Selective plating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

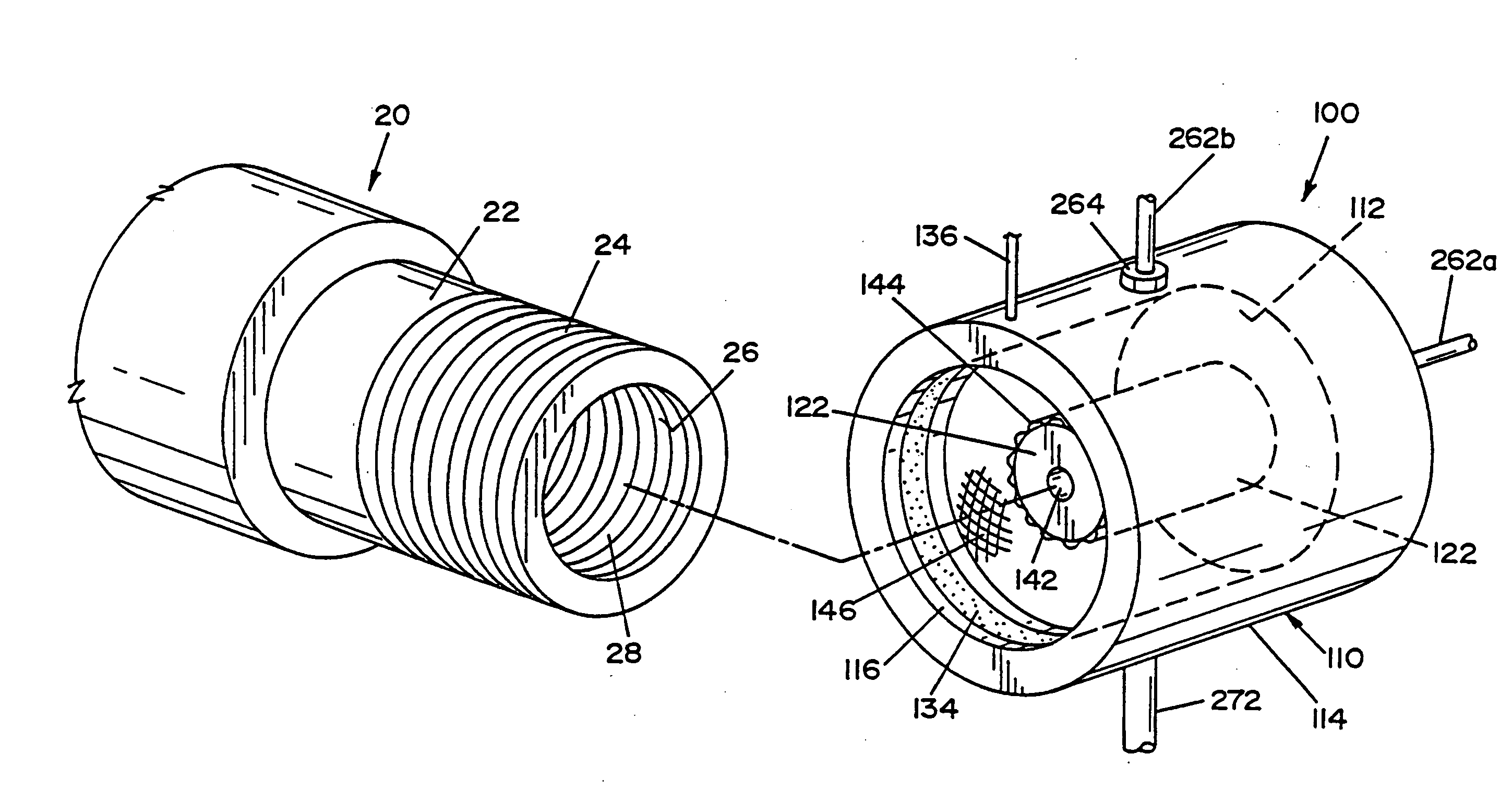

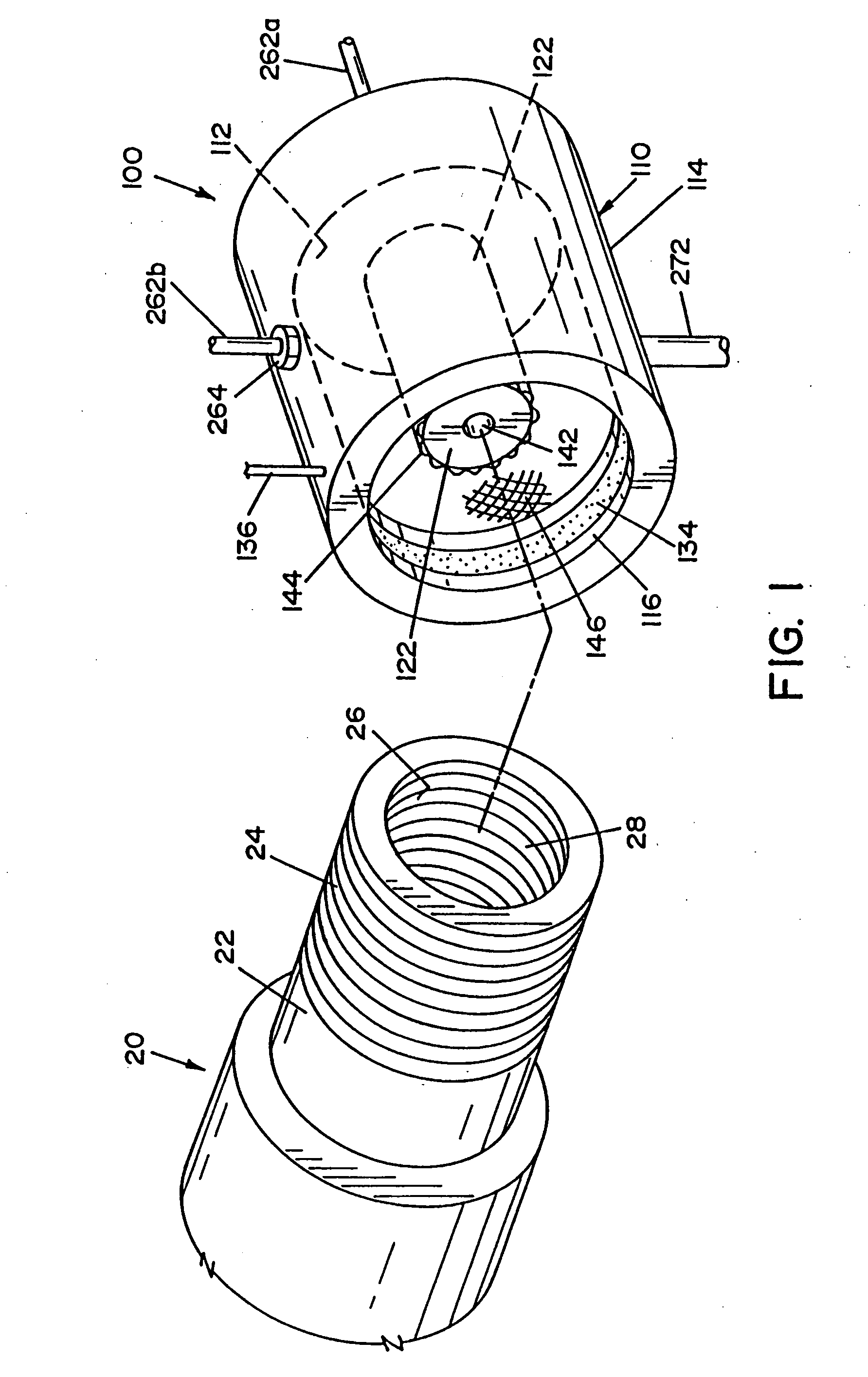

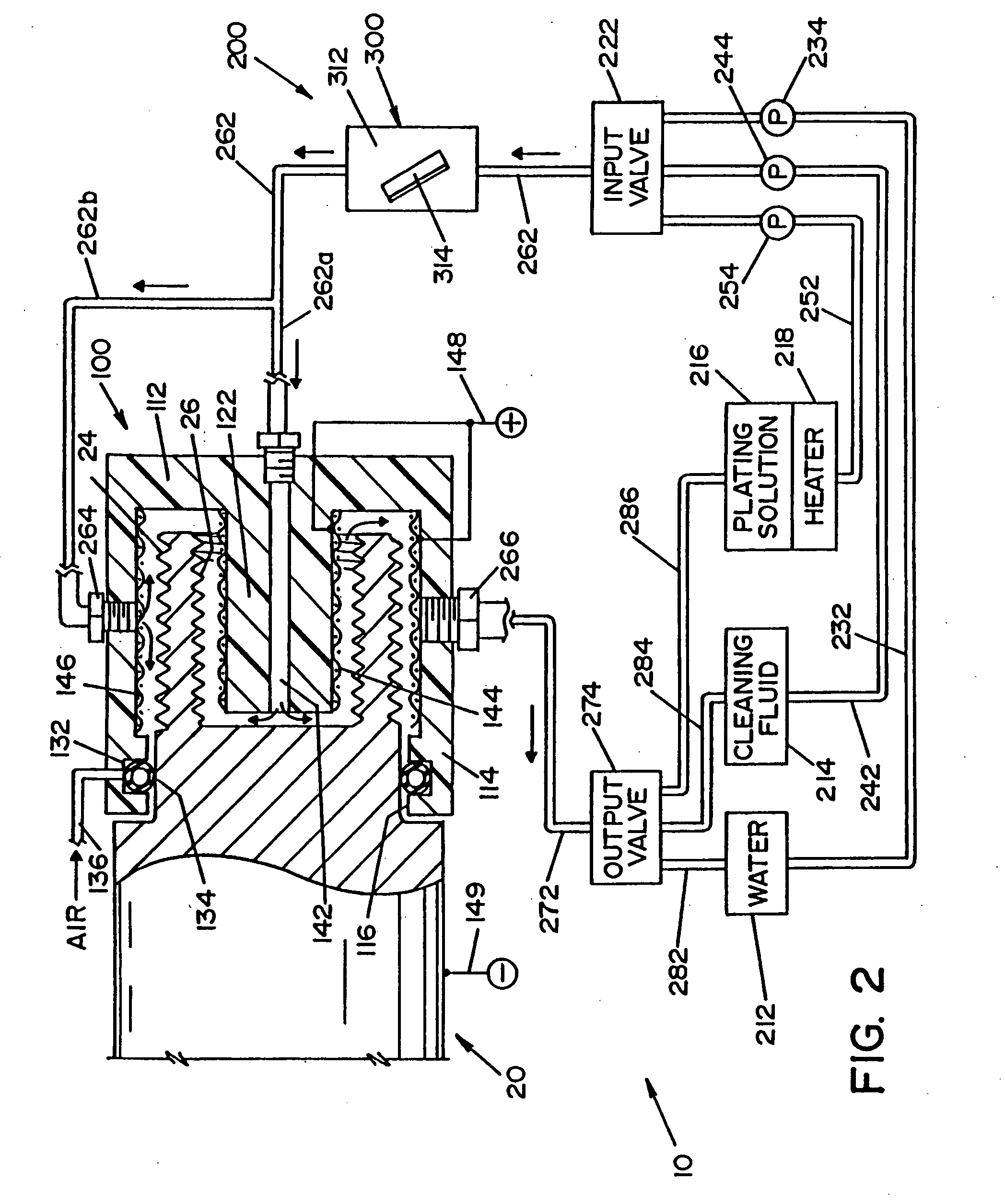

[0022] Referring now to the drawings wherein the showings are for the purpose of illustrating a preferred embodiment of the invention only, and not for the purpose of limiting same, the drawings show a plating system 10 for selectively plating select areas of a large work piece 20. The present invention is particularly applicable to plating screw threads on the ends of a long shaft, such as, by way of example and not limitation, the internal and external threads on the ends of a jet engine shaft, and shall be described with particular reference thereto. It shall be understood, however, that the present invention finds advantageous application in plating other types of work pieces. System 10 is generally comprised of a plating fixture 100, a fluid circulation system 200 and a test strip container 300.

[0023] Referring now to FIG. 1, work piece 20 is a shaft having a tubular end portion 22. Tubular end portion 22 has a threaded outer section 24 and a threaded inner section 26. Tubular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com