Pouch opening feature

a pouch and opening technology, applied in the field of pouch opening, can solve the problems of considerable effort or motor control, inconvenient operation, and difficulty in finding cans or boxes requiring additional tools to open, and achieve the effect of reducing grip strength and pulling control, and simplifying the experience of opening a pouch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

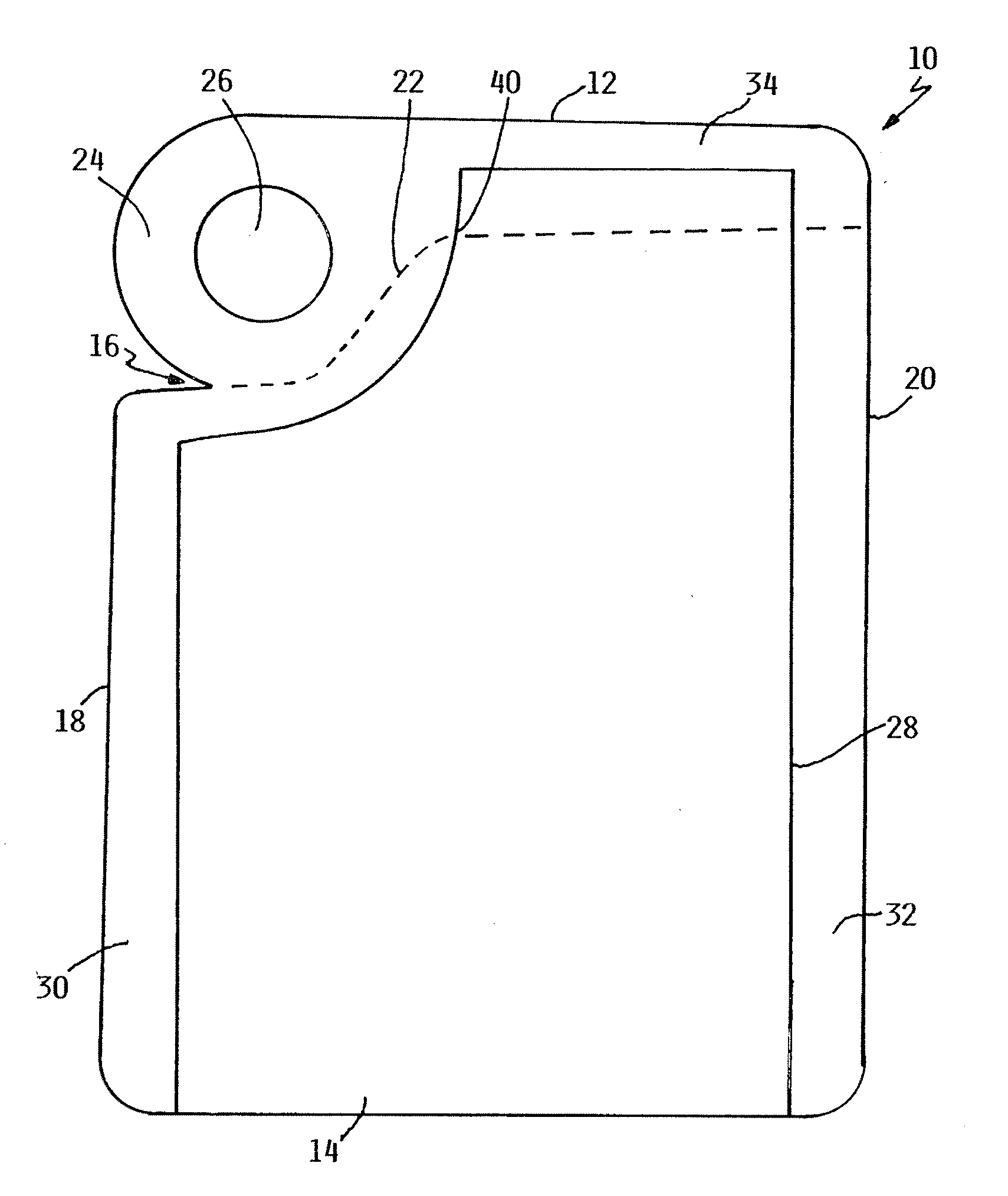

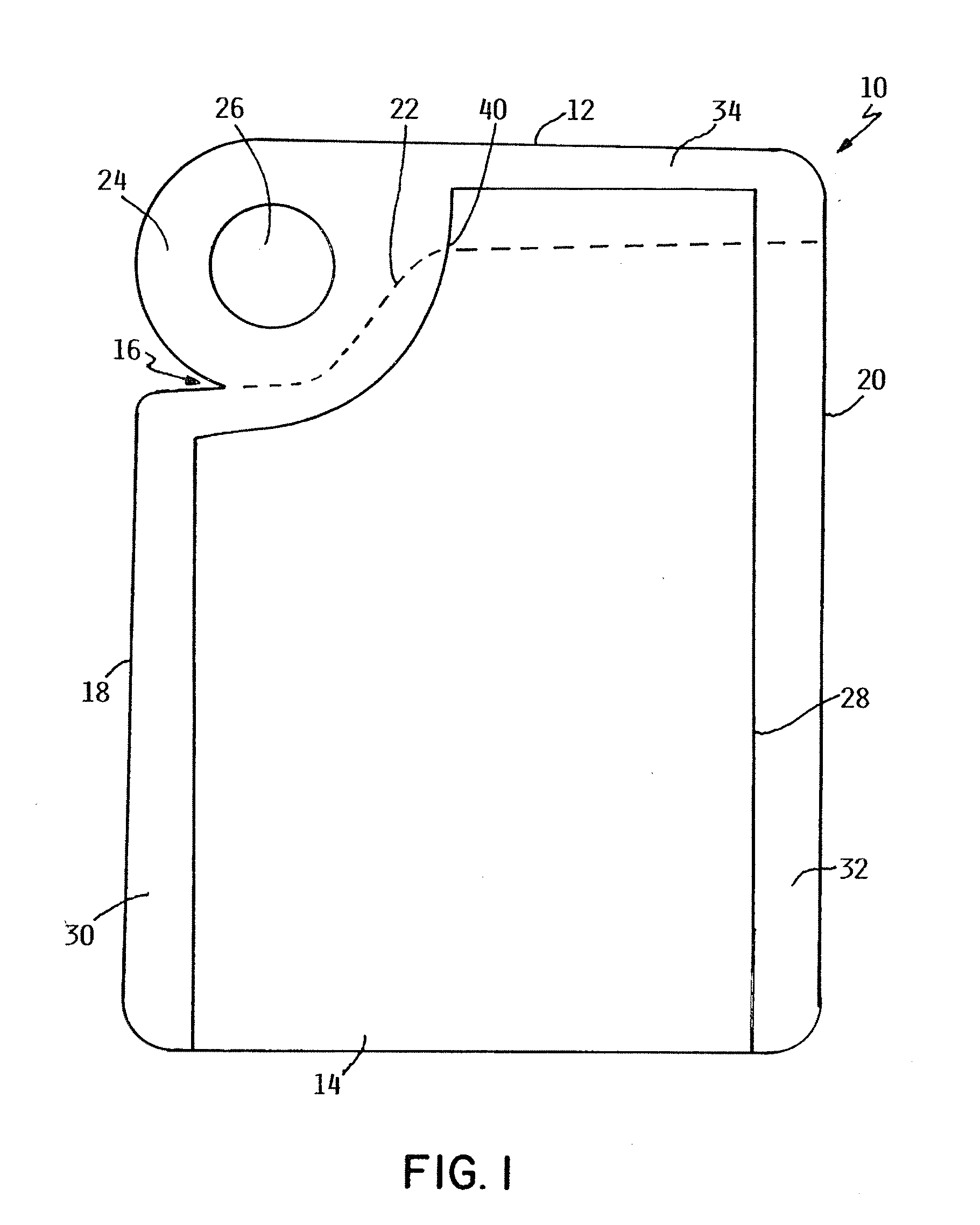

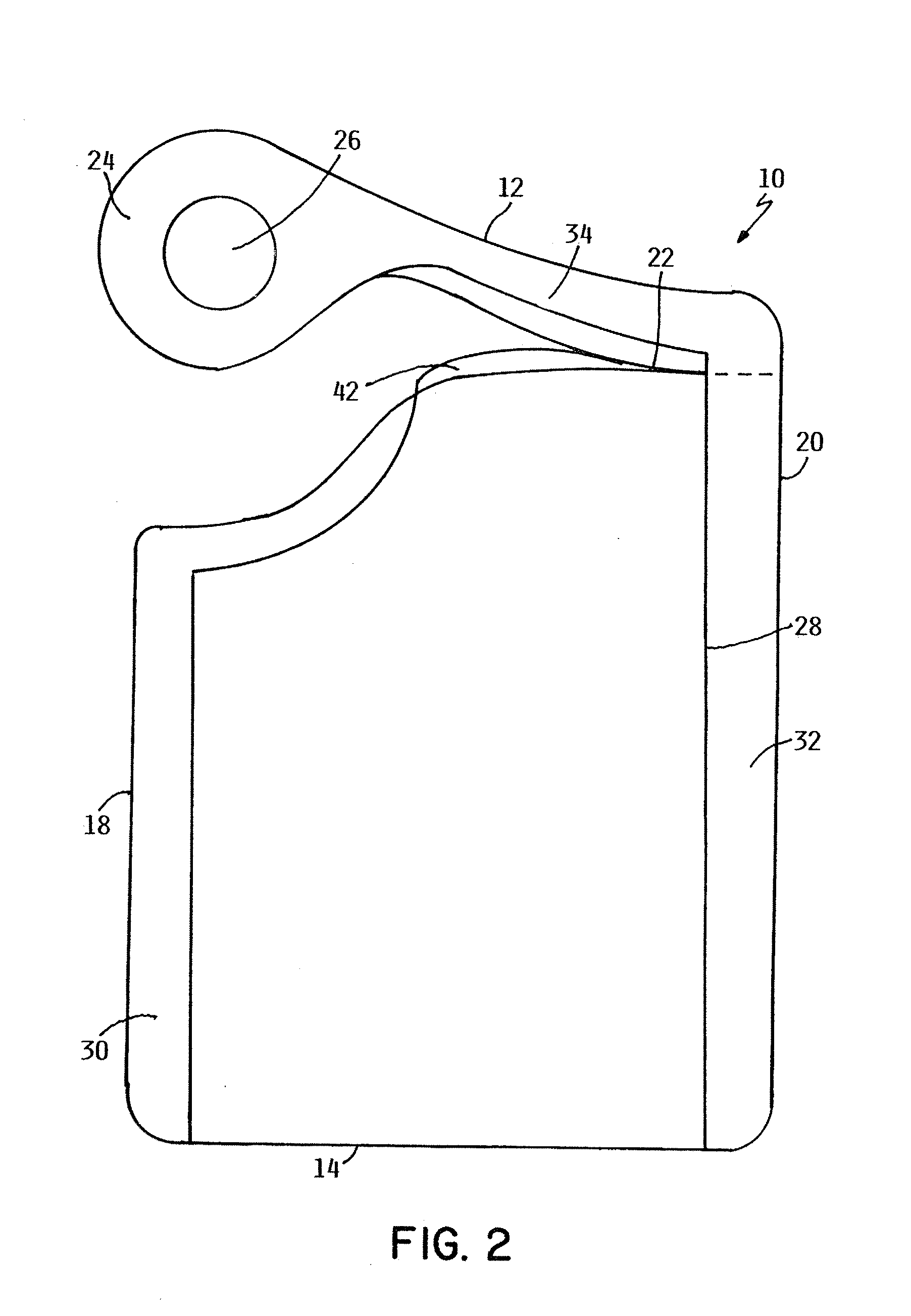

[0028] A pouch 10 in accordance with the invention is shown in FIG. 1. Pouch 10 relatively flat in profile, and is generally defined by a top end 12, a bottom end 14, a proximal edge 18, and a distal edge 20. A seal line 28 separates the interior of pouch 10 from the exterior of pouch 10 to form edge panel 30 and edge panel 32, and top edge panel 34, respectively.

[0029] In one embodiment, pouch 10 is fabricated from an integrally thermoformed plastic material, such as polyolefins (e.g., polypropylene, polyethylene), blends of polyolefins, polystyrene—HIPS, or polyester resin-based materials—CPET, foamed polypropylene, polyethylene), blends of polyolefin's polystyrene—HIPS, or polyester resin-based materials—CPET, paper and paper laminations with polypropylene, polyester, etc. In an alternative embodiment, pouch 10 may be fabricated using known injection molding, compression molding, and / or thermoforming techniques.

[0030] Tear notch 16 is disposed on pouch 10, between top end 12 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tear-open resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com