Core drill assembly with adjustable total flow area and restricted flow between outer and inner barrel assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

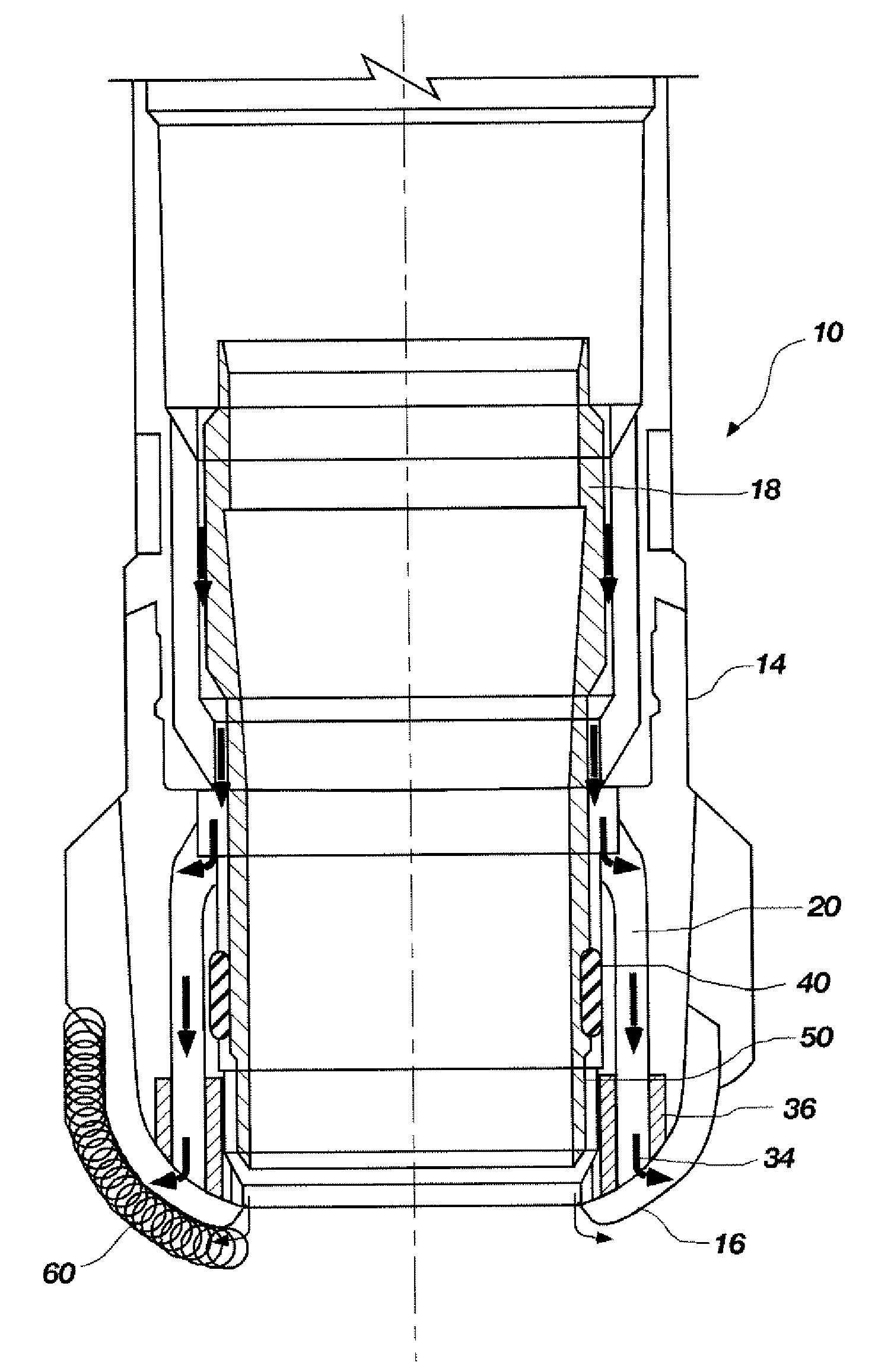

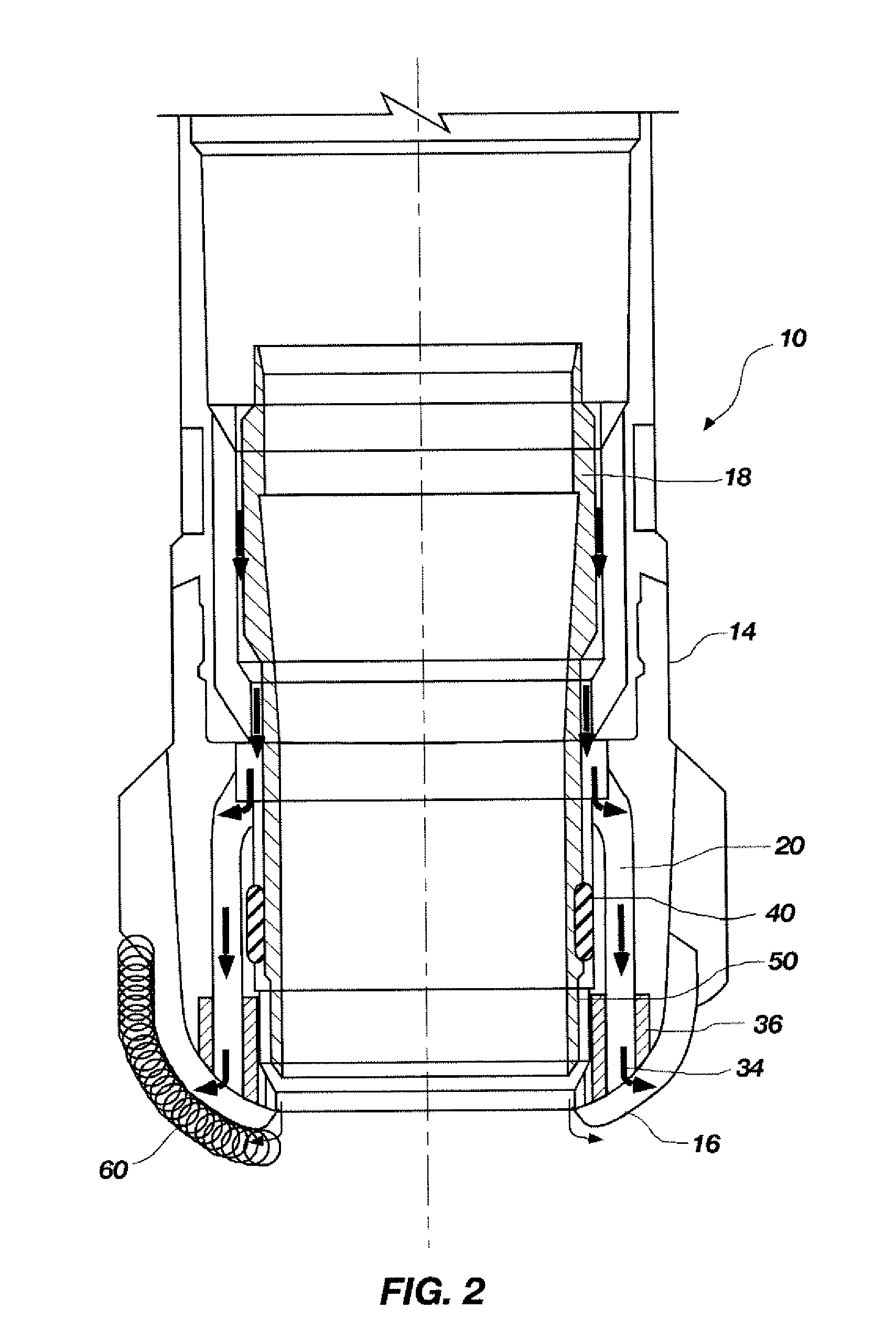

[0021]FIG. 2 schematically depicts a core drill assembly 10 of the present invention including replaceable nozzles 36 at the discharge ends of fluid courses 20, and at least one seal assembly 40 disposed between the core head 14 and the lower shoe 18. These features allow the operator to change the TFA of the core drill assembly 10 and optimize the HSI. The operator can select replaceable nozzles 36 having a discharge opening 34 of an appropriate diameter to adjust TFA. Thus, if a volume of drilling fluid is pumped under pressure, at a substantially constant flow rate, down the drill string, seal assembly 40 will divert substantially all of the drilling fluid volume away from the annulus 50 and into the fluid courses 20 where the drilling fluid will exit through discharge opening 34 of replaceable nozzles 36. The diameters of discharge openings 34 will affect both the rate of discharge and the velocity of the escaping drilling fluid. Under optimized conditions, as provided by the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap