Implant for osteosynthesis

a technology for implants and osteosynthesis, applied in the field of implants for osteosynthesis, to achieve the effect of preventing postoperative bone screw migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

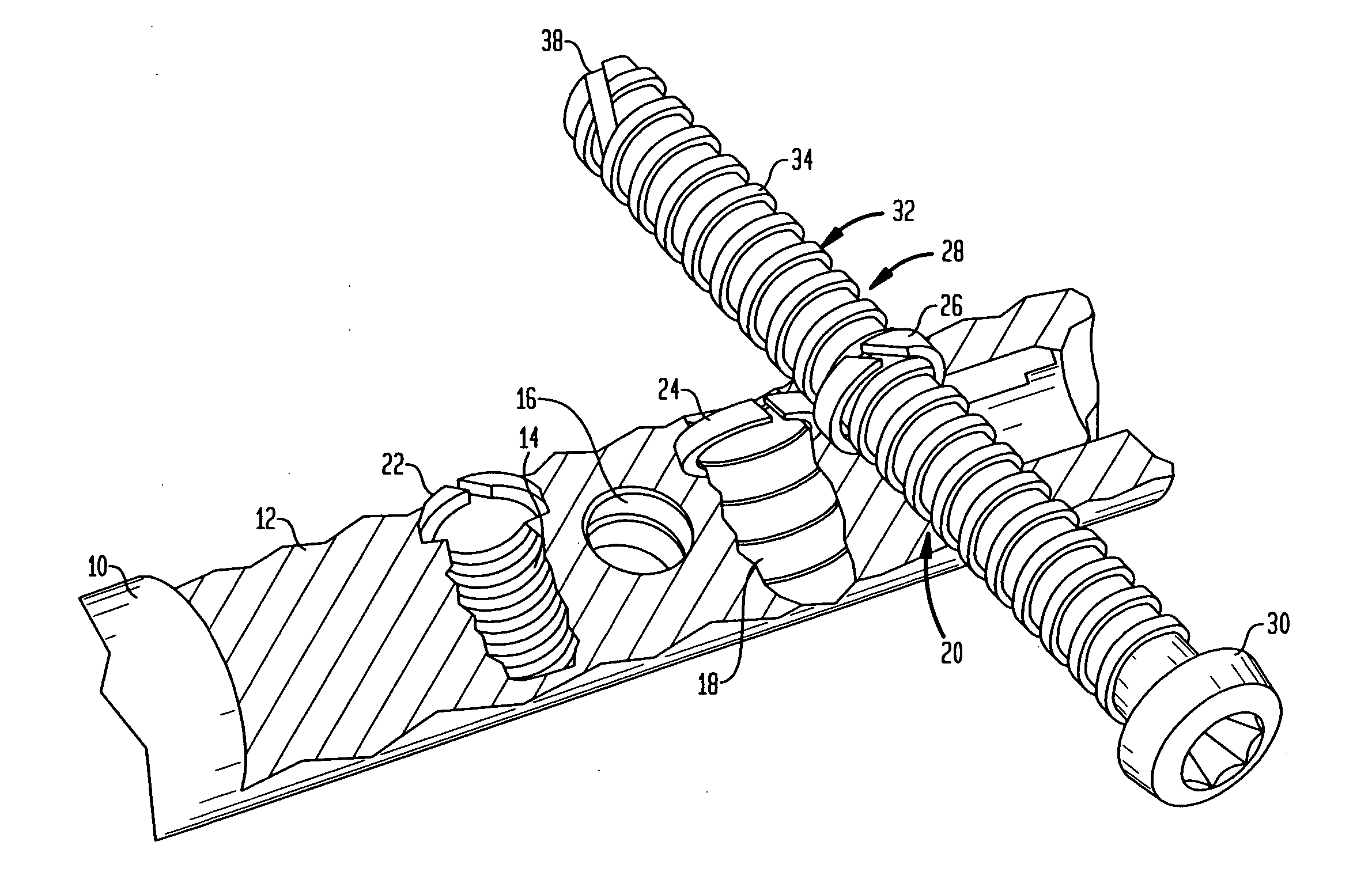

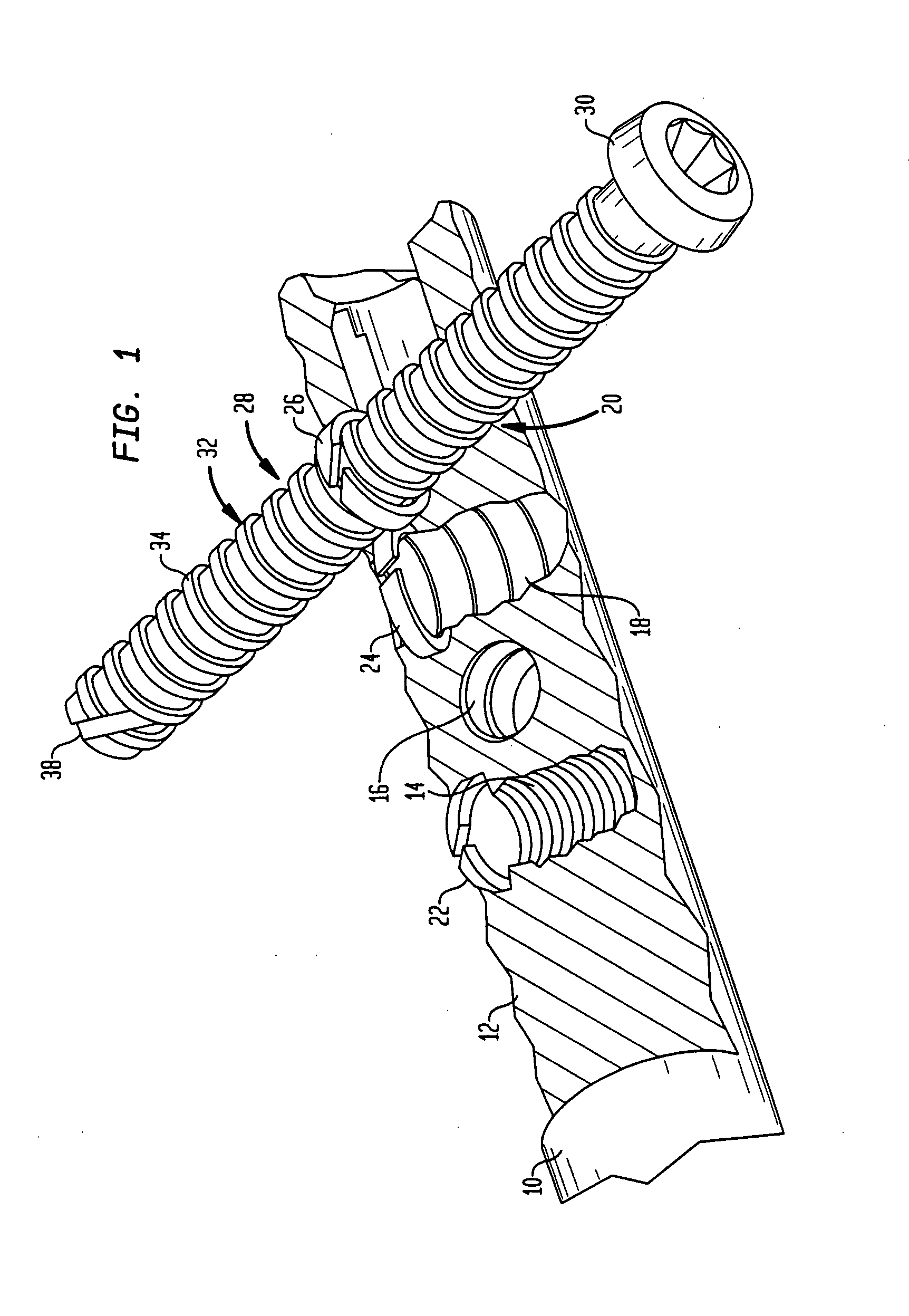

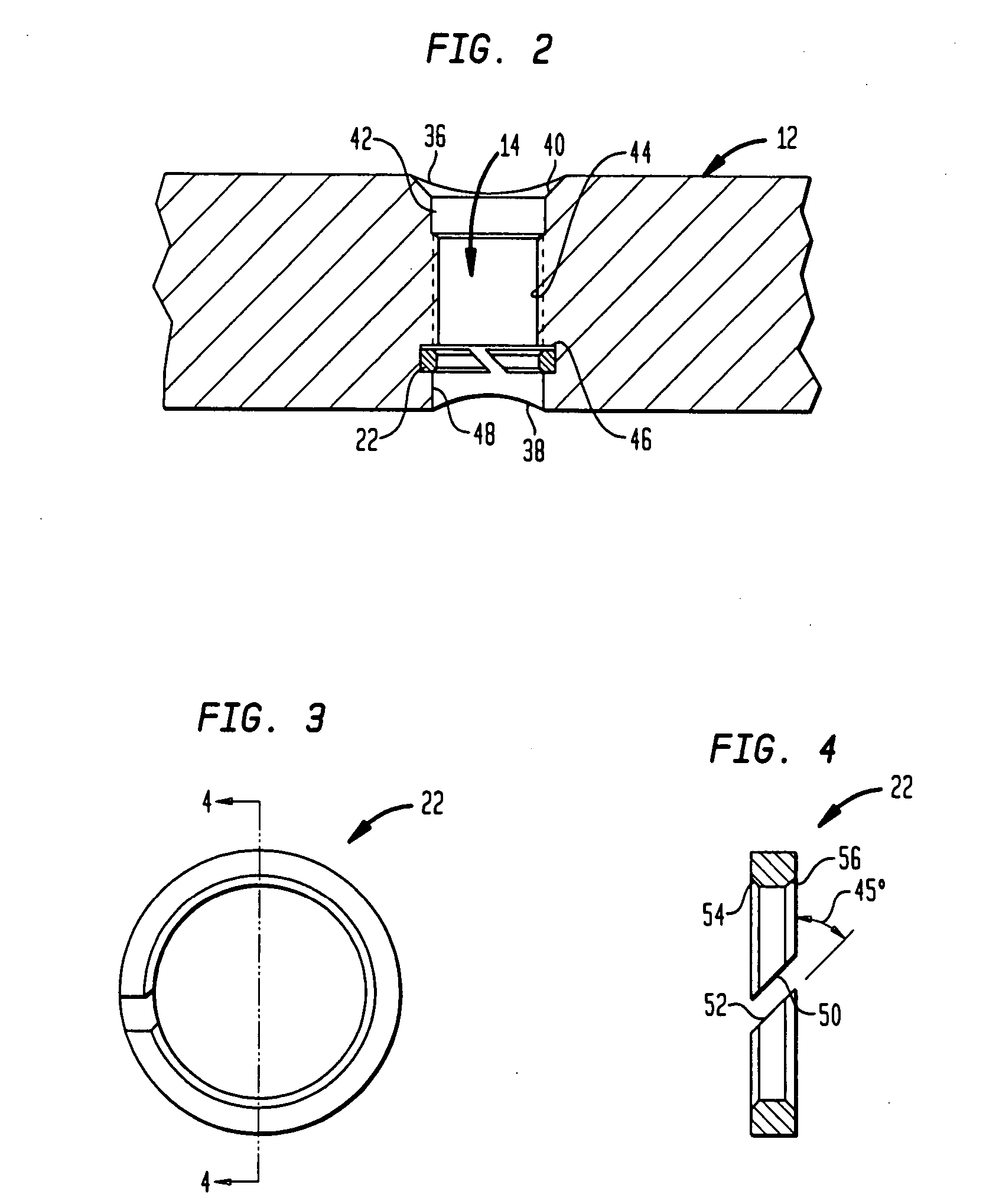

[0018] Referring to FIG. 1 there is shown a humeral nail 10 having four offset cross-bores and having a longitudinally sectioned proximal portion 12. As can be seen, the preferred proximal portion 12 is provided with four cross-bores 14, 16, 18 and 20 which, in the preferred embodiment are offset from each other in the axial and circumferential directions and are at an angle from the longitudinal axis 21 of nail 10. In the preferred embodiment, bores 14, 16, 18 and 20 are configured as threaded bores. FIG. 1 further shows that bores 14, 18 and 20 receive a securing ring 22, 24 and 26, respectively. If desired, bore 16 can also include a securing ring. These rings serve for securing an interlocking screw 28 which has a head 30 and a shank 32 with thread 34. In the preferred embodiment thread 34 is a cortical thread which is useful in ensuring a fixed seating in the bone without unnecessarily imposing a stress on the bone. The preferred thread 34 is a flat thread which threadably enga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com