Firearm barrel vibrational stabilizing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

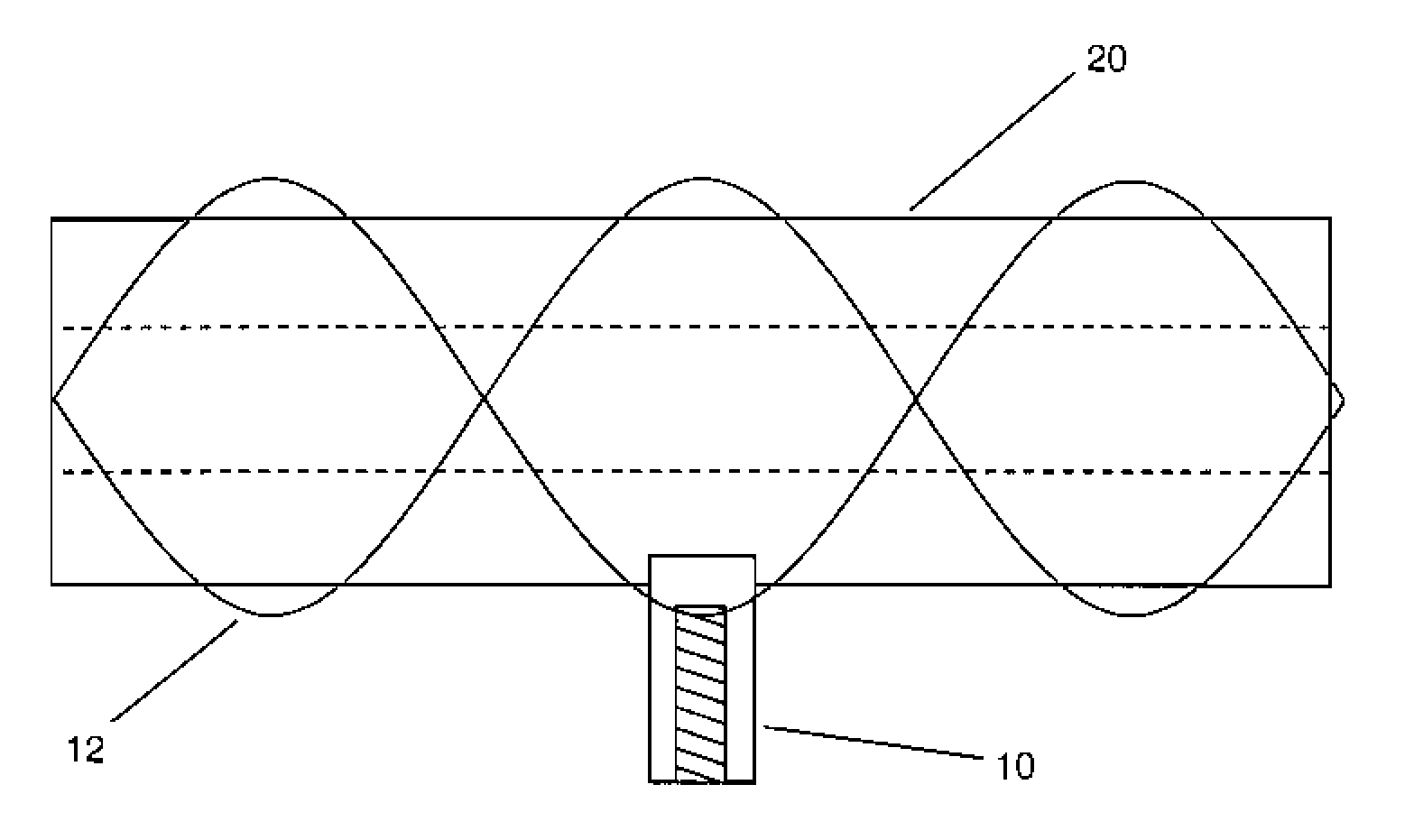

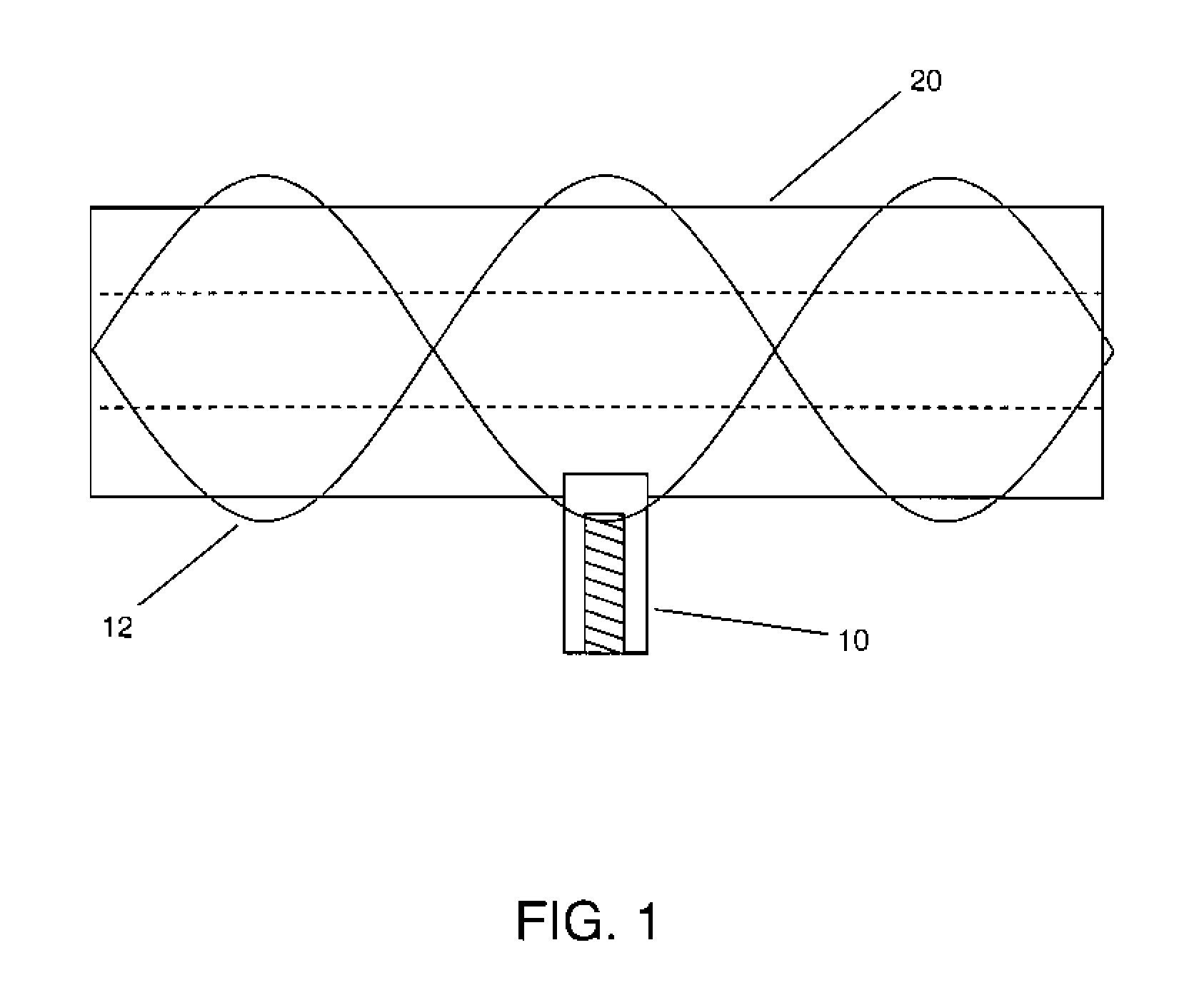

Image

Examples

example 1

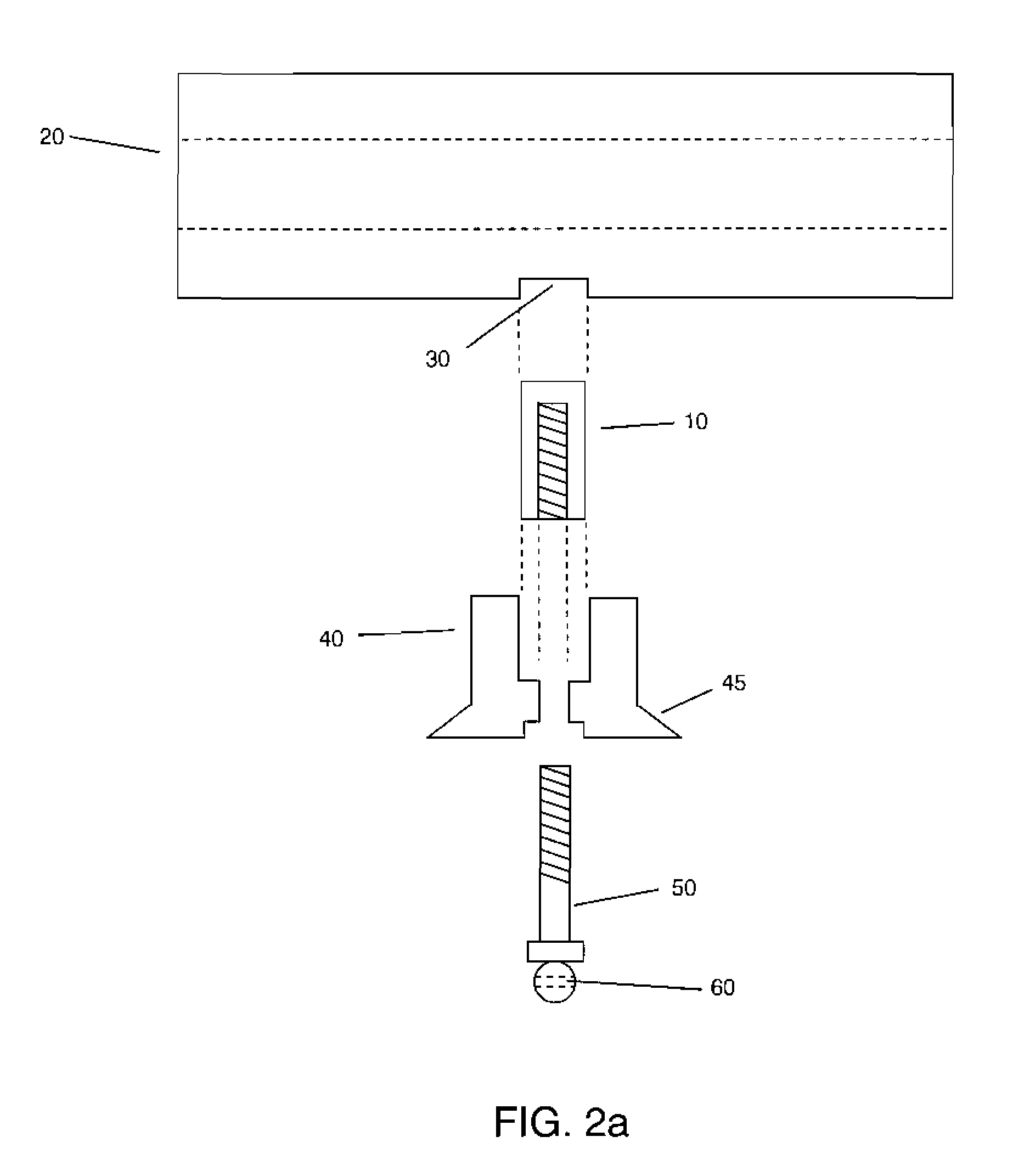

[0027]A .256 Newton custom 98 Mauser rifle equipped with the vibrational stability device of the present invention was test fired by a shooting and ballistics expert using a variety of ammunition at various loads. Referring to FIG. 2a, recess 30 was located 8.50″ from the muzzle. Post 10 was 0.375″ in diameter and 500″ long, and comprised a 0.185″ diameter hole with 10-32 TPI threads. Female escutcheon 40 was 9 / 16″ high, comprised a 1¼×¾″ diamond-shaped top as shown in FIG. 2b, and comprised edge 45 which comprised a 6° bevel and was 0.25″ high. Swivel hole 60 was 0.145″ in diameter. Testing showed that there were effectively no signs of high pressure due to the installation of the device, with a maximum case head expansion of 0.002 and only one instance of slightly sticky bolt lift. Bullets of various weights and loads shot monotonously to the same place. Ten shots were fired into two inches using 85, 100, 129, and 140 grain weight bullets in five loads; all but two of the shots fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com