Backflow Preventer

a backflow preventer and flue technology, applied in the field of flue backflow preventers, can solve the problems of increasing the size or volume of the device as it is installed, increasing the cost of design, installation, maintenance, and inconvenience, and achieve the effect of reducing the backflow in the pressure zon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

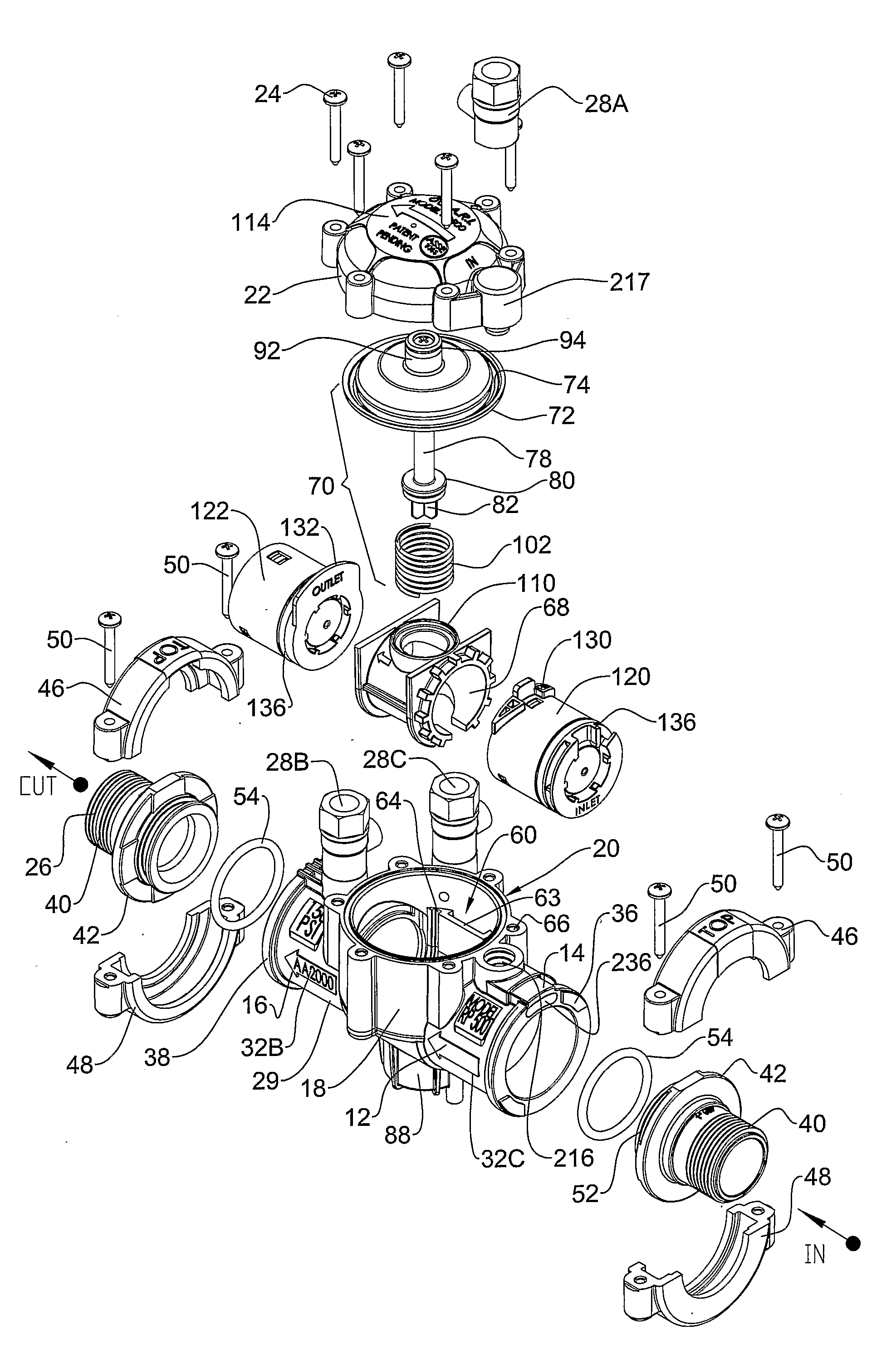

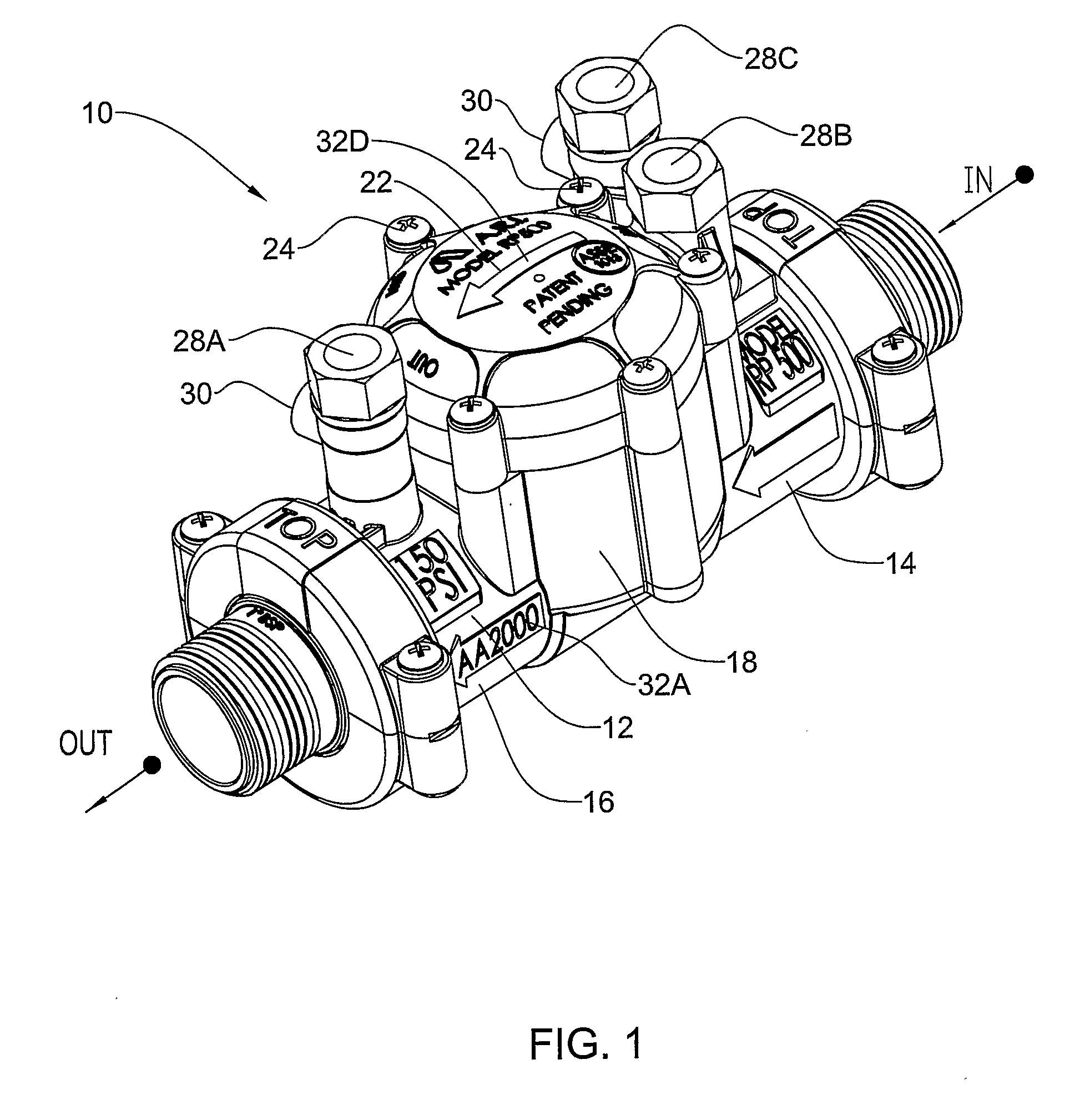

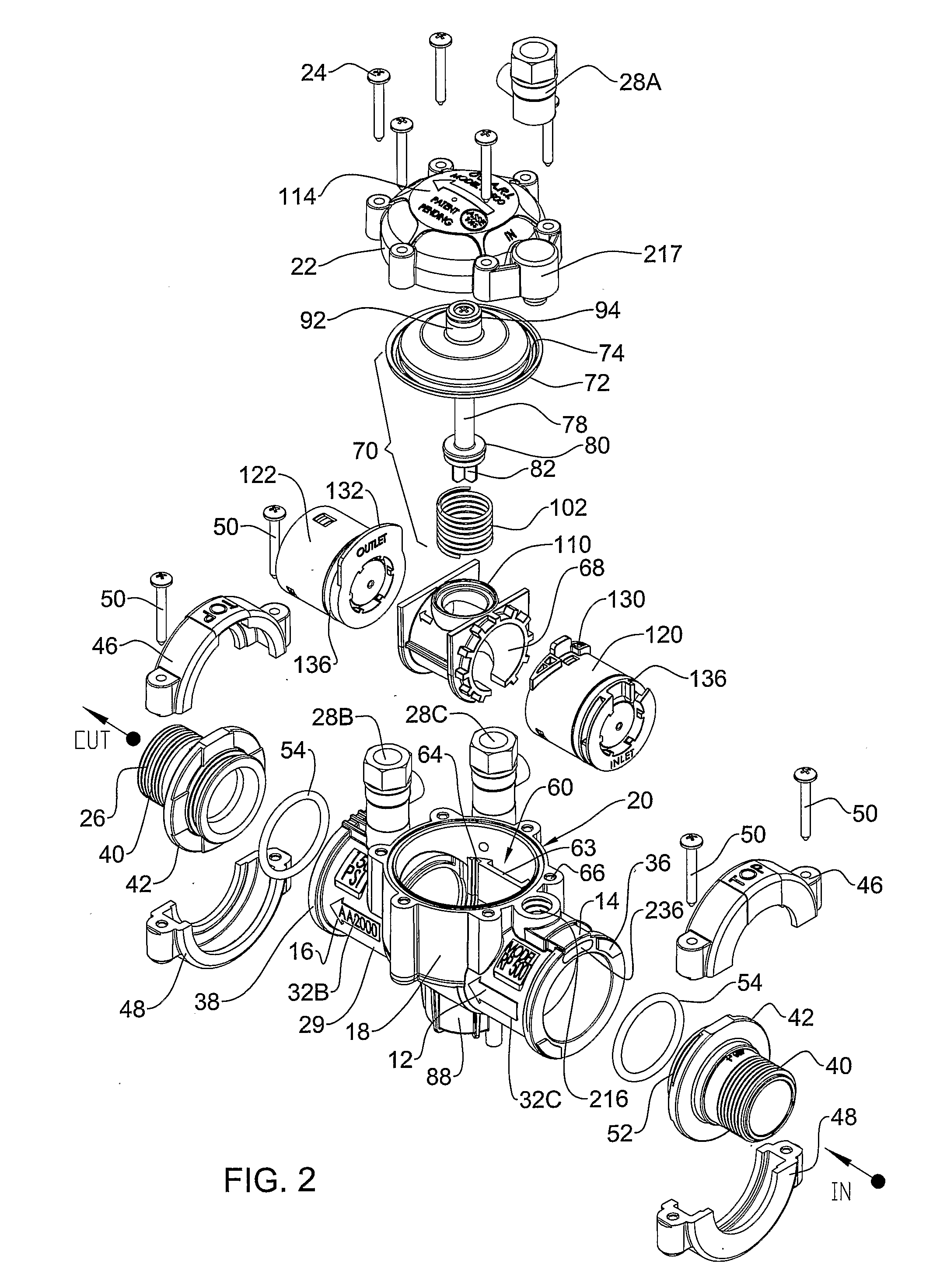

[0054] Attention is first directed to FIG. 1 of the drawings for general familiarization with the backflow preventer device according to the present invention, formed with an elongate cylindric body 12 made of rigid plastic material extending between an inlet end with an inlet port 14 and an outlet end with an outlet port 16, coaxially aligned. The body is a uniform rigid solid structure made of plastic material, optionally of composite material for reinforcement thereof.

[0055] The body 12 further comprises an upright extending cylindrical portion 18 extending at a right angle with respect to the longitudinal axis of the body 12 and formed with an opening (29 in FIG. 2) sealingly covered by a cover 22 fixedly secured in place by a plurality of screws 24.

[0056] Three test cocks 28A (being in flow communication with the inlet port through aperture 59; see FIG. 3A), 28B (being in flow communication with the central space 60 through aperture 61; see FIG. 3A) and 28C (being in flow com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com