Shoulder support for garment hangers

a technology for garment hangers and shoulders, applied in the field of shoulders and hangers, can solve the problems of garments being soiled, damaged, unfit for sale, inadvertently dislodged from their respective hangers, etc., and achieve the effect of enhancing the retention system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

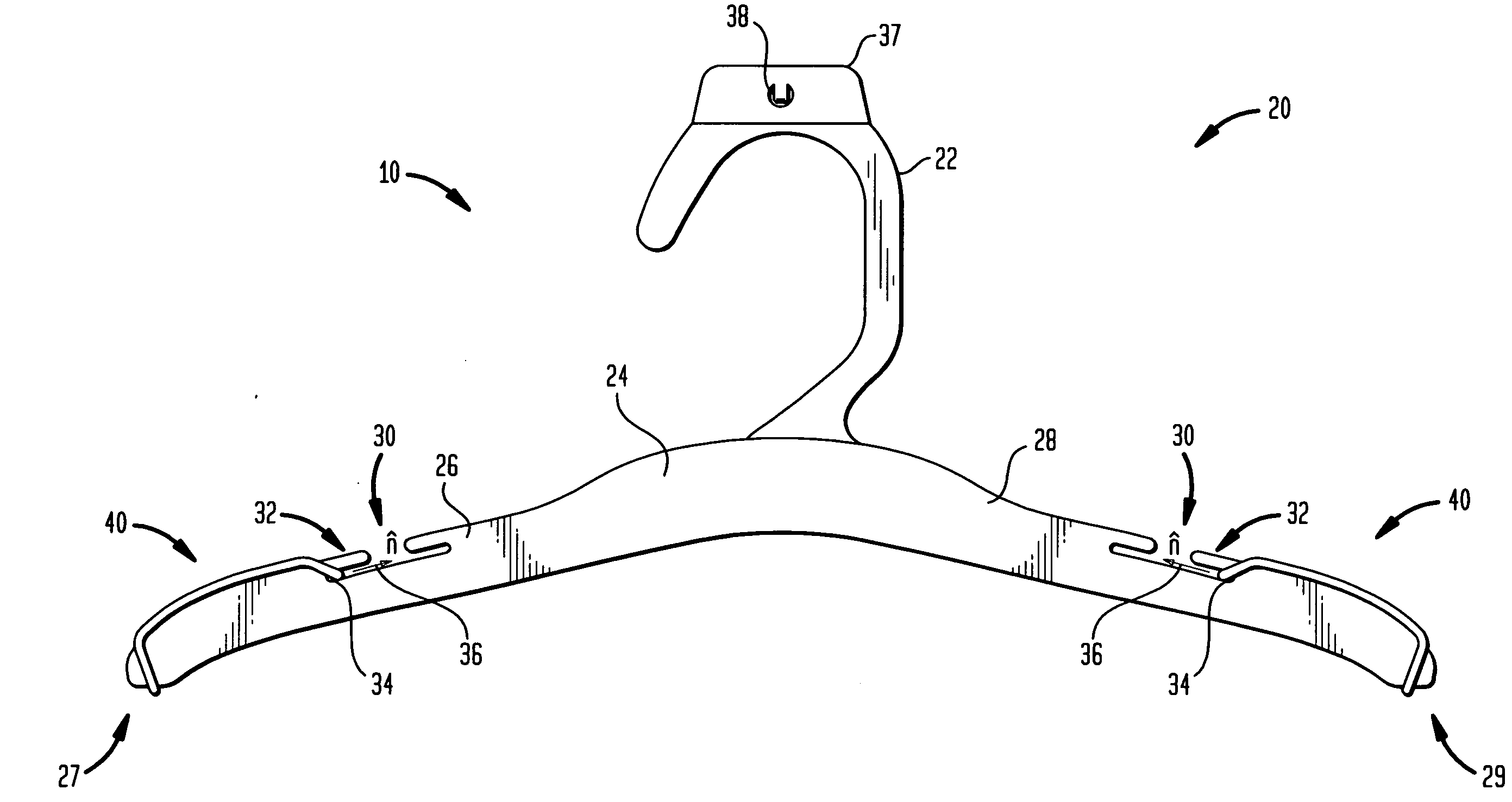

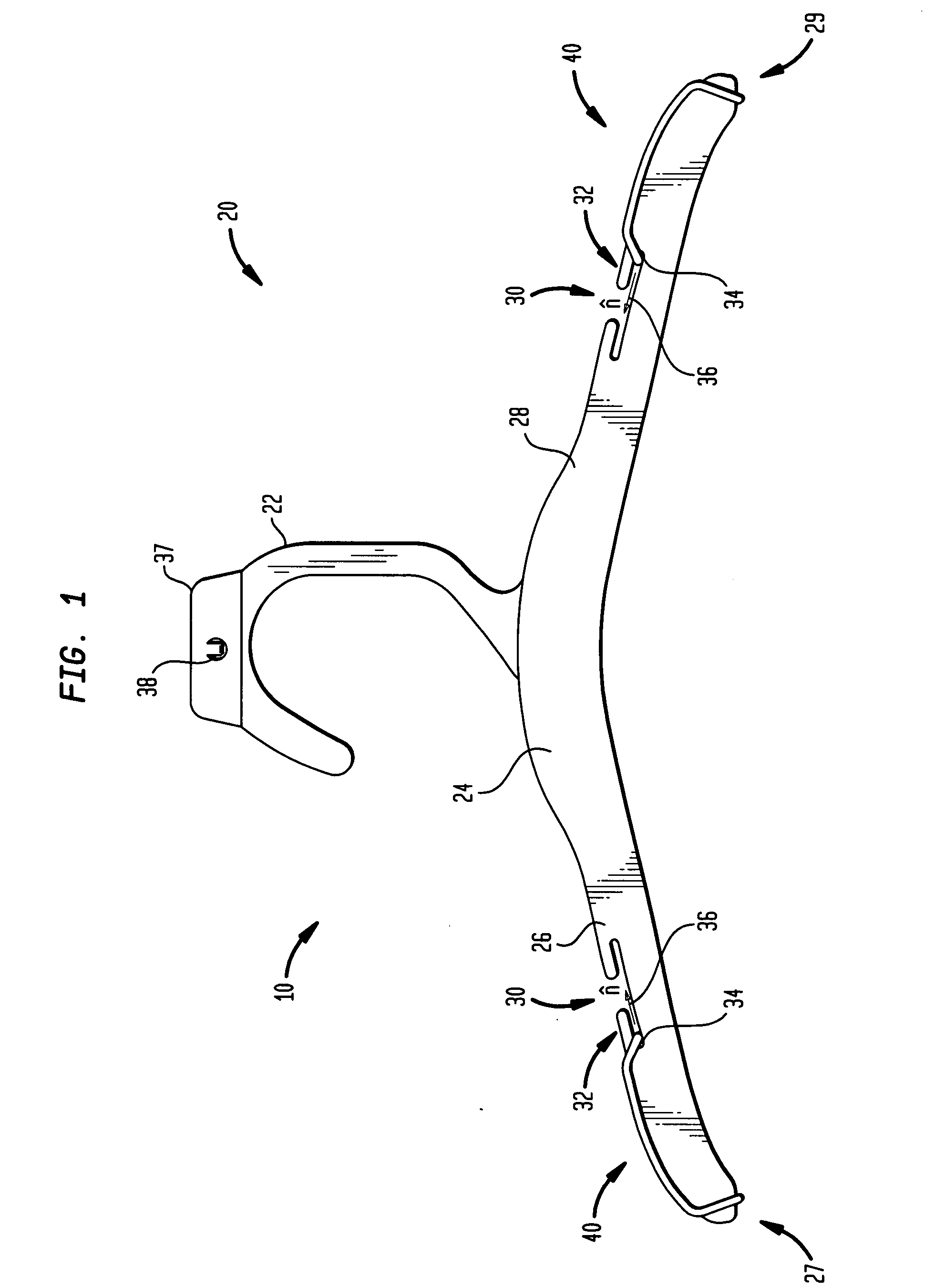

[0014] Referring now to FIG. 1, illustrated is a front plan view of a garment retention system, generally 10, according to an exemplary embodiment of the present invention. Retention system 10 includes at least a garment hanger 20 and an attachment portion 40. Garment hanger 20 may be a conventional hanger for garment tops, including at least a hook 22 for suspending the hanger 20 from a support, and a body 24 having two arms 26, 28 laterally extending away from the body 24 to respective distal ends 27, 29. Arms 26, 28 may be sloped downward from the body, enhancing the need for improved retention characteristics, though this is not necessary to the present invention.

