Footwear construction

a technology for footwear and construction, applied in the field of footwear, can solve the problems of reducing comfort, reducing comfort, and subsequently comfort, and reducing the comfort and wearability of footwear, so as to achieve the effect of improving flexibility and comfort, high degree of support, and adding flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Overview

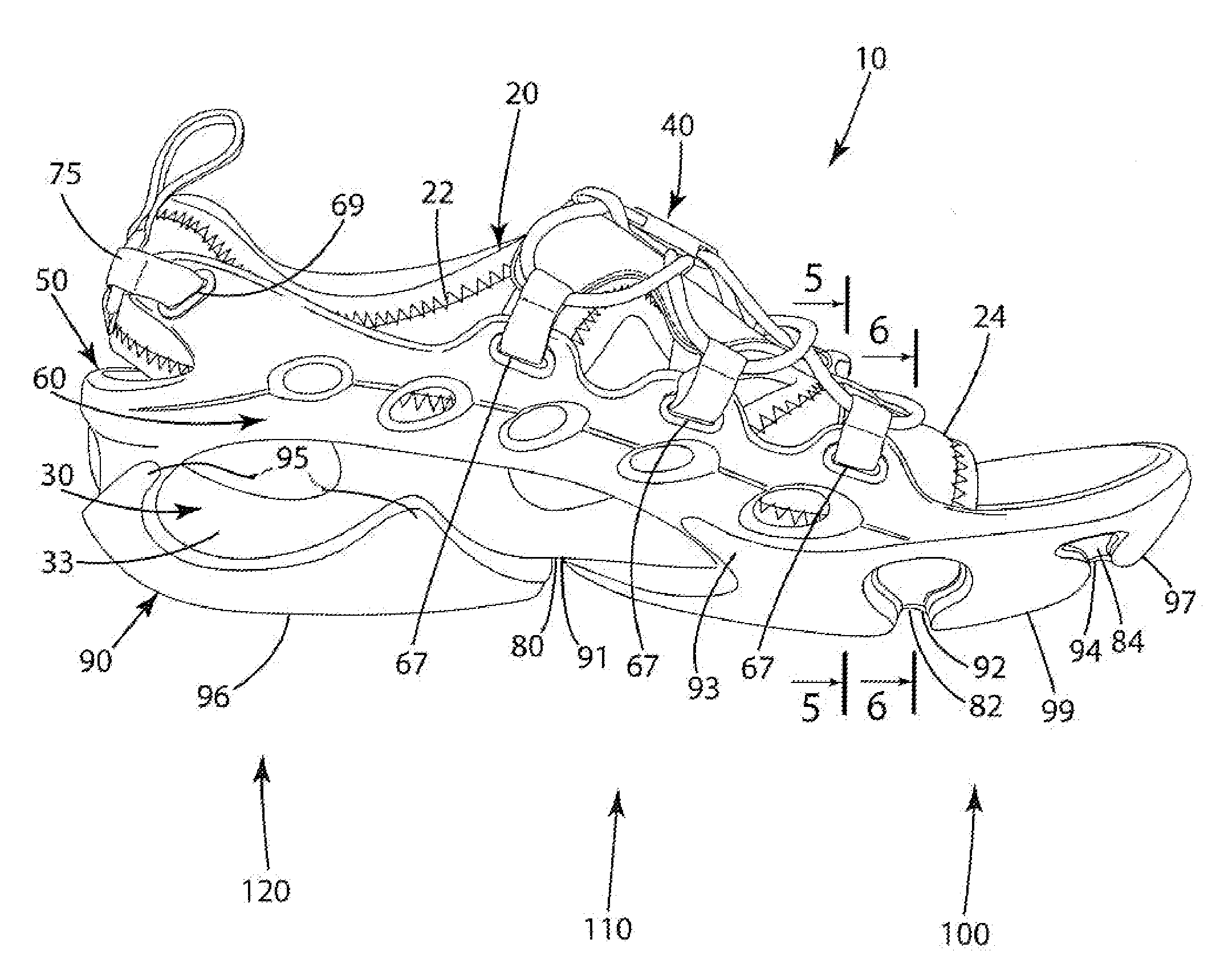

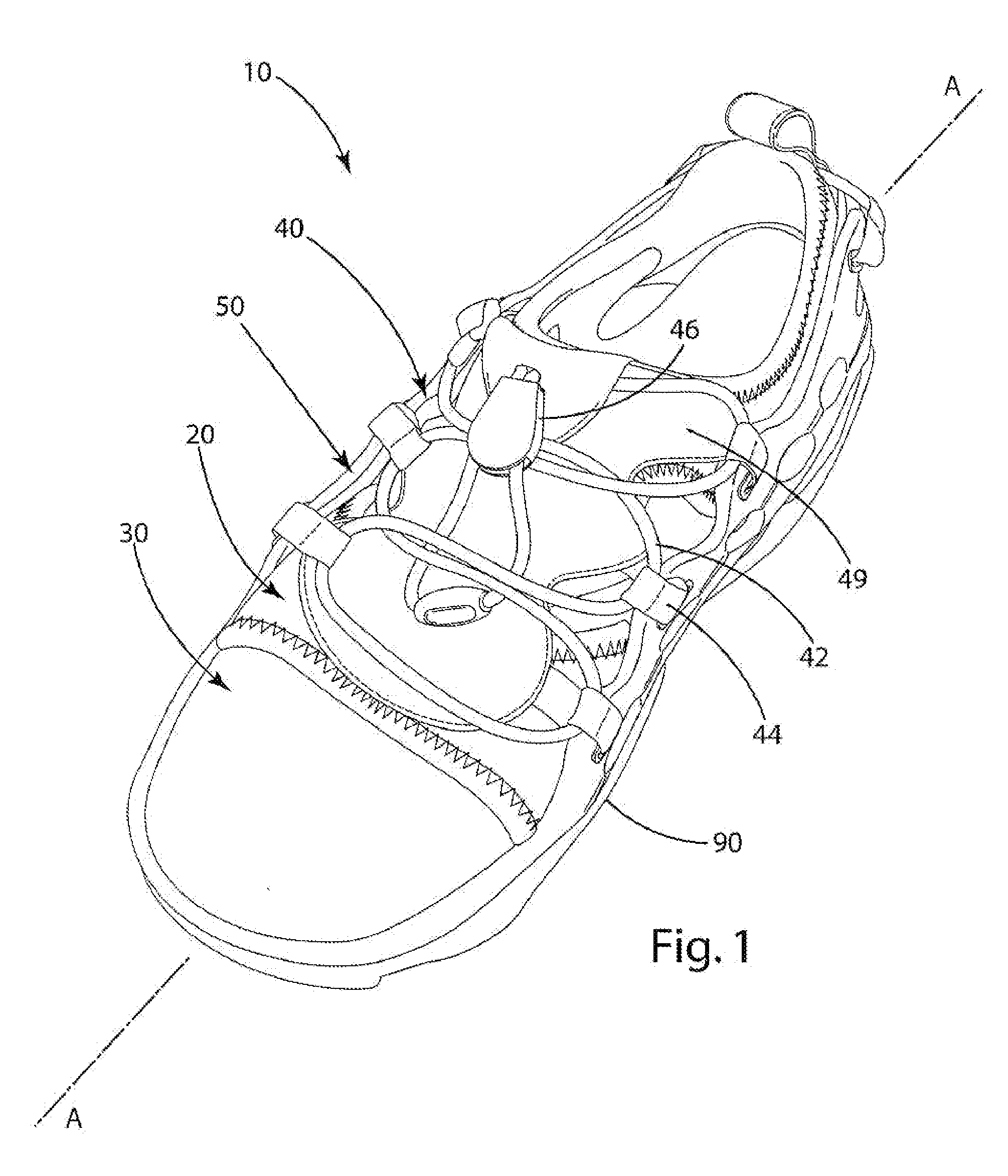

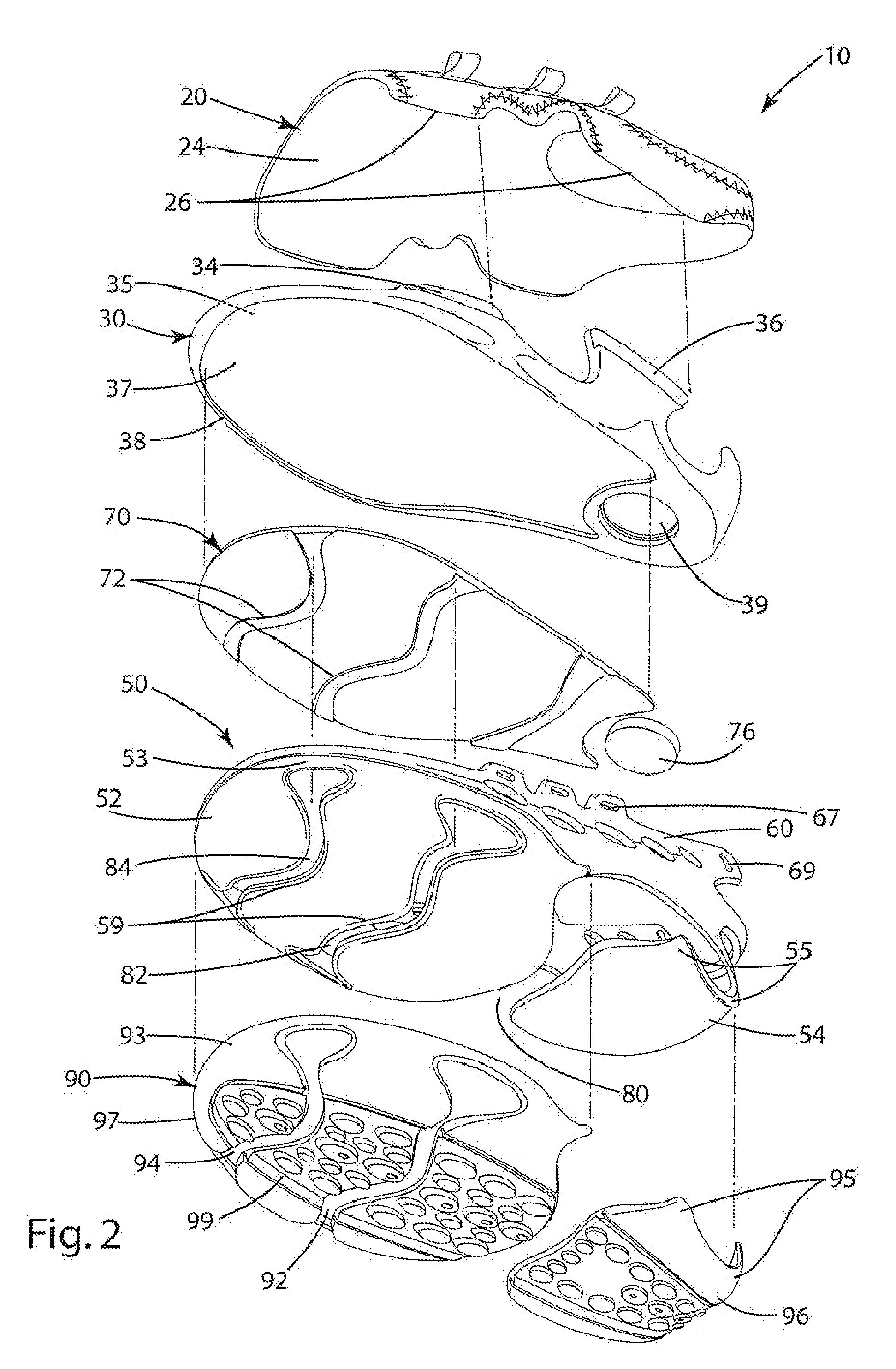

[0018]Footwear constructed in accordance with a preferred embodiment is shown in FIGS. 1-6 and generally designated 10. The footwear 10 includes an upper 20 joined with a midsole 30, which is further joined with a midsole frame 50, which is joined with an outsole 90. A closure 40 can be joined with the midsole frame 50 and / or upper 20 to further secure the footwear on the foot of a wearer. The midsole frame 50 can include a forefoot frame base 52 and a heel frame base 54, which are joined by an intermediate frame section 60. Optionally, a plate 70 can be included in the footwear between the midsole 30 and the midsole frame 50. The midsole frame 50 and outsole 90 can each include voids SO, 82, 84 and 91, 92, 94, which are generally aligned with one another, respectively. When included, these voids can provide improved flexion of the footwear along the longitudinal axis A of the footwear to reduce fatigue on the wearer's foot.

[0019]For purposes of disclosure, the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com