Batch filtration system for preparation of sterile fluid for renal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

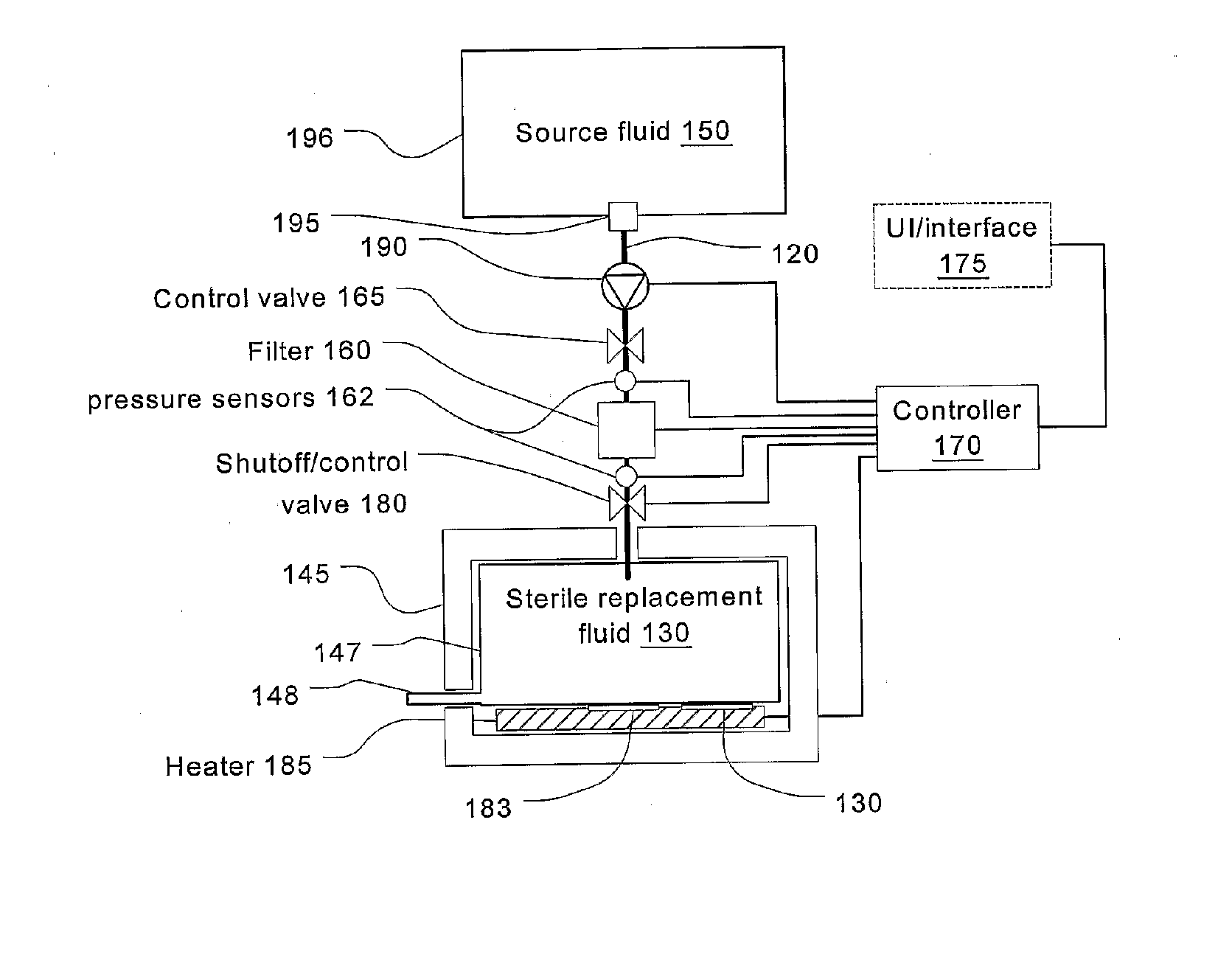

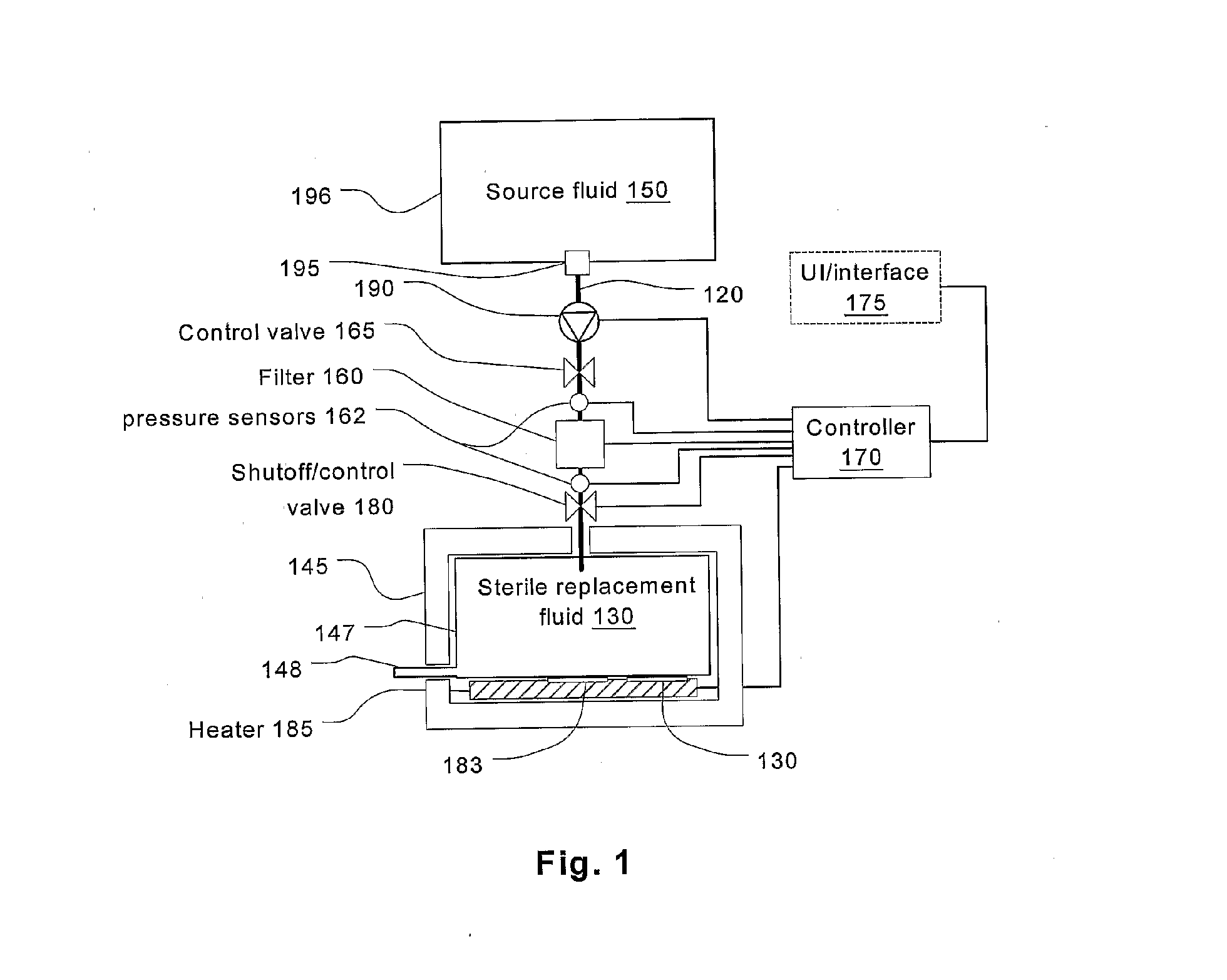

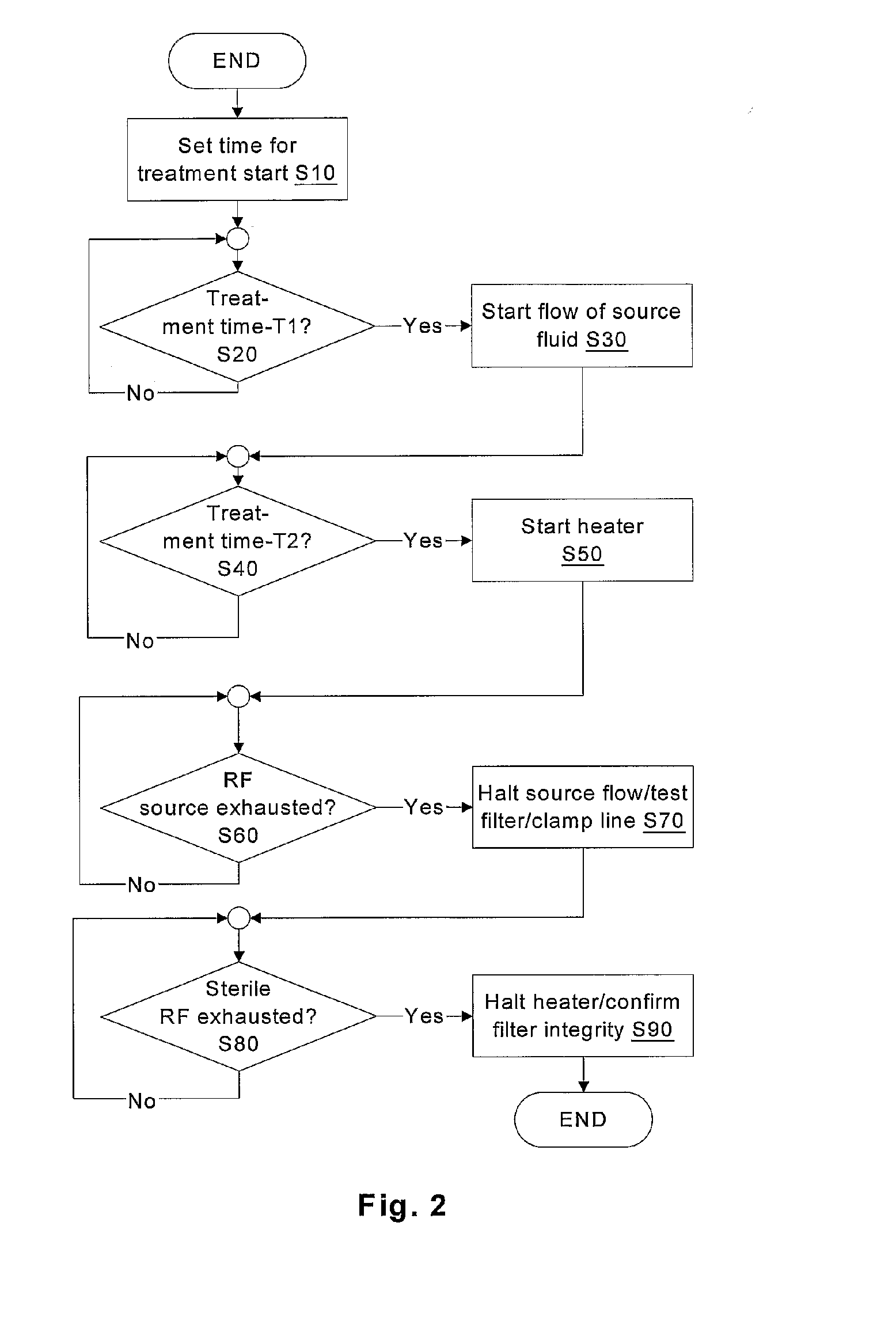

[0022] Referring to FIG. 1, a filter 160 filters fluid from a source of fluid 150 to generate a batch of sterile replacement fluid 130. The filter 160 may be, and preferably is, a microporous filter that blocks all materials except dissolved electrolytes and water. Thus, the result of the filtration process is to sterilize the raw fluid from the source of fluid 150. The source of fluid 150 may be a container of sterile or non-sterile replacement fluid, one or more containers of constituents which, when combined, form a proper replacement fluid. Any of the latter may include a continuous source such as a water tap. One or more conduit elements form a line 120 to convey the source fluid 150 through the filter 160 and into a batch container 147.

[0023] The latter may be any type of sterile, preferably disposable container, for example, a large IV bag. It may also include a number of such containers appropriately interconnected to permit flow into and out of them in the fashion of conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com