Holder for mixer buckets

a technology for mixer buckets and holders, which is applied to machine supports, furniture parts, other domestic objects, etc., can solve the problems of buckets that slide around on the floor or spin out of control, none of them seem to be durable, economical of manufacture, durable in use, etc., and achieves the effect of greatly facilitating the mixing operation, quick and easy transportation from the job si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

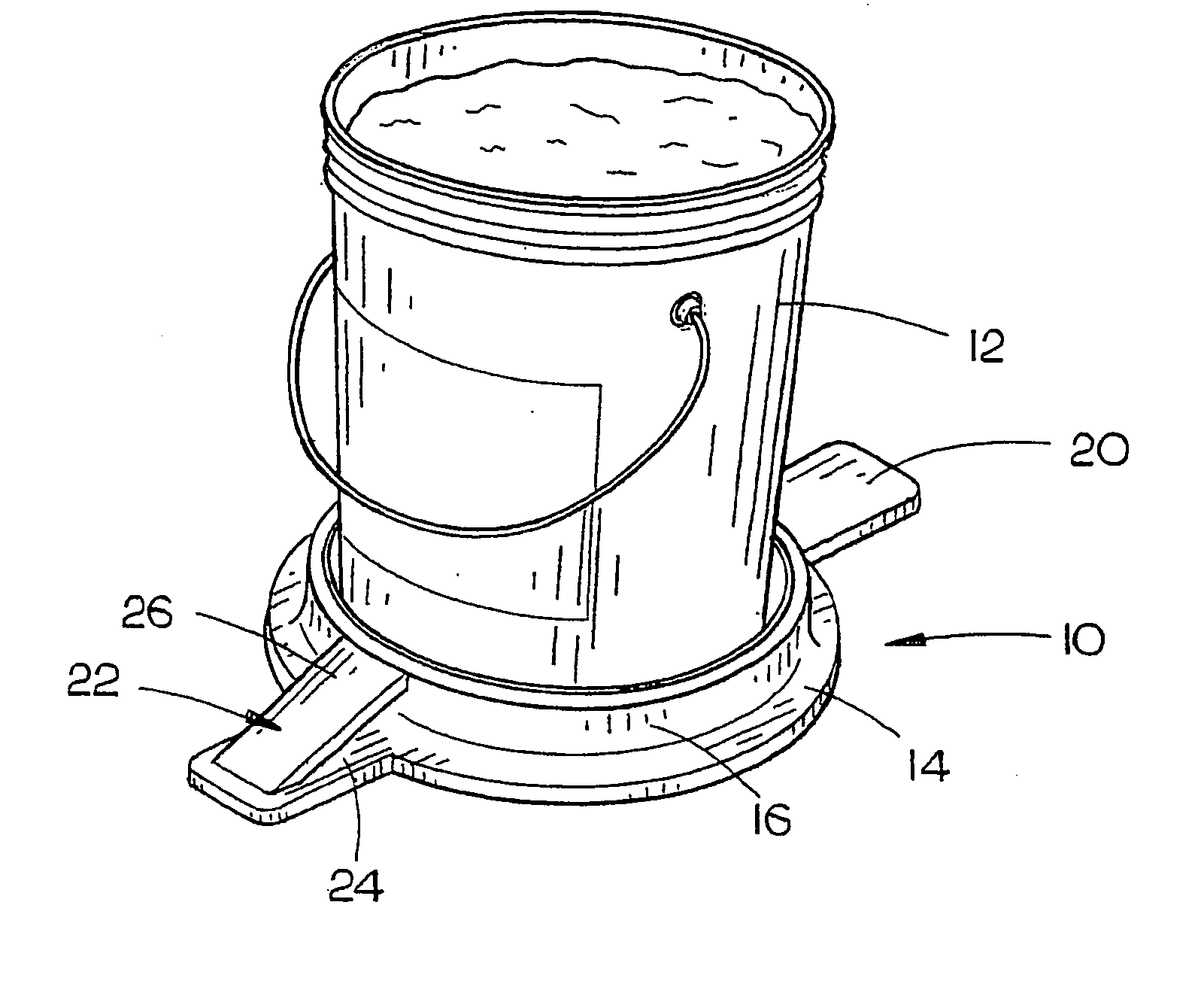

