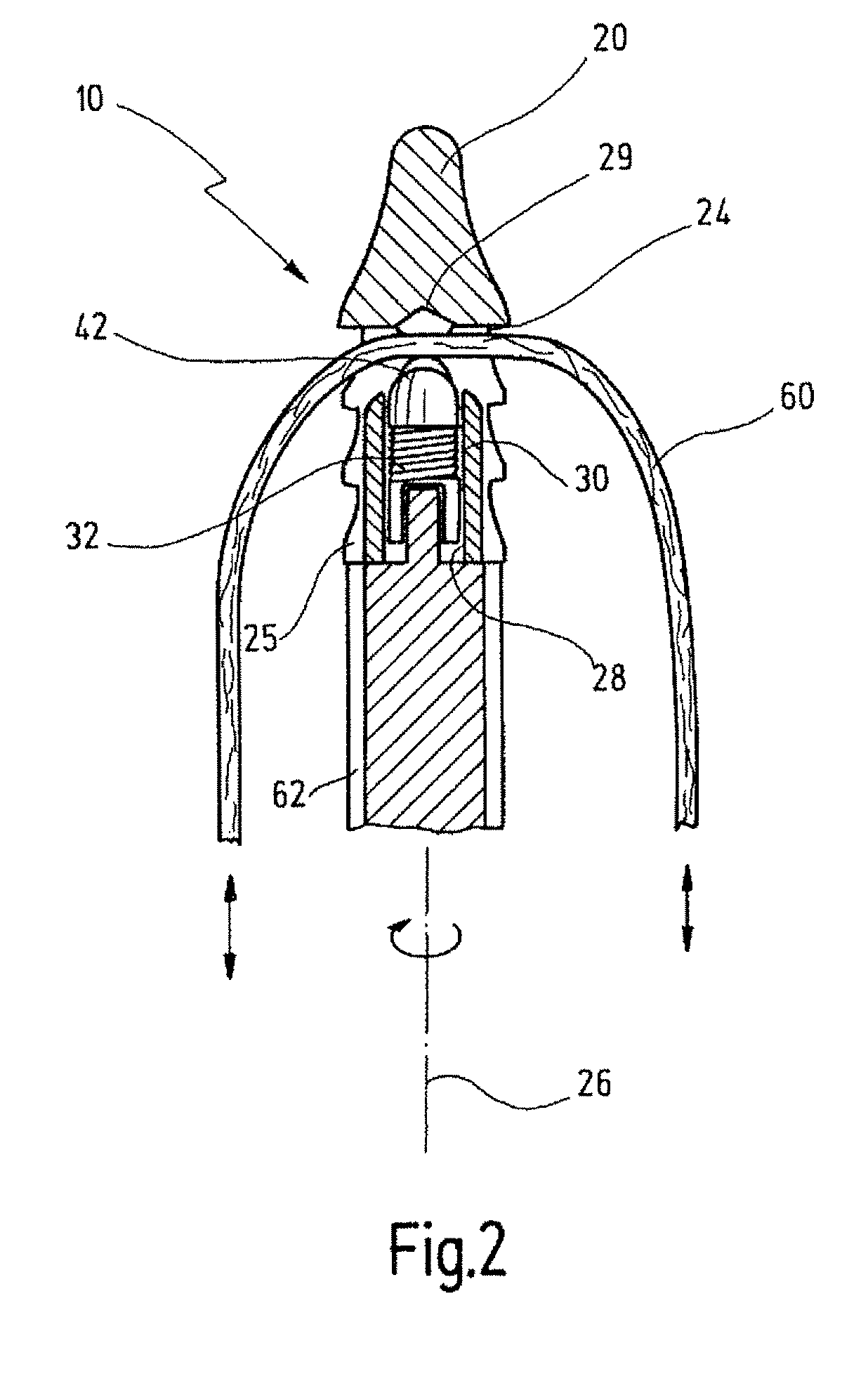

[0056] An anchor element shown in FIGS. 1 to 4 is designated in its entirety by reference number 10.

[0057] The anchor element 10 has an elongate, roughly cylindrical body 12 from whose outer face 14 a number of projections 16 to 16′″ protrude. The projections 16 to 16′″ are designed as protruding annular flanges which, viewed in the distal direction, each merge with the next annular flange via approximately conically tapering portions. A distal end area 18 of the body 12 is provided with a rounded tip 20. A proximal end 22 is formed by the cross-sectional surface area of the last projection 16′″.

[0058] In the distal end area 18 of the body 12, a transverse bore 24 is arranged extending through the latter. Starting from the mouth of the transverse bore 24, two diametrically opposite longitudinal grooves 25, cut into the projections 16′ to 16′″, extend proximally along the longitudinal axis 26 of the body 12.

[0059] The transverse bore is used for threading a suture 60 through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com