[0024] An another

advantage of the invention is that the influencing of fiber orientation and the influencing of basis weight cross profile in the headbox are as independent from each other as possible. In other words, by means of the invention the fiber orientation (sectional) is possible alone with a directed

sound field, while the headbox controls only the desired basis weight cross profile. It is also intended that by use of a sectional density controlled headbox, the fiber orientation in the consecutive former can improved by the present invention.

[0025] But not only fibers can be aligned with a directed

sound field: generally color particles haven't a sphere form. The kaolin used in

paper production has a lamella like structure. By reason of the above mentioned facts it is understandable that color particles can also be aligned by the proposed method. If the color particles—or, for example, little

metal plates—are mixed into the suspension and the wave fronts are parallel to the surface of the fiber web, so the particles or the little

metal plates will also undergo a parallel orientation to the surface of the fiber web. If the

sound field in this embodiment does not effect the whole width of the fiber web, a

colored signature in the fiber web is possible, which is translucent in the dry fiber web. If the sound field additionally is oscillating and / or intermitting, so line shaped or pattern shaped signatures can be designed. This has the

advantage that, for example, paper documents and also paper money can be provided with a kind of signature, which is positioned inside the paper and not printed on the paper and therefore exceptionally counterfeitproof. But in this way the fibers are also alignable so that, for example, with a special lamp the inventive signature can be read or checked. This method of reading works by

light reflection and / or light transition.

[0026] Color particles in the

sump of a

coating machine or color particles at the surface of a fiber web in a coating machine can also be aligned, by means of the invention, parallel to the fiber web surface. There is the

advantage that the irregular color plates can be aligned in

layers and therefore the aligned plates can better glide relative to each other at the coating operation or the doctoring process. This means that the shearing stress in the coating color can be reduced by the invention. By this gliding, the color particles don't hook together or don't block, which otherwise would create a thicker and above all an irregular coating film. A positive

side effect is that the sound field in the

sump of a coating machine can destroy color lumps and / or can remove containing gases out of the coating color.

