Electromagnetic Pump

a technology of electromagnetism and pumps, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of difficult service and maintenance of pump installations, and achieve the effect of maximizing the magnitude of magnetic forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

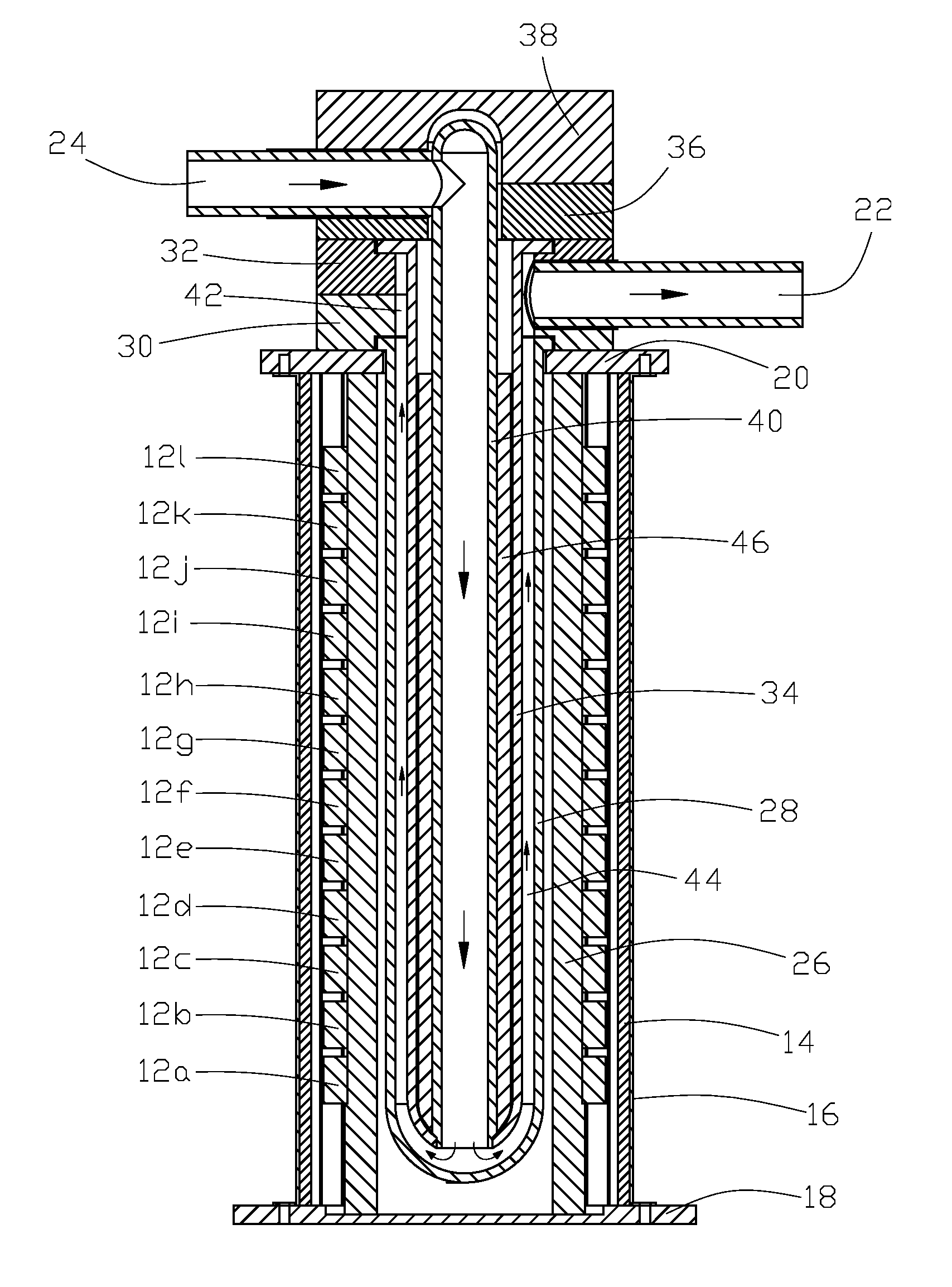

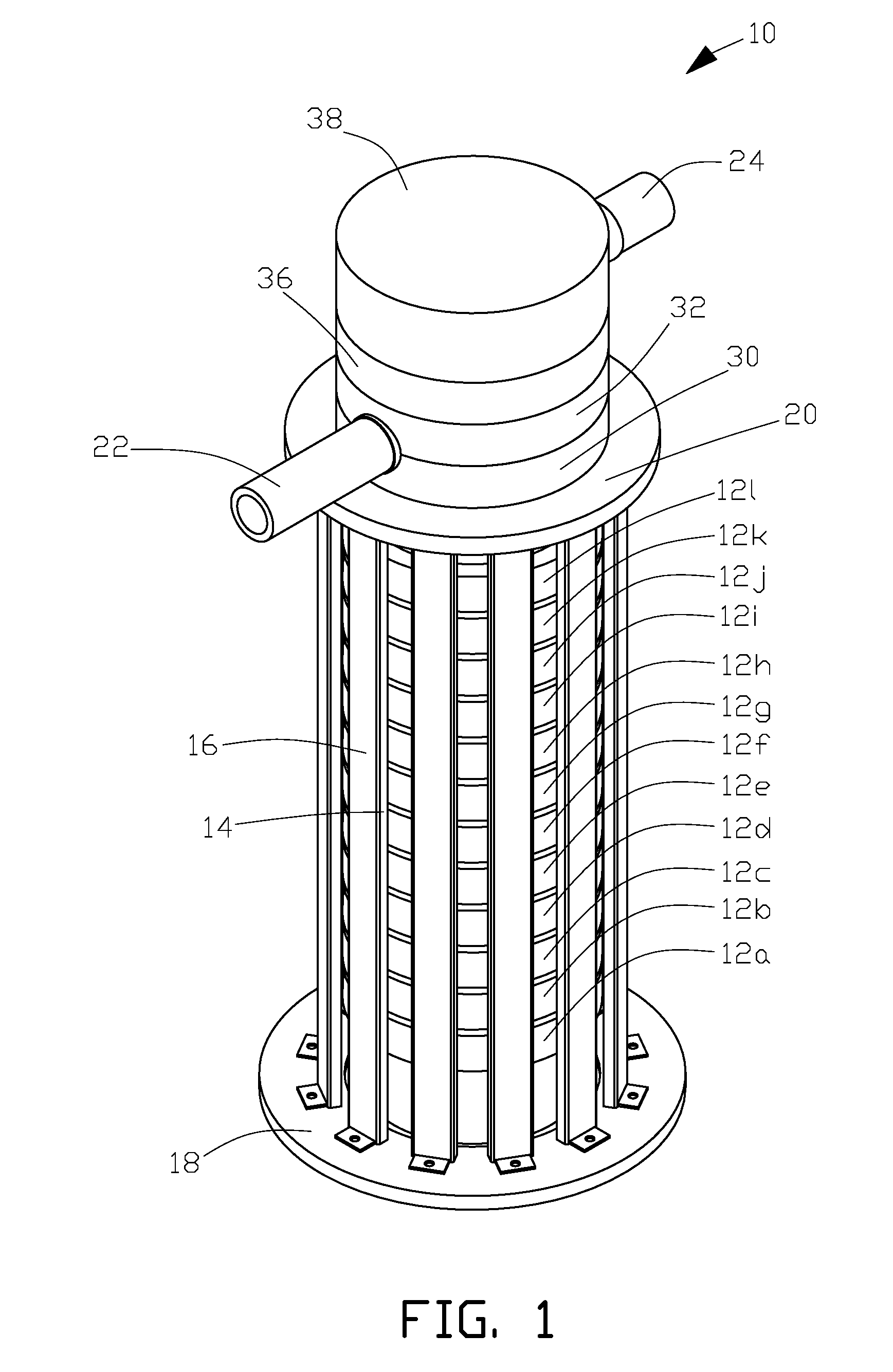

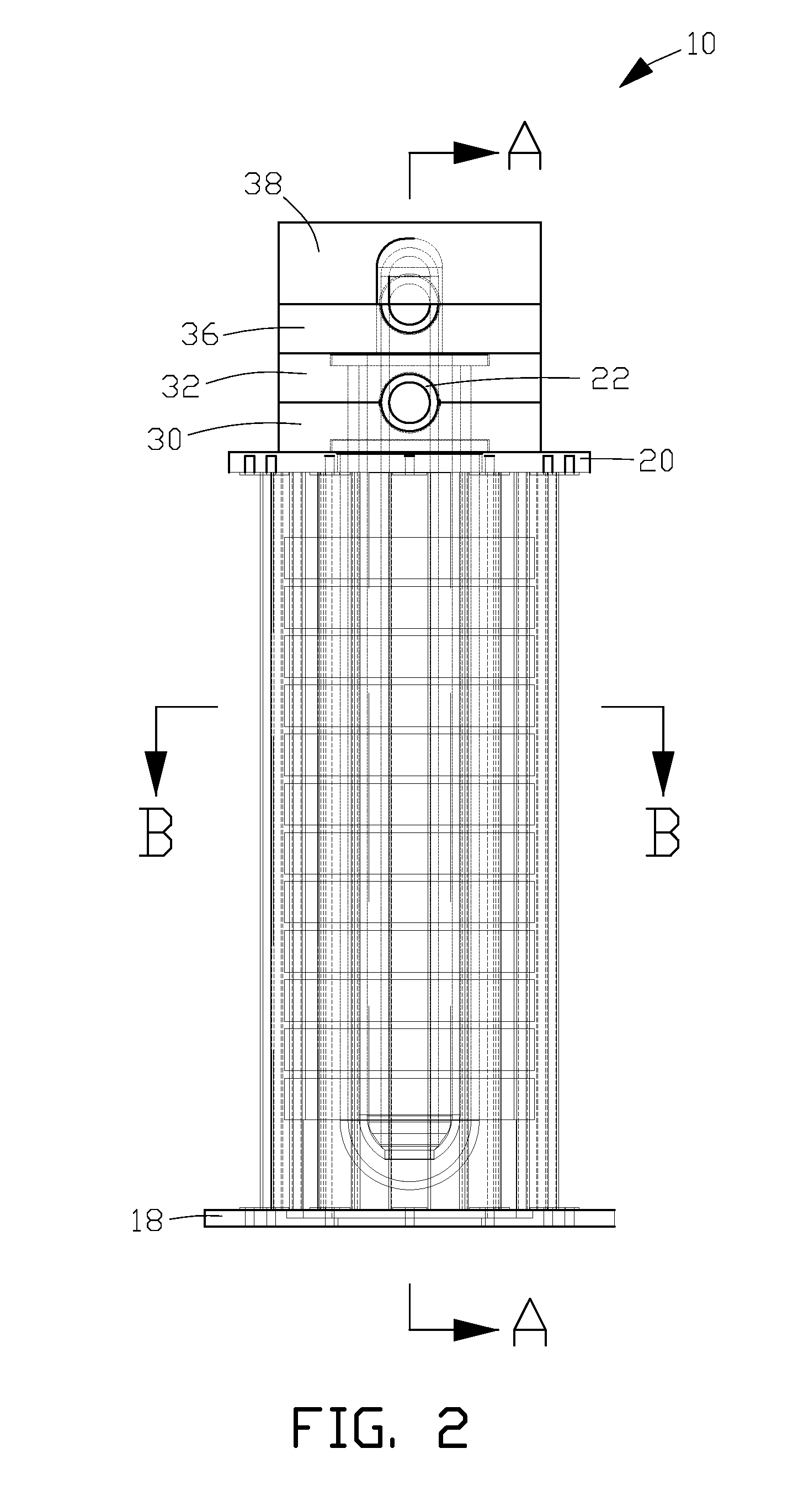

[0016] Referring now to the drawings, wherein like numerals indicate like elements, there is shown in the figures one example of electromagnetic pump 10 of the present invention for pumping an electrically conductive material, such as an electrically conductive molten metal. In FIG. 1, twelve induction coils (12a through 12l) as further described below, are surrounded by a plurality of vertical magnetic shunts 14 held in place by shunt supports 16, which are attached to base 18 at one end, and to yoke 20 at the opposing end. The base and yoke may optionally be formed from a magnetic material to provide bottom and top magnetic field containment. Other shunt and outer support arrangements as known in the art may be used in lieu of the shunt and support arrangements shown in FIG. 1. Pump inlet 24 and pump outlet 22 in this non-limiting example of the invention, are cylindrically formed from a suitable heat-resistant material.

[0017] Referring now to FIG. 3(a), which is a side sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com