Distributor Indexing Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

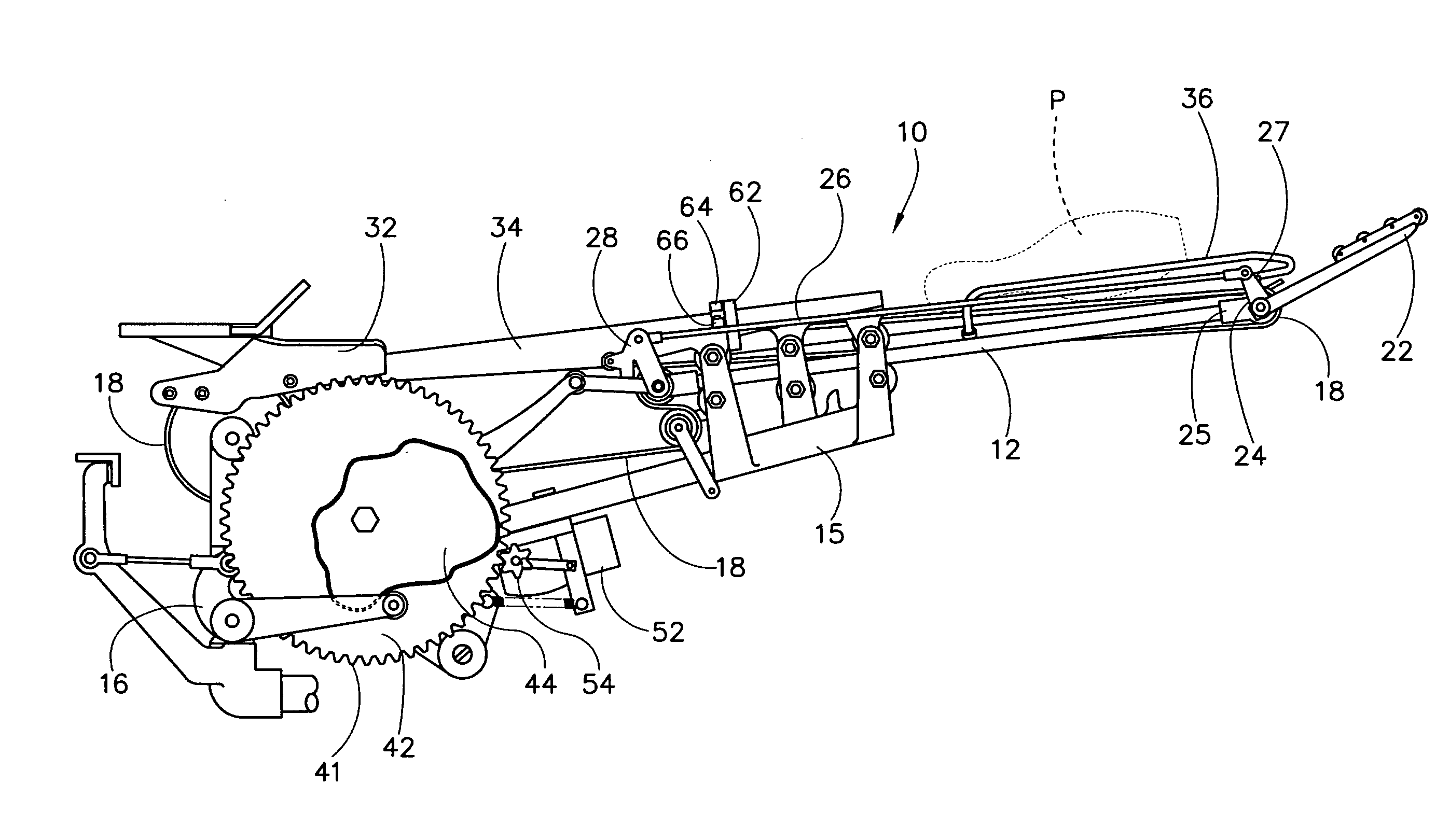

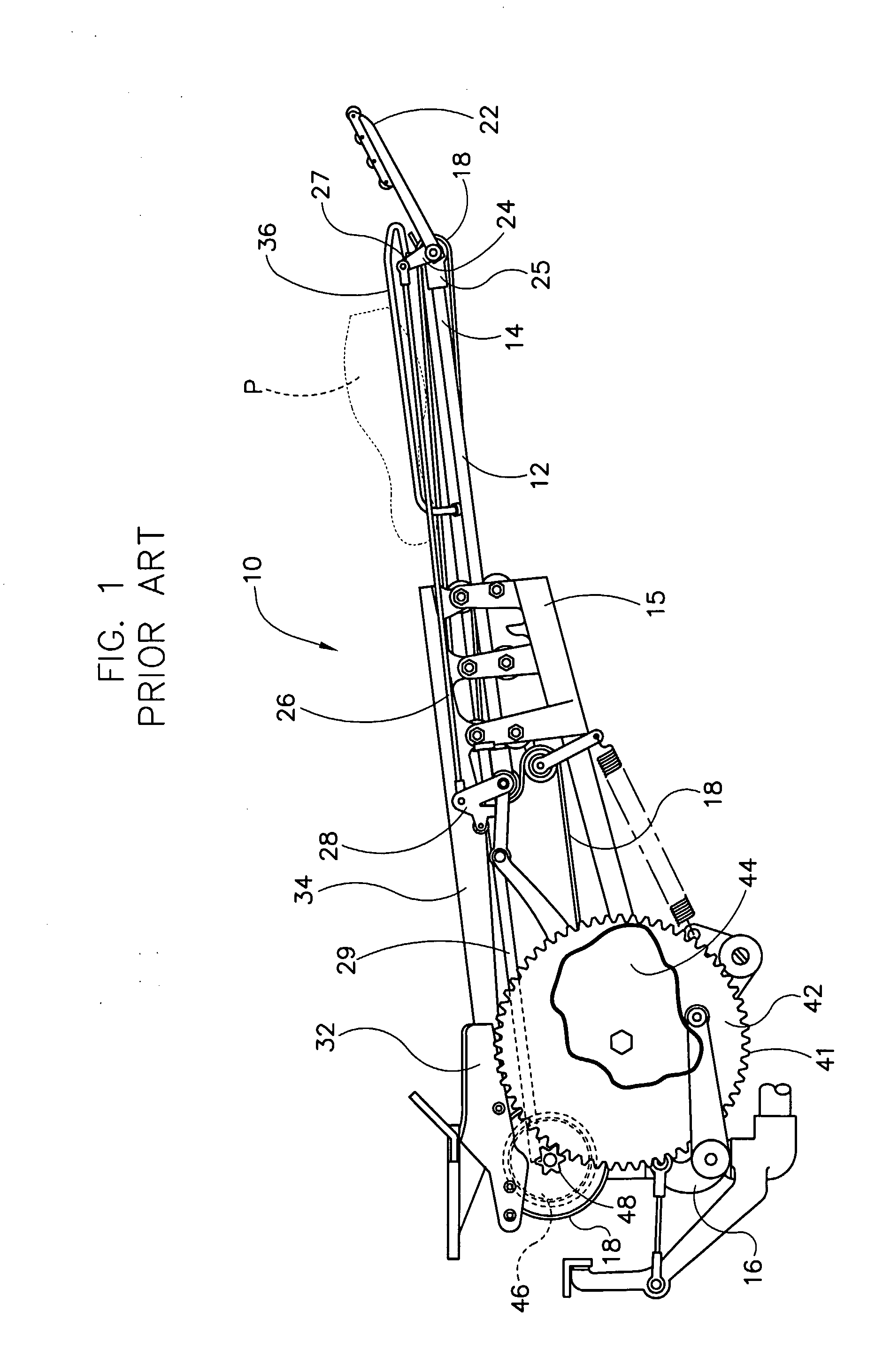

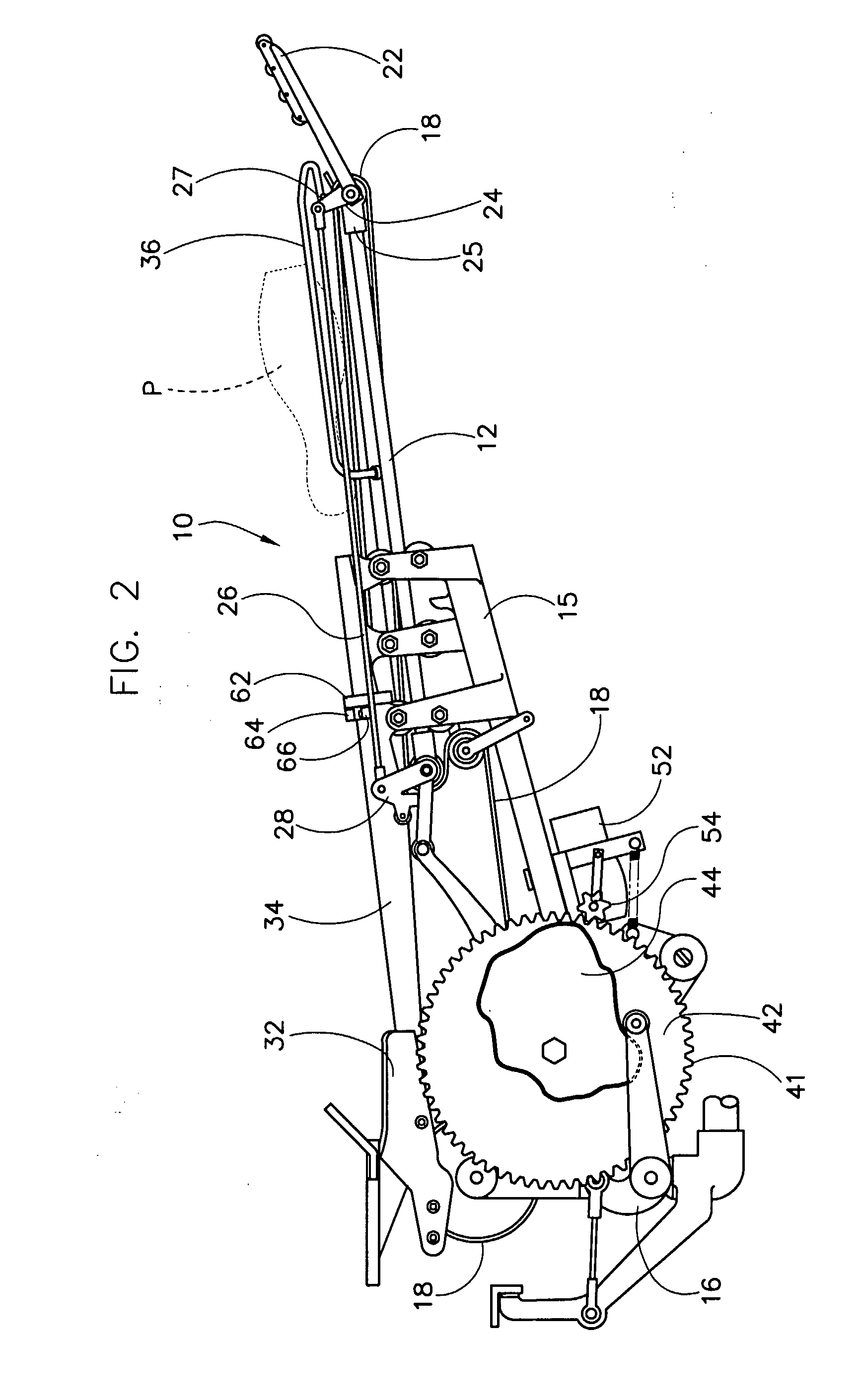

[0017]Referring now to the drawings in detail wherein like numbers represent like elements throughout, FIG. 1 illustrates a side elevational view of a bowling pin distributing mechanism, generally identified 10, that is constructed in accordance with the prior art. The distributing mechanism 10 shown is essentially the same in construction and operation as element D shown in U.S. Pat. No. 3,526,401, which is described in substantially greater detail starting at Col. 3, Line 64 to Col. 7, Line 47 thereof and which is incorporated herein by reference, but with element numbers as assigned herein. For brevity, the essential elements and function of the distributing mechanism 10 will be presented here for purposes of understanding the relation between component parts that remain the same in the preferred embodiment of this invention, as well as those that are replaced by it.

[0018]As shown, the distributing mechanism 10 includes a boom 12 having a proximal portion 16 and a distal portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com