Wellhead drive brake system

a brake system and wellhead technology, applied in the direction of positive displacement liquid engines, well accessories, liquid fuel engines, etc., can solve the problems of rod string and pump being lost down the hole, rod string and pump being lost, and serious problems occured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

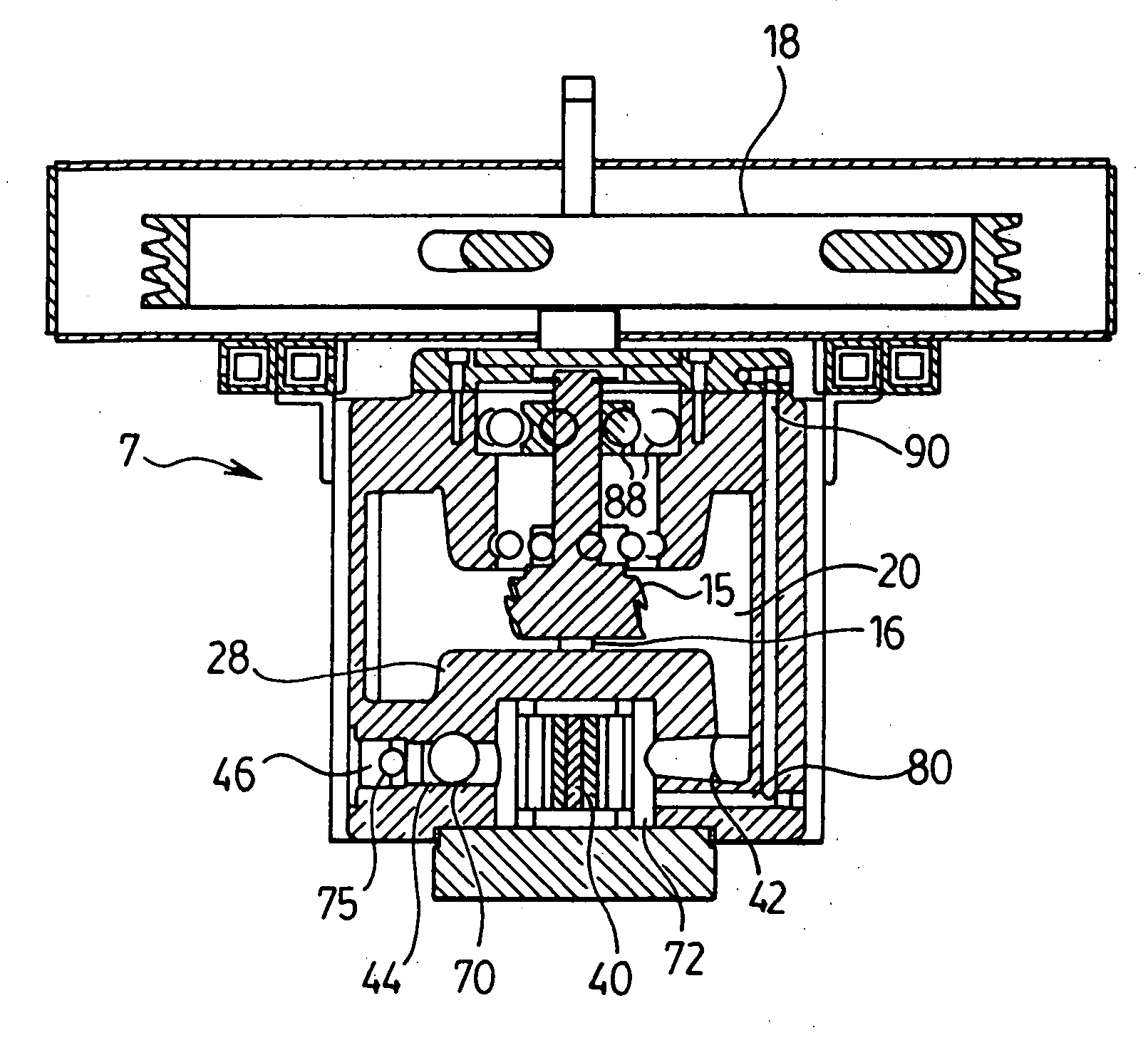

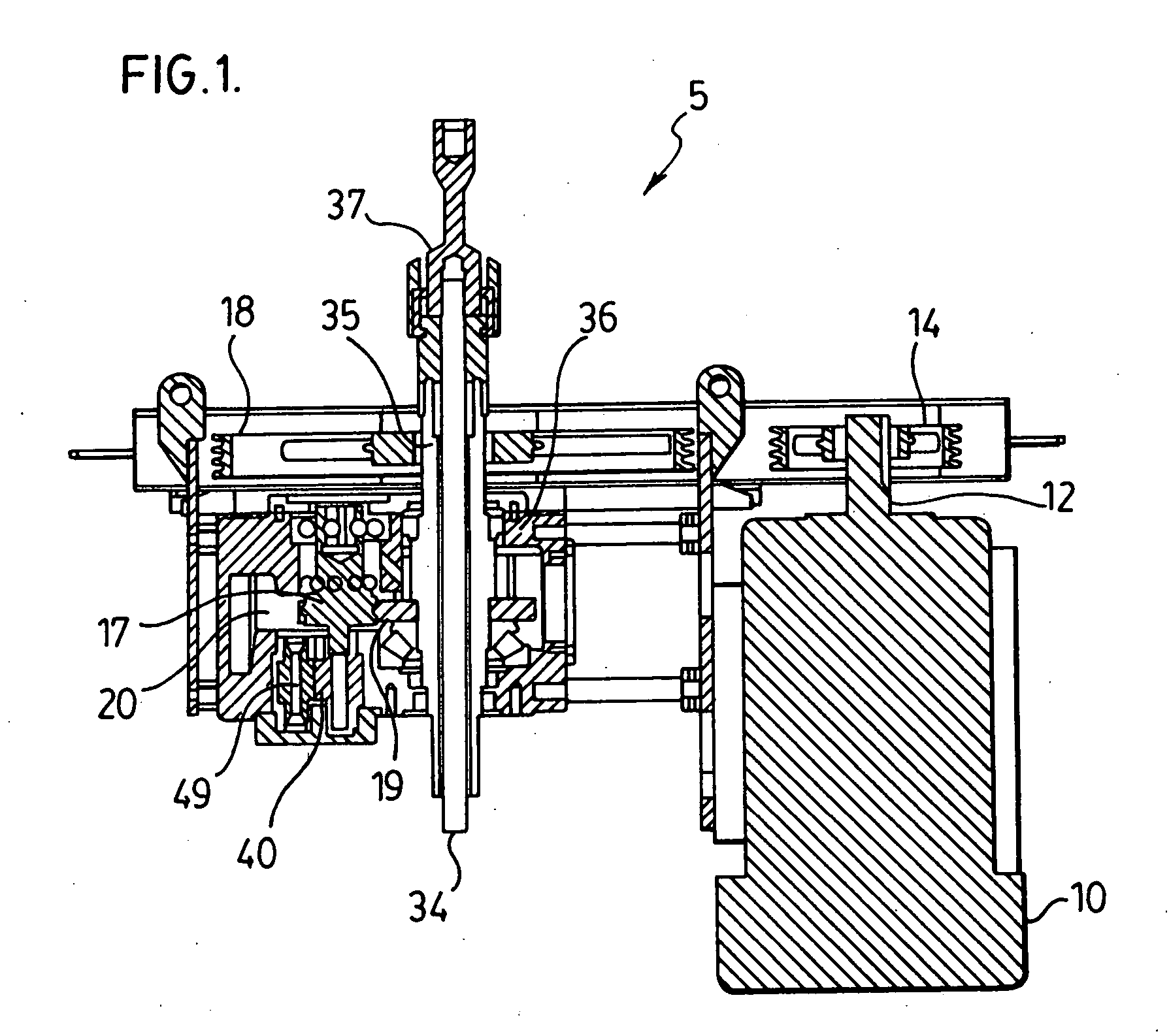

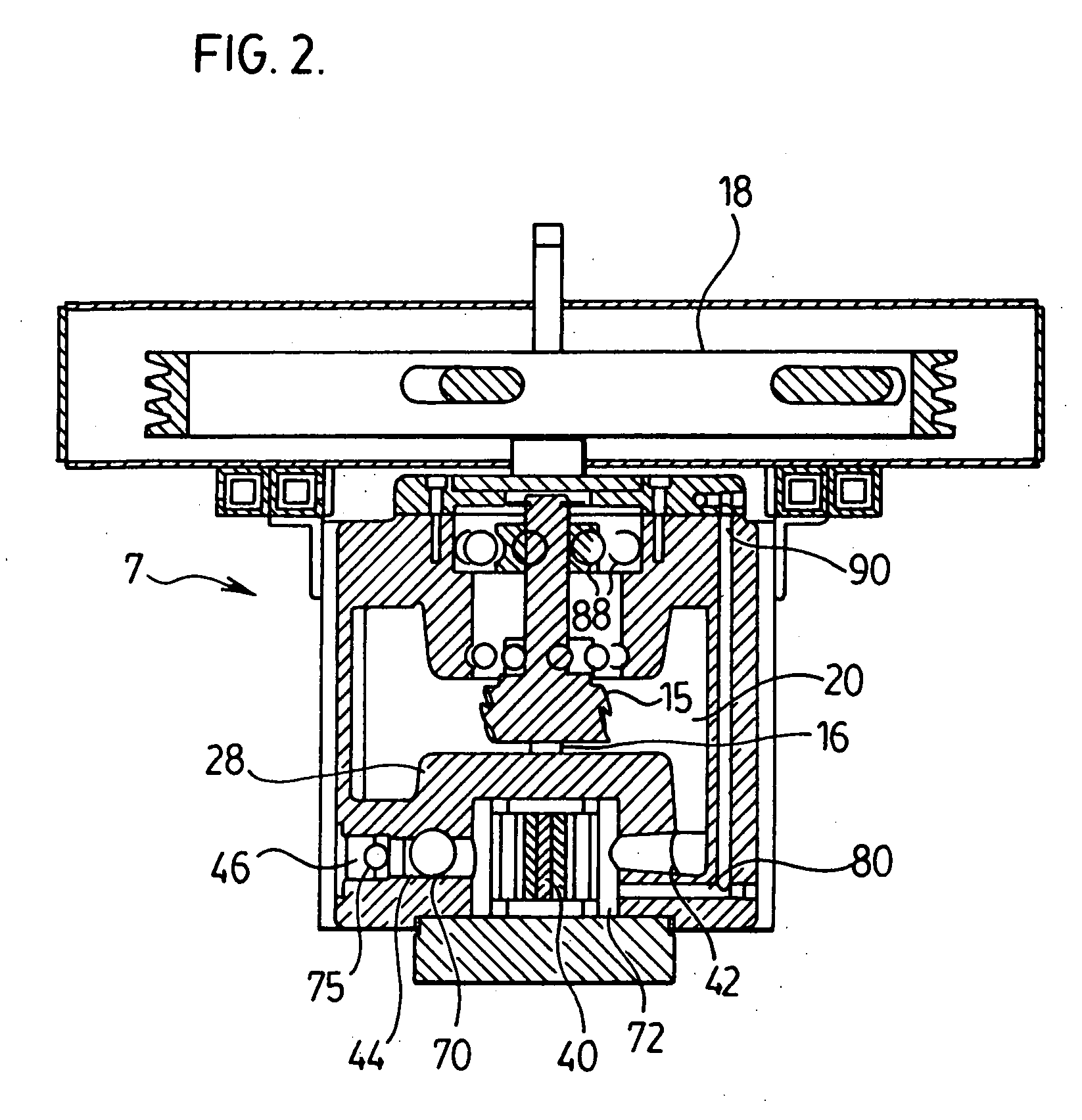

[0014] In one aspect, the present invention provides a braking mechanism which, without using a slip clutch, slows the backspin of a rod string by using the rotational energy of the rod string to turn a fluid pump to pump fluid through a constriction orifice in a closed fluid circuit. As compared to the prior art described in the background, the present invention reduces the space required for the braking mechanism and moreover reduces the number of moving parts within the braking mechanism which in turn may reduce the likelihood that the braking mechanism will require maintenance or fail, as well as reduce the manufacturing cost.

[0015] In another aspect, the present invention provides a wellhead drive system which employs the inventive braking mechanism in a wellhead drive system for driving a pump, for example a progressive cavity pump.

[0016] A preferred embodiment of the braking mechanism of the present invention is accomplished by providing for use with a pumping system in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com