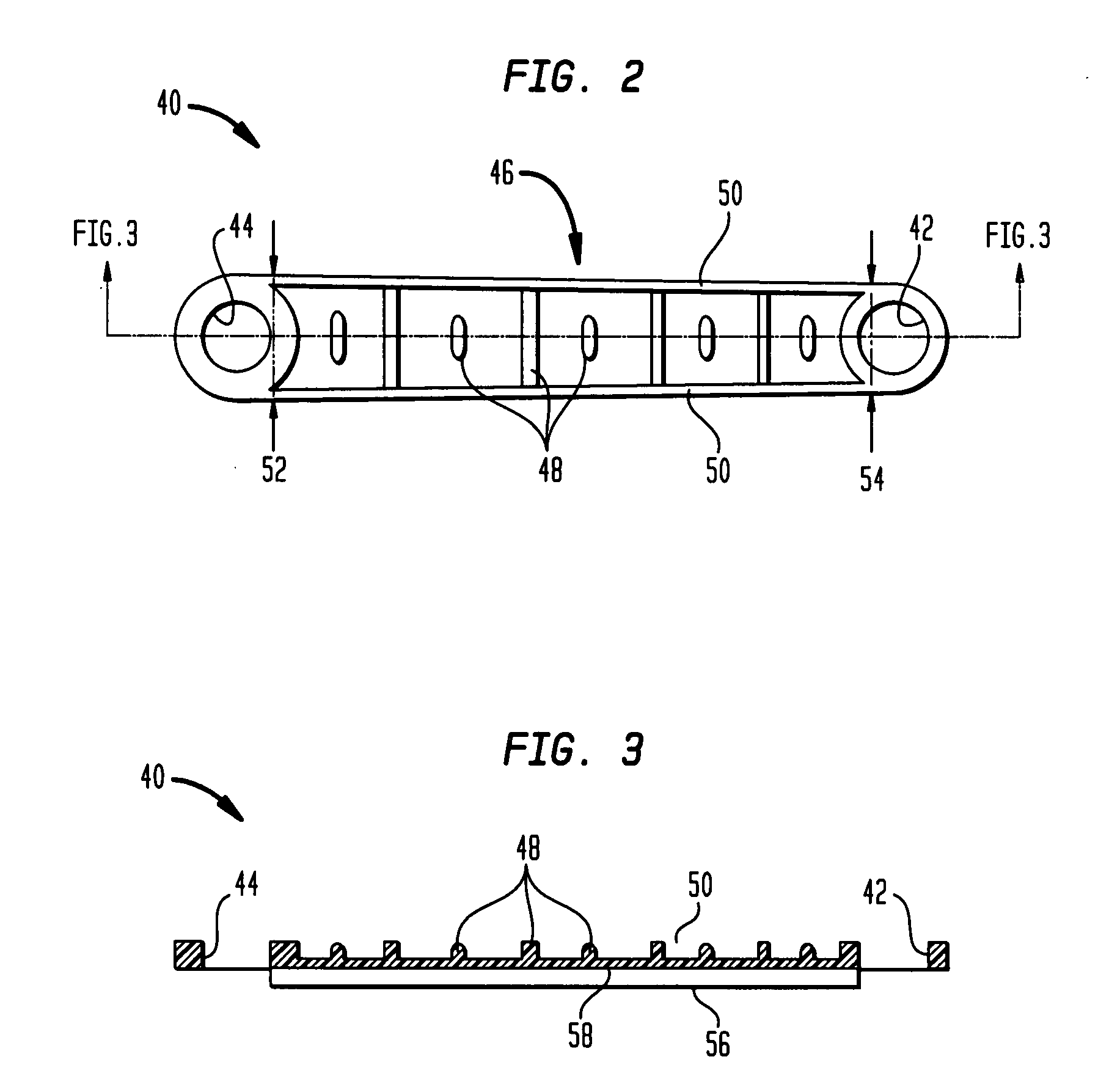

[0015] Each of arms 26, 28 includes a recess 30 in an upwardly facing surface, and may include some overhang 32 at least partly covering the recess 30, and extending proximally towards the body 24 from a distal side of the recess 30. More generally, each arm 26, 28 presents an attachment retention surface 34 having a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com