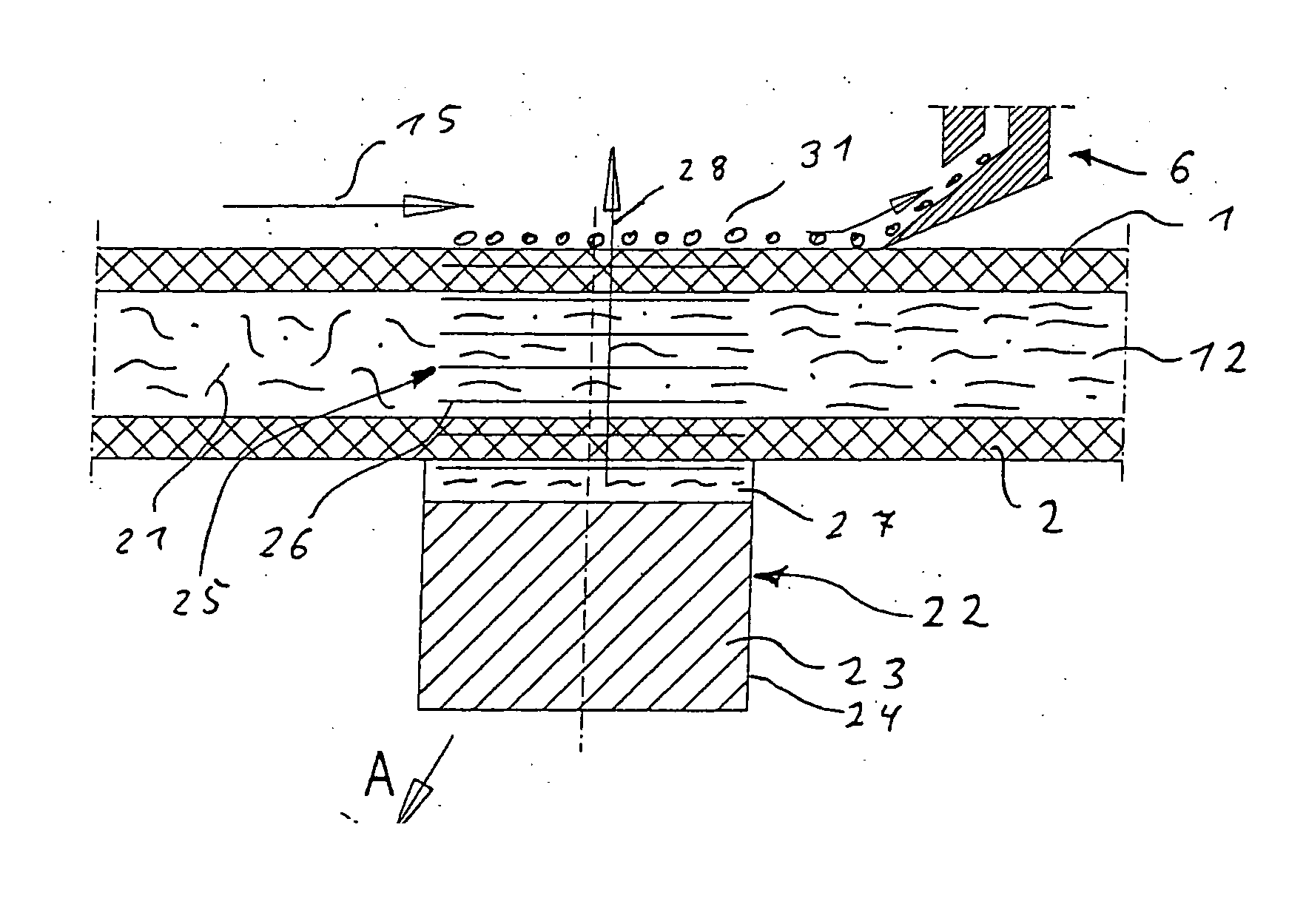

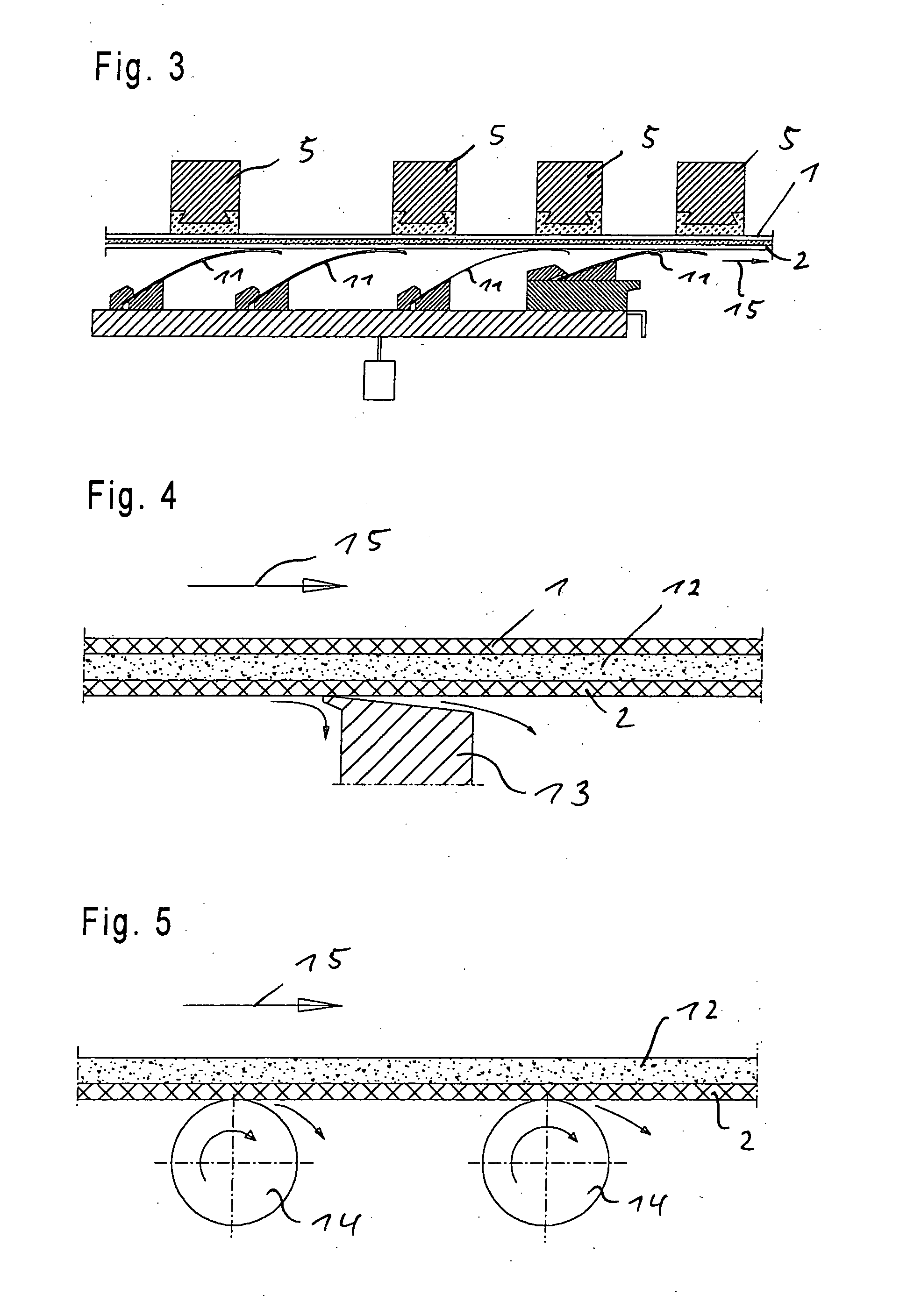

[0027] A further, very essential advantage of the invention is that the spreading speed of a sound field in a liquid amounts to nearly 1500 m / s, but the working speed of a modern paper machine is only 30 m / s. If a sound field, for example, has a width of 100 mm (in the running direction of the fiber web) and a frequency of 20,000 Hz, so the fibers are influenced by a total 67 vibrations in their run over the sound field. In comparison to the formers of the prior art with their limited number of slats (

dewatering ledges), the inventive use of the sound field presents a much higher number of pulses, wherein the pulses / vibrations not only influence the

dewatering, but also influence selectively the orientation of fibers and other particles. This just mentioned advantage can be heightened, if the chosen frequency is substantially higher. Because the inventive device—in view of the running direction—is very narrow, either it is possible to place the device between two slats or to place instead of few slats (dewatering ledges). So at least the number of ledges substantially remains the same.

[0028] The inventive sound fields are generated by an electric powered emitter. Every emitter consists of a

power unit and a housing. The drive is created by a coil, a magnetic

piston and a membrane or by piezo elements or the drive works on the magnetostrictive or capacitive principle. The surface of the

power unit which emits the sound field does generally has a parallel

stroke. Because the emitters are electrically driven, their power units can be designed by means of electro-technics and

electronics in manifold ways. By using a central

control unit, vibrations for each

power unit are individually adjustable. By superposition of vibrations, periodic pulses can also be generated. The vibrations will be defined, for example at the

control unit, in their amplitude, phase, frequency and energy. So that for every power unit a separate cable need not be laid, it is particularly advantageous, if the control occurs by means of a central data

bus. Because with a paper machine several kinds of paper will be produced and therefore a lot of production parameters are necessary, it is advantageous, if the parameters of the inventive device are stored in a

database of the

control unit. If production of a specific kind of paper with know parameters will be restarted, the parameters will be reloaded from the storage. Production costs are reduced due to this increased efficiency. Further it is advantageous if the control unit is linked to an online-measuring

system, for example, to a so called measuring frame.

Login to View More

Login to View More  Login to View More

Login to View More