Impact collapsible non-rigid lap tray with four surrounding high sides

a non-rigid, lap tray technology, applied in the direction of bedside tables, furniture parts, domestic applications, etc., can solve the problems of less access when needed, awkward storage of rigid tray, safety hazards in automobiles, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

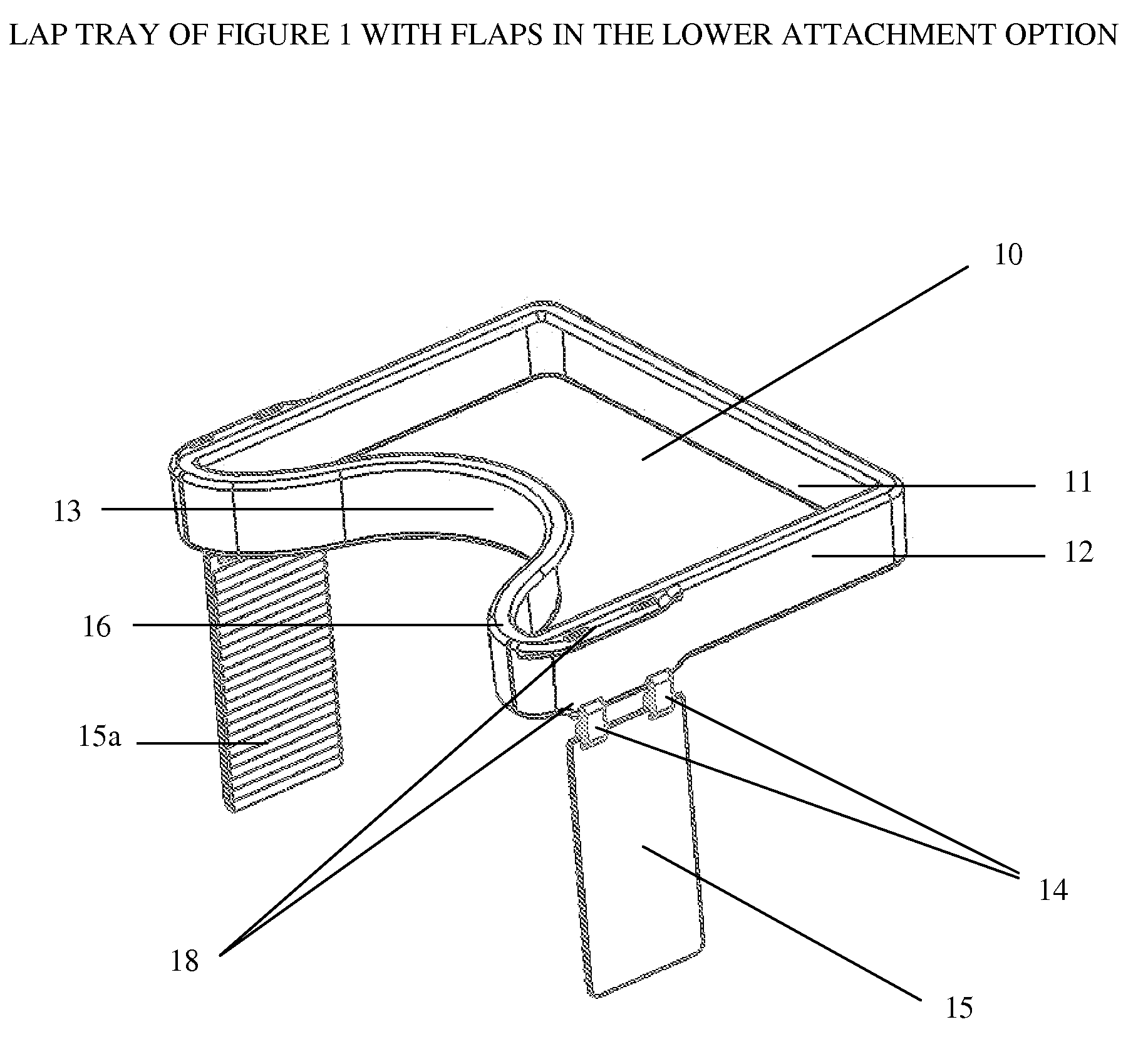

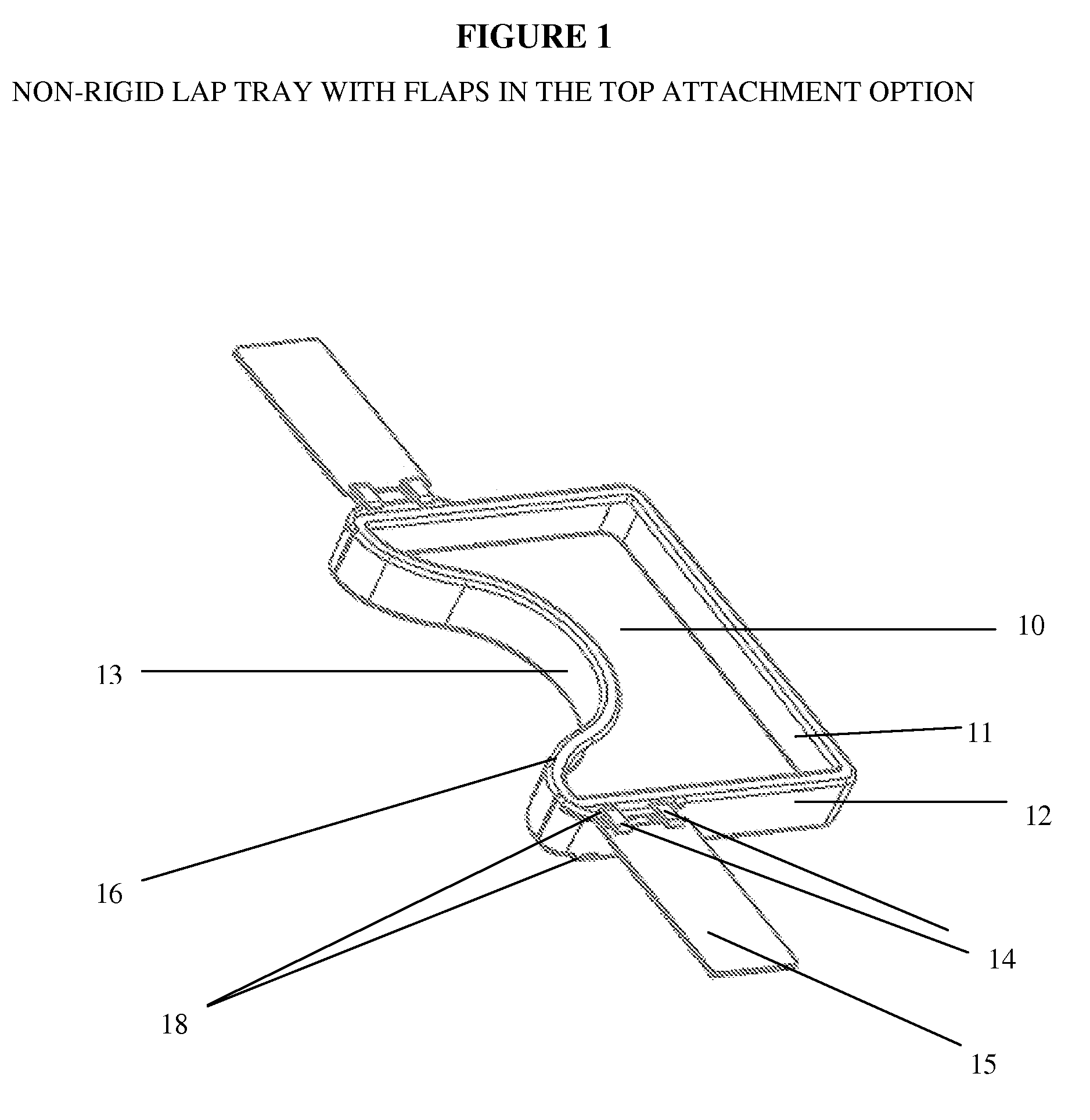

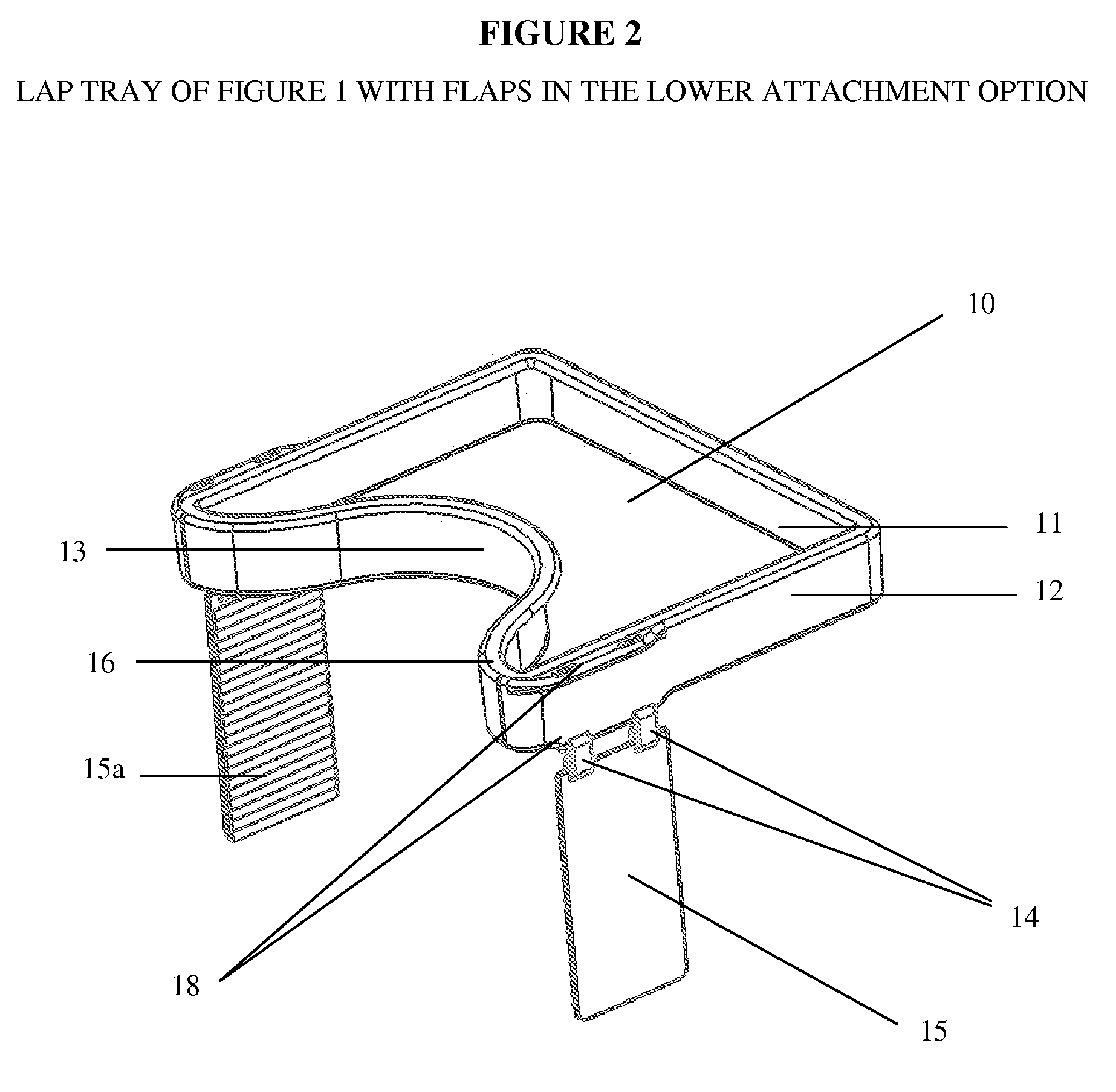

[0016]The preferred embodiment in this invention for the lap tray is to use a silicone material, the method comprising the steps of: providing the lap tray with a bottom base, side walls extending upwardly generally at right angles from the bottom base, each side wall having a peripheral inwardly projecting or outwardly projecting flange, with side walls encapsulating the base. The lap tray is a generally rectangular shape and departs from this form at the rear side of the base where the walls form a semicircular inset into the rear side. The lap tray is made with stabilizing flaps (FIGS. 1-4, 15) having two attachment options in the lap tray for children, and fixed flaps in the lap tray for general use. The stabilizing flaps for children have a series of half-circle rows on one side to add weight and flexibility. The flaps are designed to travel straight out over a car seat or booster seat arm, and then flop downward. On the underside of the lap tray as seen in FIG. 4, base 10a, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com