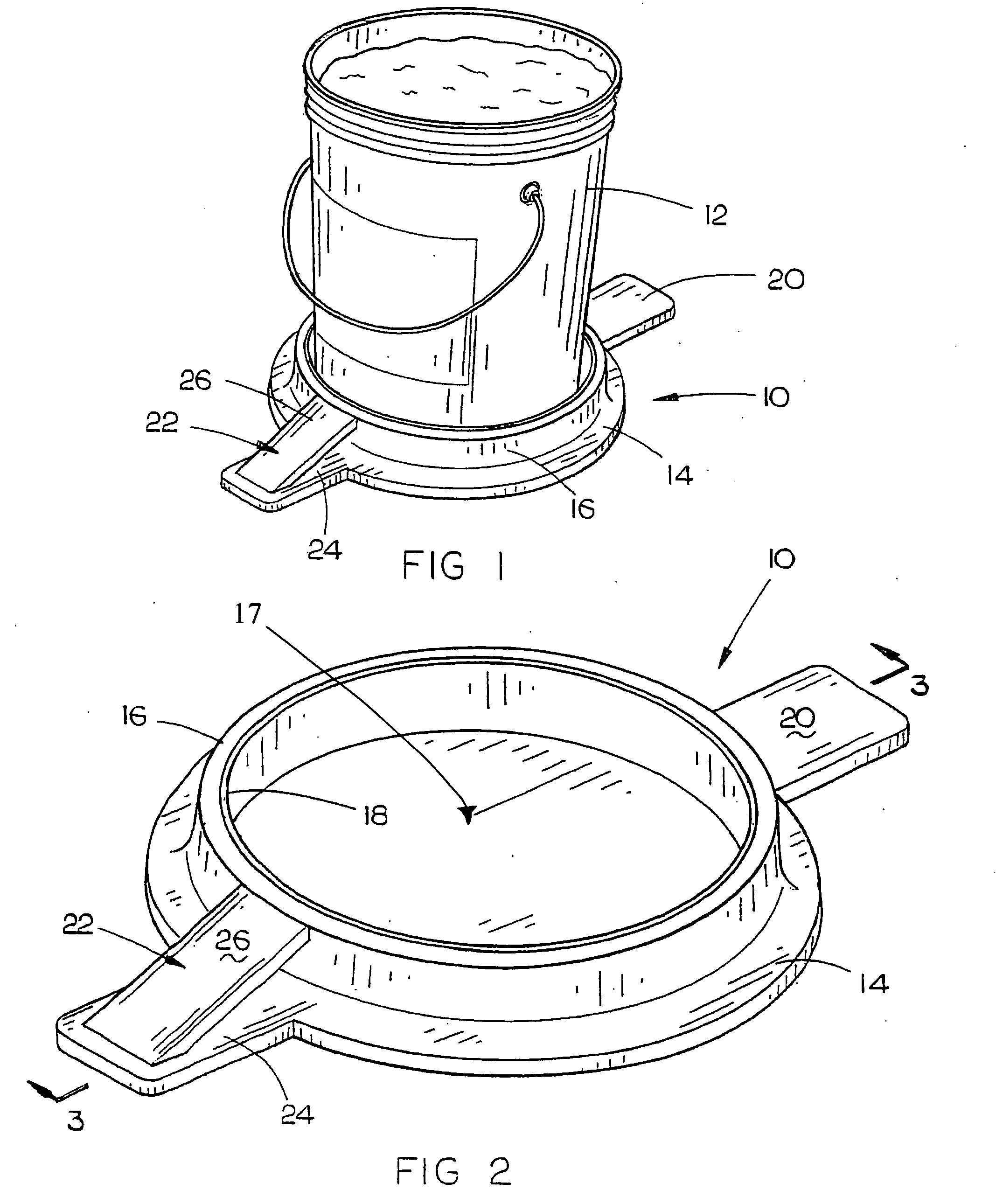

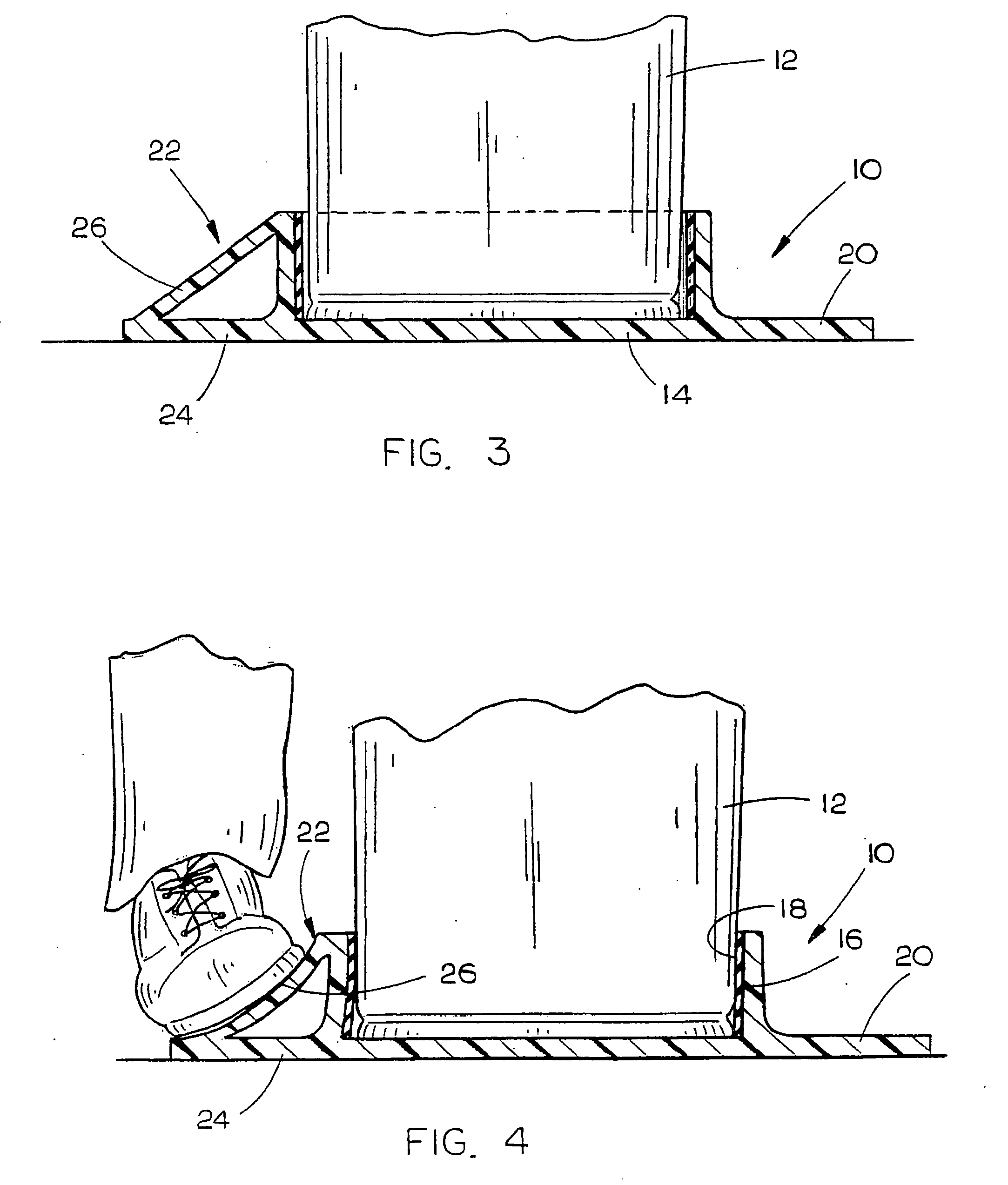

[0018]The holder of this invention is generally designated by the reference numeral 10 which is preferably of a one-piece, molded plastic material. The holder 10 is designed to hold a bucket or pail 12 (hereinafter “bucket”) in place while the contents of the bucket are being mixed by a power mixer.

[0019]Holder 10 includes a flat, planar, disc-shaped base plate 14 and an upstanding wall member 16. In the preferred embodiment, the diameter of the wall member 16 is less than the diameter of the base plate 14 although, in some cases, the wall member 16 could have the same diameter as the base plate 14. In other words, the wall member 16 could extend upwardly from base plate 14 at the outer periphery thereof. Preferably, an anti-skid material 18, such as rubber, is applied to the inner surface of the wall member 16 to aid in gripping the bucket as will be described hereinafter. An anti-skid material may also be applied to the upper surface and to the bottom surface of the base plate 14 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap