Concrete pole base cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

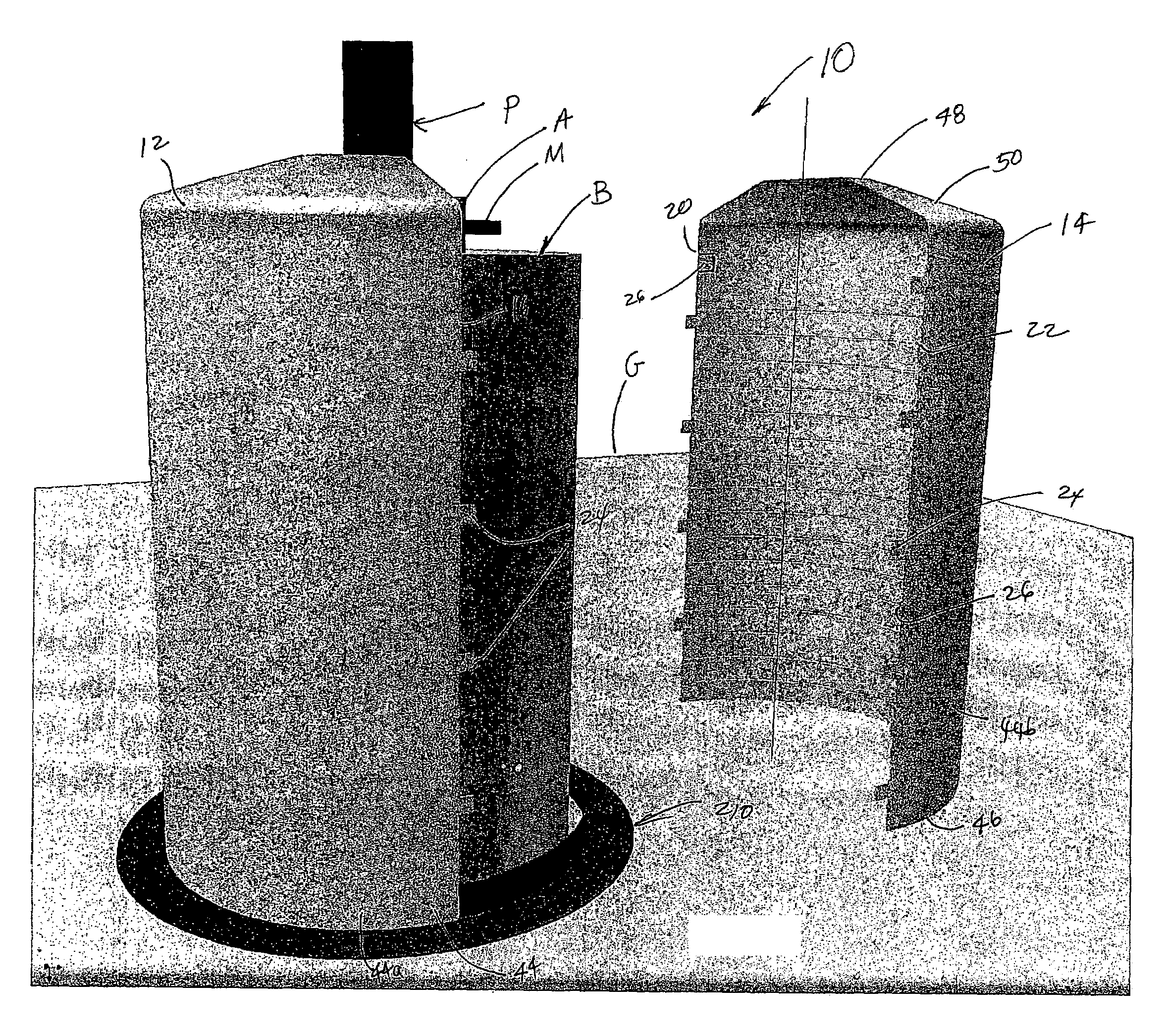

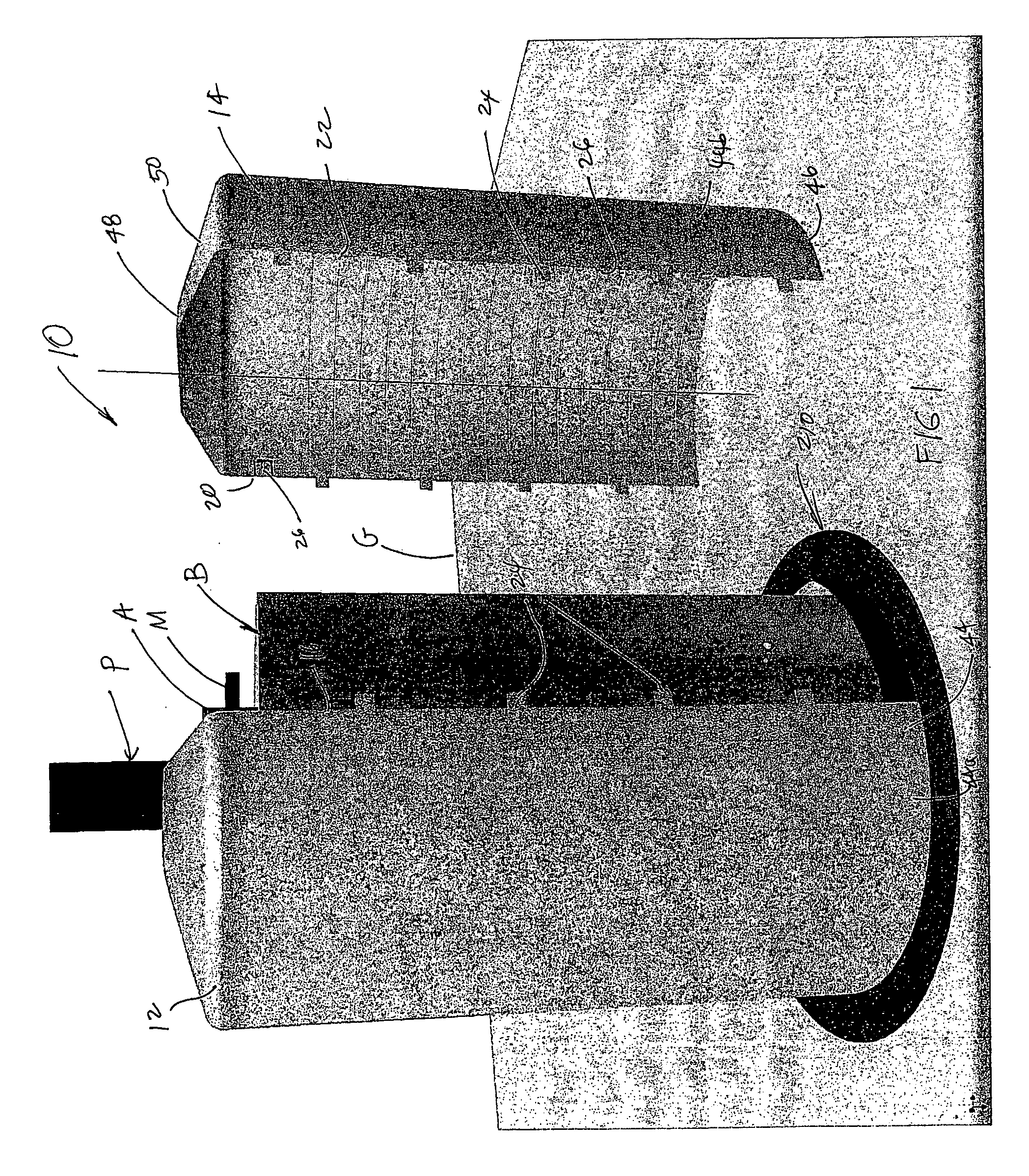

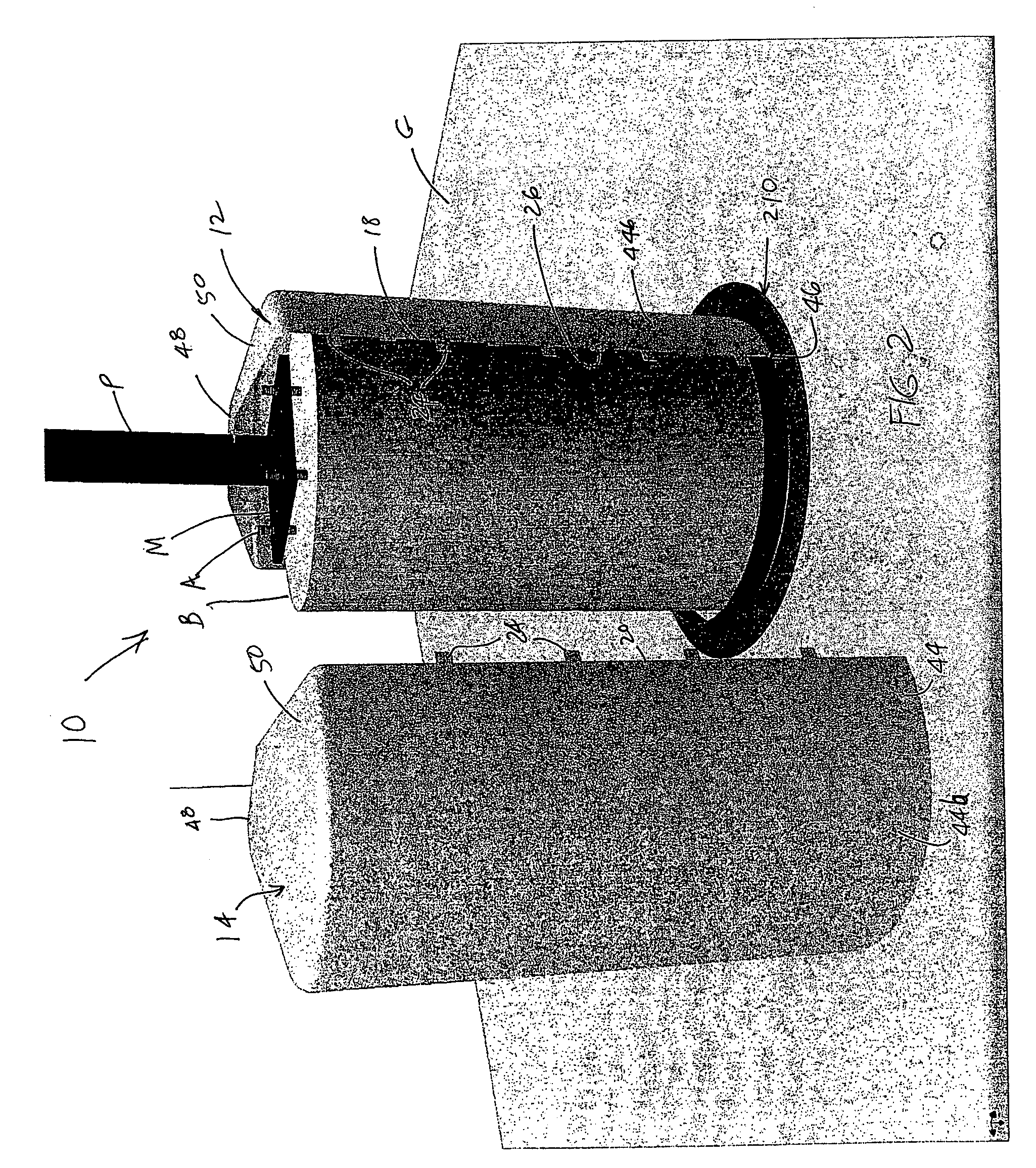

[0042]Referring to FIG. 1, the numeral 10 generally designates a cover of the present invention, which is particularly suitable for use on a pole assembly P, especially a lamp pole assembly, to cover the pole assembly's concrete base B and pole base plate M and optionally the concrete anchor bolts A that anchor the post to the base. As will be more fully described below, cover 10 will protect the concrete base from damage or corrosion due to sprinkler water, flying debris from lawn mowers, and will also cover defects or stains in the base.

[0043]In the illustrated embodiment, cover 10 includes a split housing construction with first and second cover halves 12 and 14, each having a substantially identical construction so that they may be molded or formed from the same mold. When mounted about pole assembly P and base B, cover 10 preferably covers the full length of the exposed portion of base B, which is typically cast in place and partially embedded in the ground G, so that cover 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com