Wet shaving system including a mineral oil coated shaving aid

a technology of wet shaving and mineral oil, applied in the direction of metal working devices, etc., can solve the problems of excessive shaving discomfort, composite tends to swell, and application may be too late to prevent unwanted effects, so as to improve shaving comfort and glide. , the effect of inhibiting the swelling inhibiting the water absorption of the shaving aid composi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

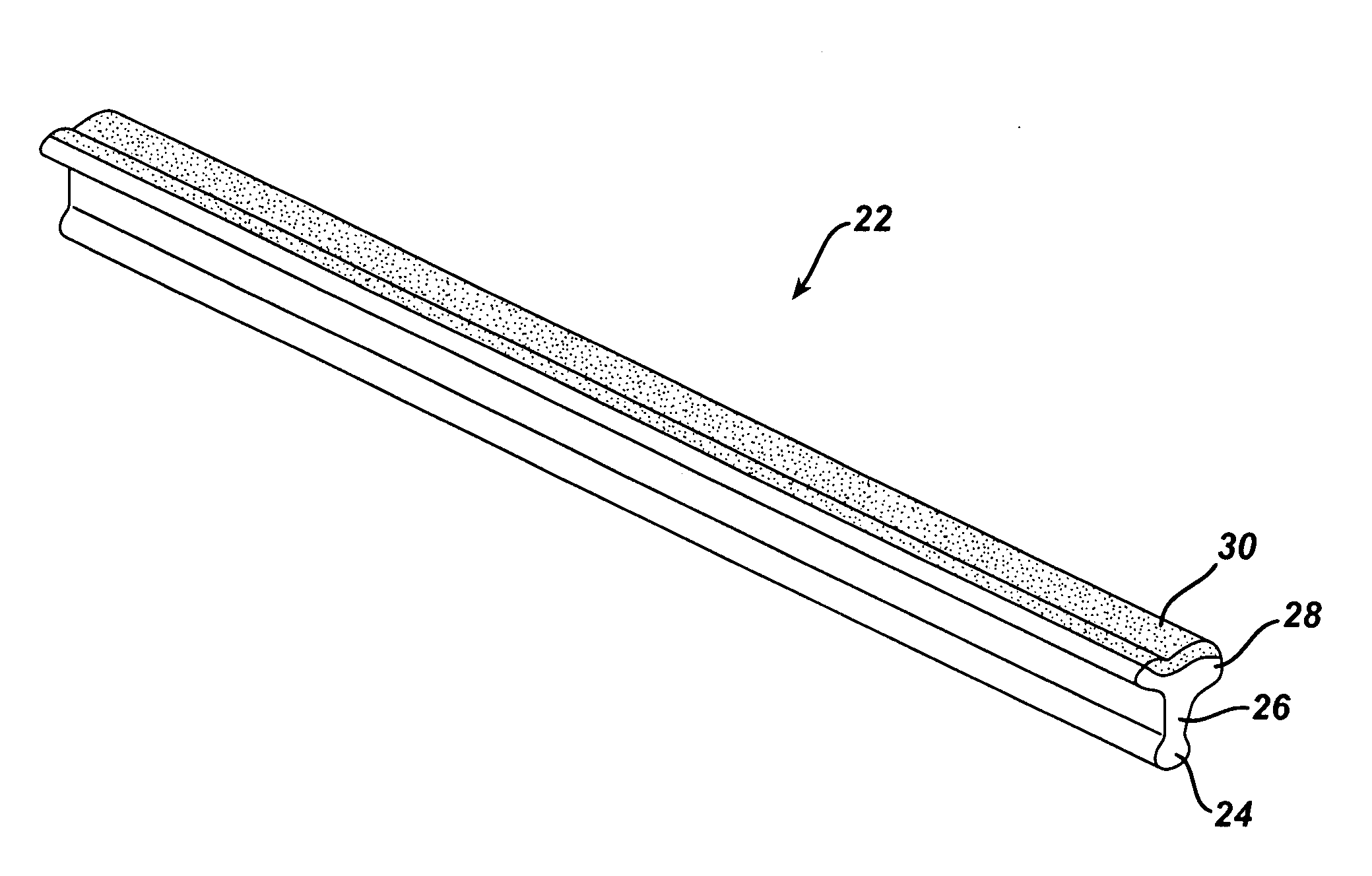

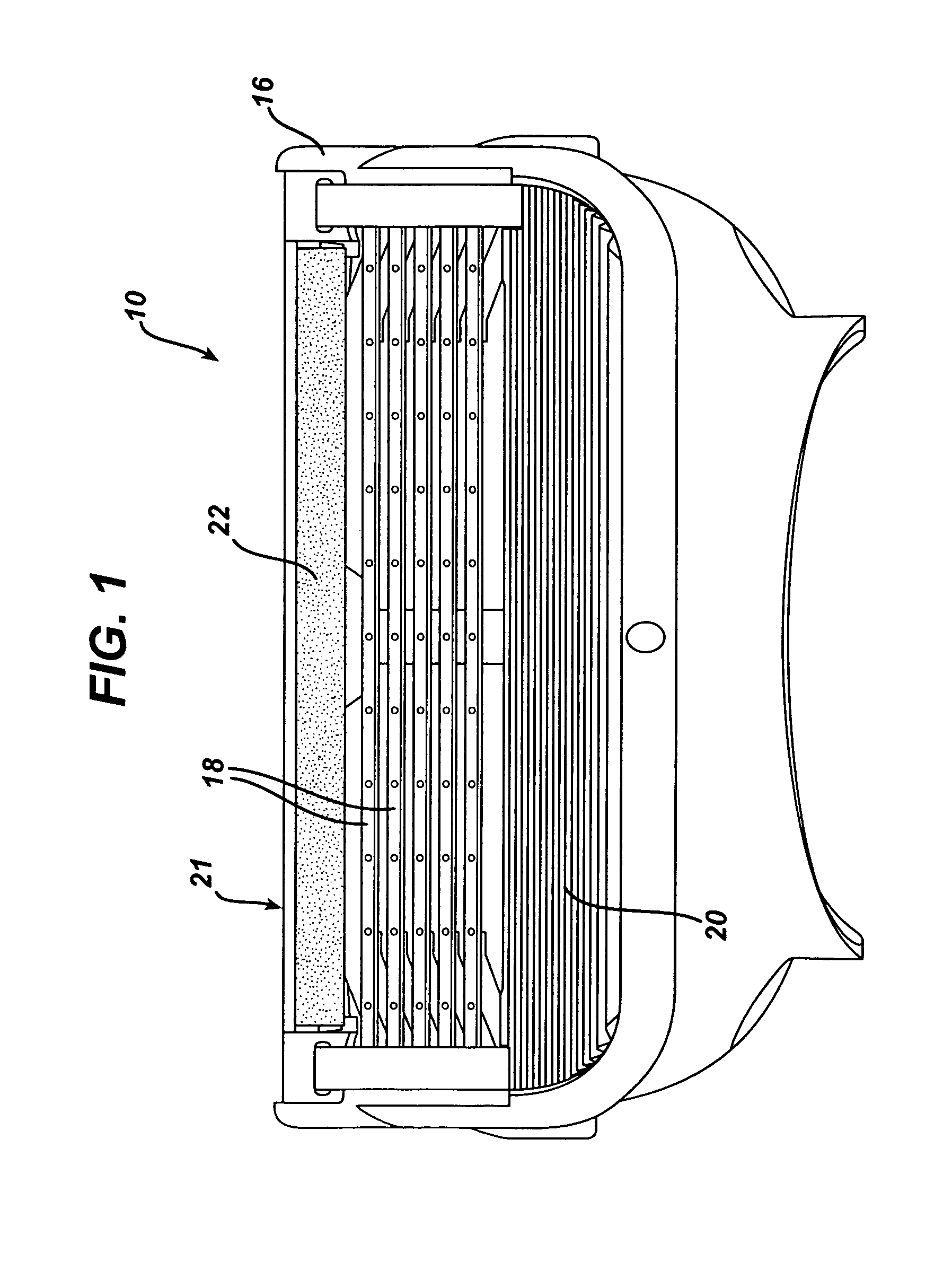

[0019]The replaceable shaving system 10 shown in FIG. 1 includes a housing 16, which carries a plurality of blades 18, a guard 20, and a cap 21. A portion of the cap 21 includes a solid, polymeric shaving aid composite 22, which is in the form of an elongated insert member. The shaving aid composite 22 is locked in an opening in the rear of the shaving system and includes a shaving aid that is released during shaving to improve shave attributes. While shown at the rear portion (commonly referred to as the cap portion) of this particular shaving system, the shaving aid composite may be located at any skin-engaging portion of the shaving unit and may be fabricated in any size or shape deemed appropriate. For example, the composite can be incorporated into the shaving units described in U.S. Pat. No. 4,586,225, which is incorporated herein by reference.

