Adsorption heat exchanger

a heat exchanger and adsorption technology, applied in the field of adsorption coated heat exchangers, can solve the problems of uneven heat dissipation of adsorbent coating layer, uneven thickness of adsorption coating layer, etc., and achieve the effect of reducing heat dissipation and mass transfer, reducing heat dissipation and heat dissipation, and reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0058]A plot of specific power (kW / kg) as a function of cycle time (sec.) is shown in FIG. 6. As it can be seen, high specific power can be achieved at a much shorter cycle time in comparison with current tube-plate design. Several fin densities (fpi) for the adsorption layer were considered. Wash coating process calls for optimum fpi number. An fpi number of more then 11 may not be suitable for some applications due to poor drainage of extra wash coat after its application onto the fin-plate structure.

example 2

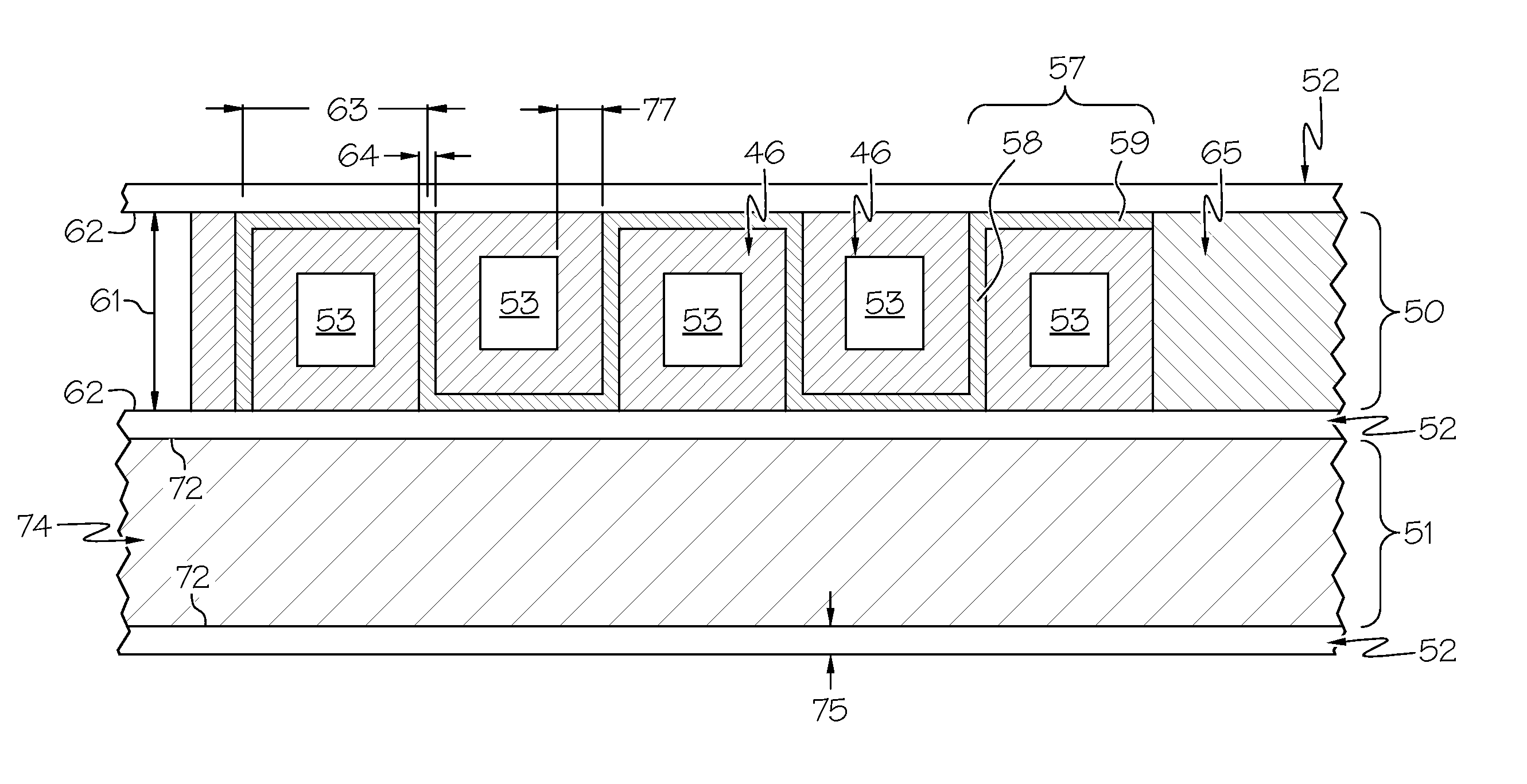

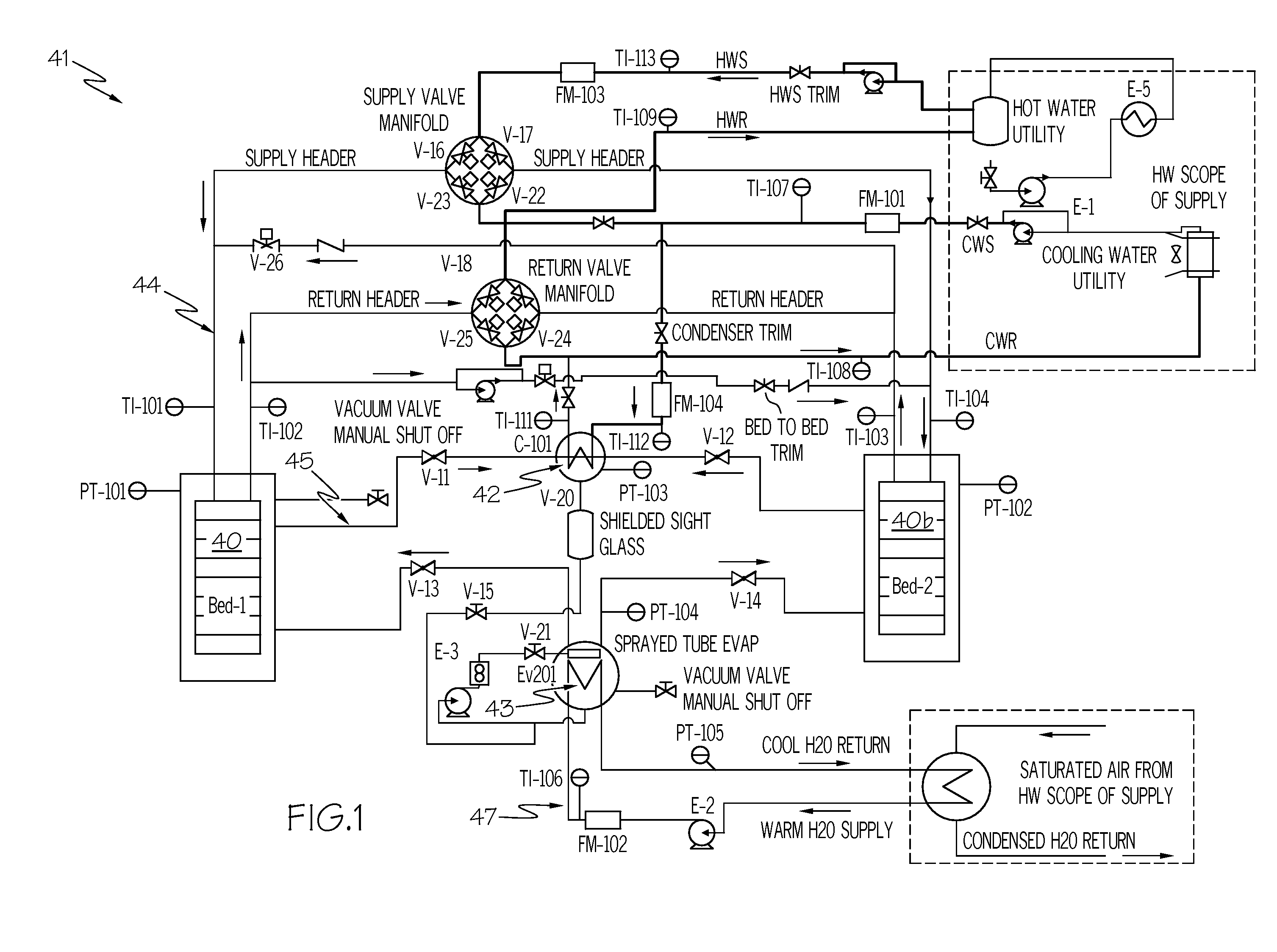

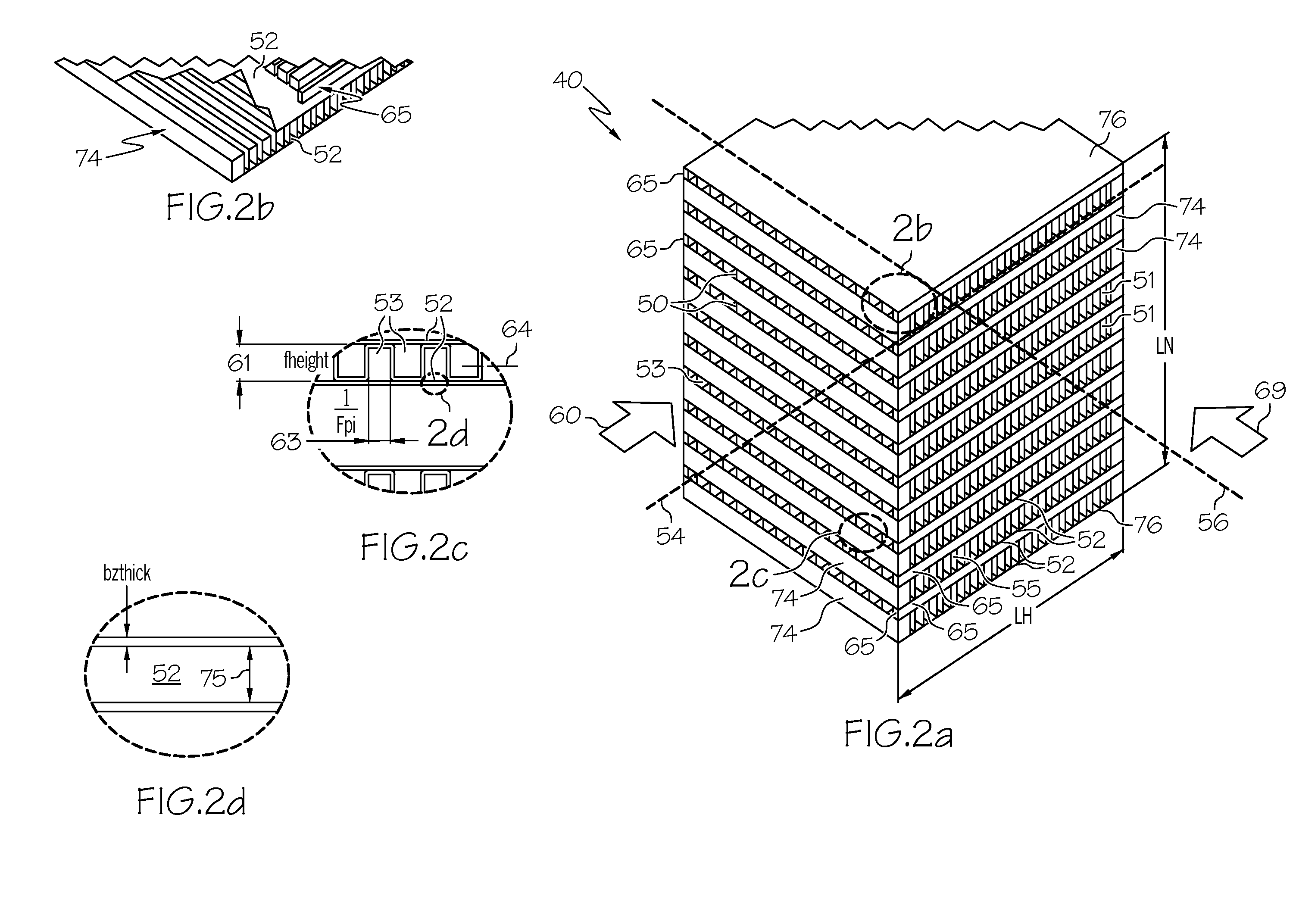

[0059]The design parameters for one embodiment of the present invention are shown FIG. 7. In this example, the components (fins, plates, etc.) comprise aluminum. Dynamic simulation results of h for adsorption side (h=553 / BTU / hr.ft2.R) and fpi=11 were used for the adsorption heat exchanger design. The calculated design parameters for adsorption side (adsorption layer 50) and HT side (Ethylene Glycol / Water, (EGW) (heat transfer layer 51) are shown in FIG. 7. During the sorptive cooling process, adsorption / desorption side of adsorption heat exchanger was under a total pressure of 5-80 torr depending on the mode (i.e. adsorption or desorption). The geometry of an embodiment of the adsorption heat exchanger is shown on FIG. 8. The estimated adsorption heat exchanger core dry weight is 6.7 lb. As can be seen, embodiments of the present invention can increase adsorptive material surface area while reducing adsorption heat exchanger overall dimensions.

example 3

[0060]The sensitivity results on adsorption material coating thickness variations are shown in FIG. 9. The results show that specific power decreases when adsorption material coating thickness increases. Absolute cooling power increases with the increased adsorption material coating thickness. It should be noted here that adsorption side heat transfer coefficient would be slightly changed due to different adsorption material coating thickness, which was not considered in the sensitivity study.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com