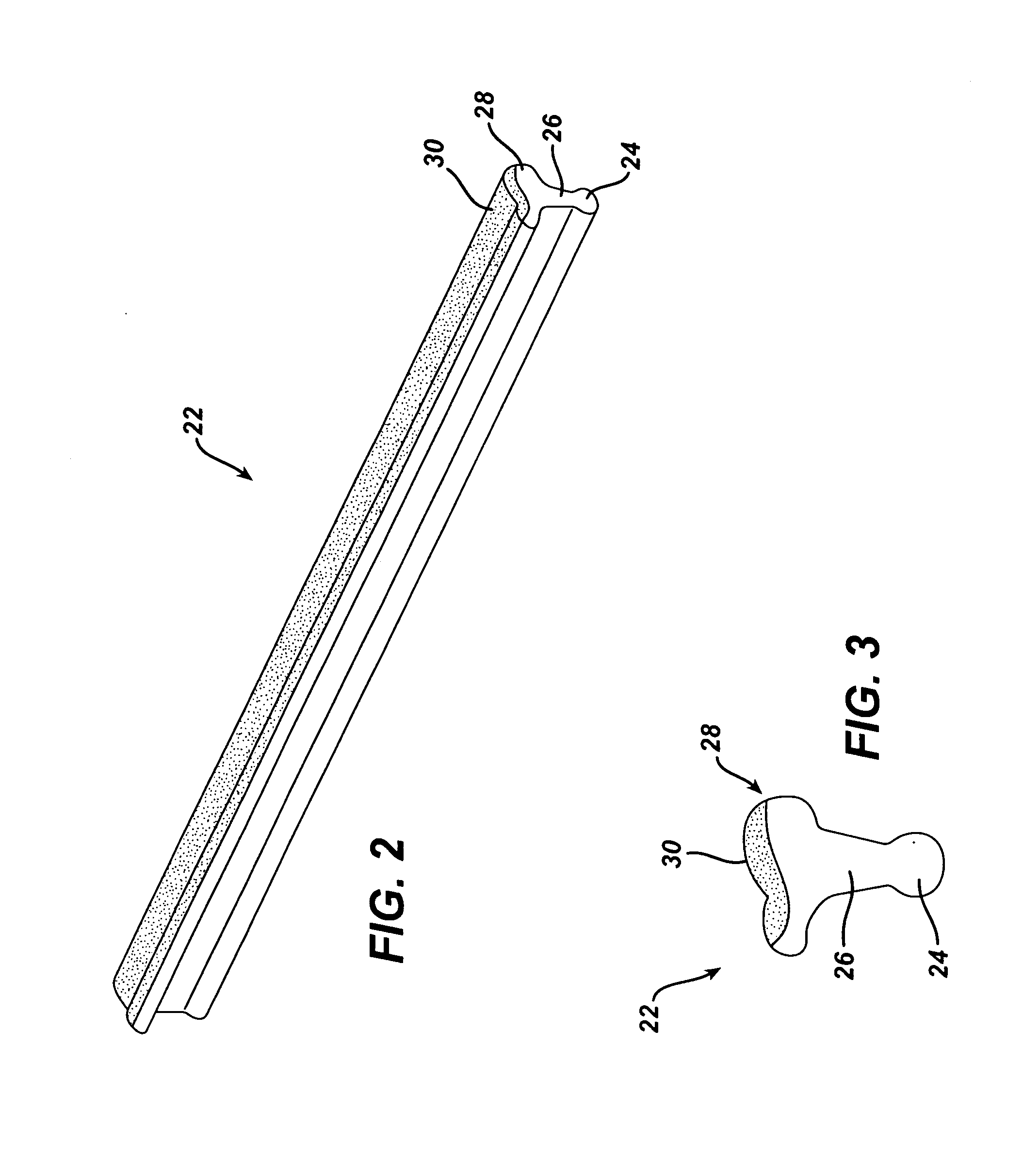

[0020]While the shaving aid composite may have any desired shape, one preferred shape is shown in FIGS. 2 and 3, in which shaving aid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com