Two-piece ball bat with rigid connection

a two-piece ball bat and rigid connection technology, applied in the field of ball bats, can solve the problems of poor material for the player's hands to hold and grip, difficulty in manufacturing mechanical joints, and common problems in the barrel region to achieve the effect of providing durability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

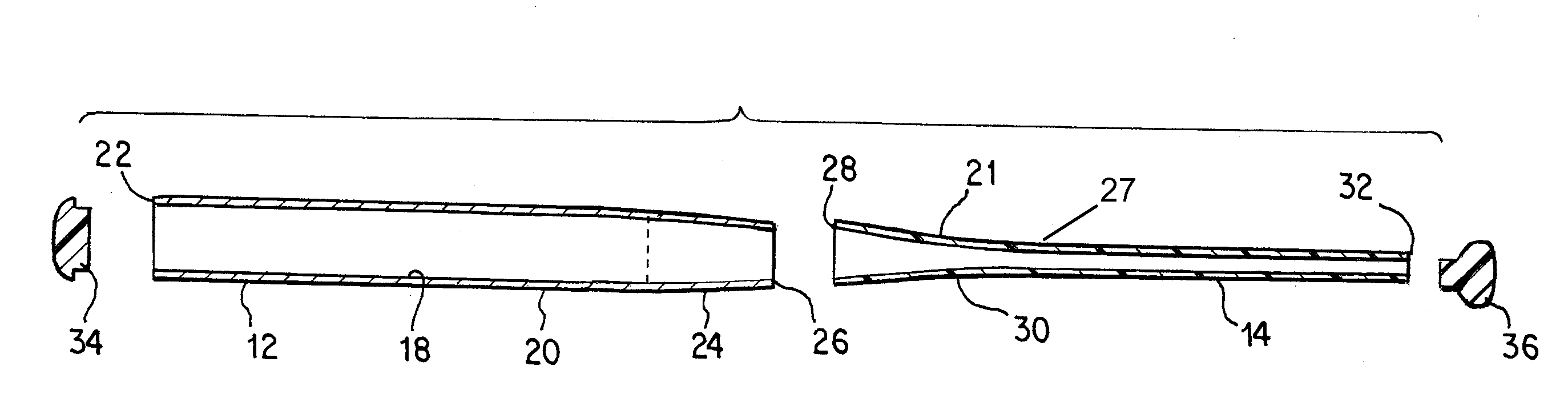

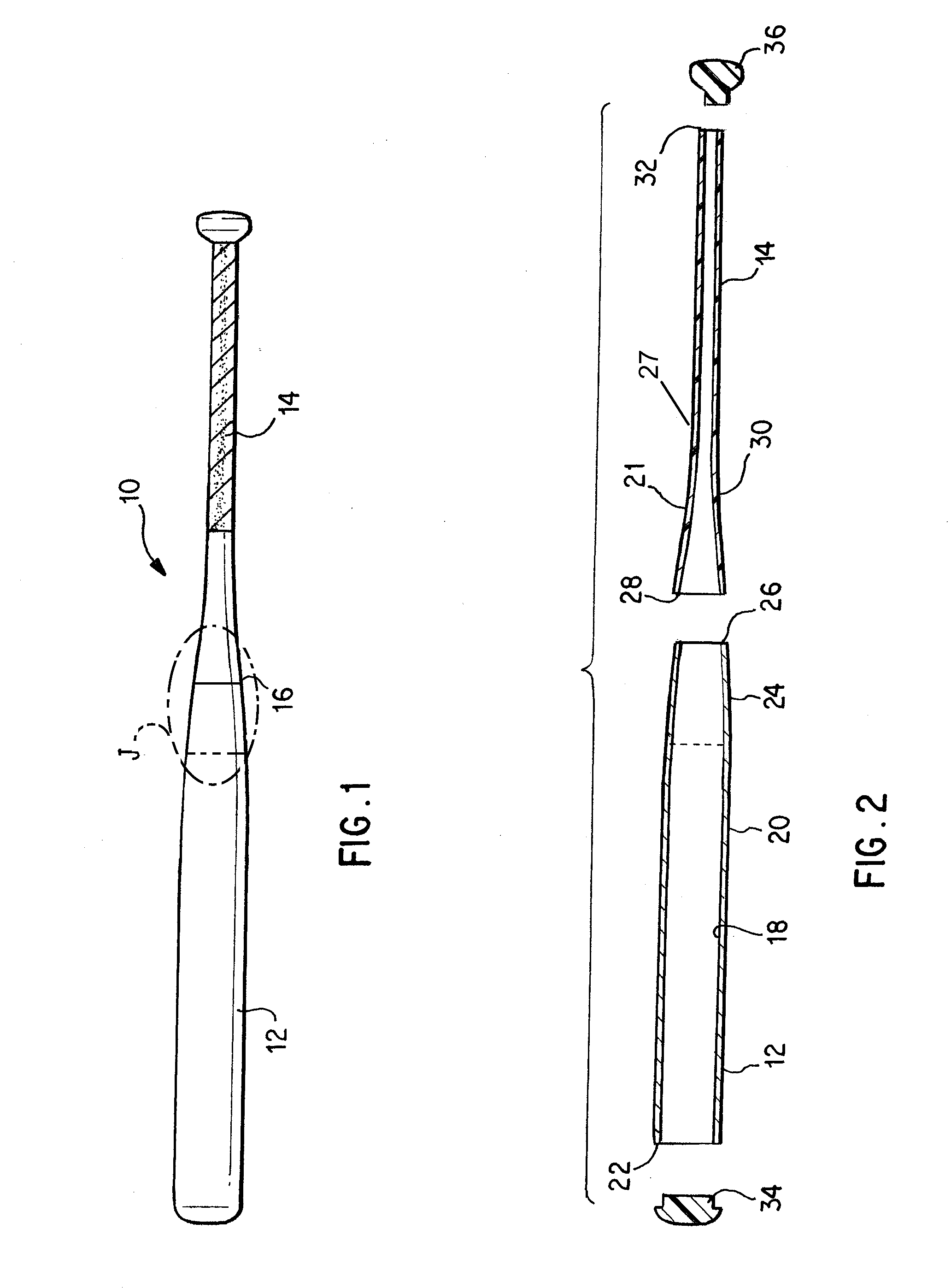

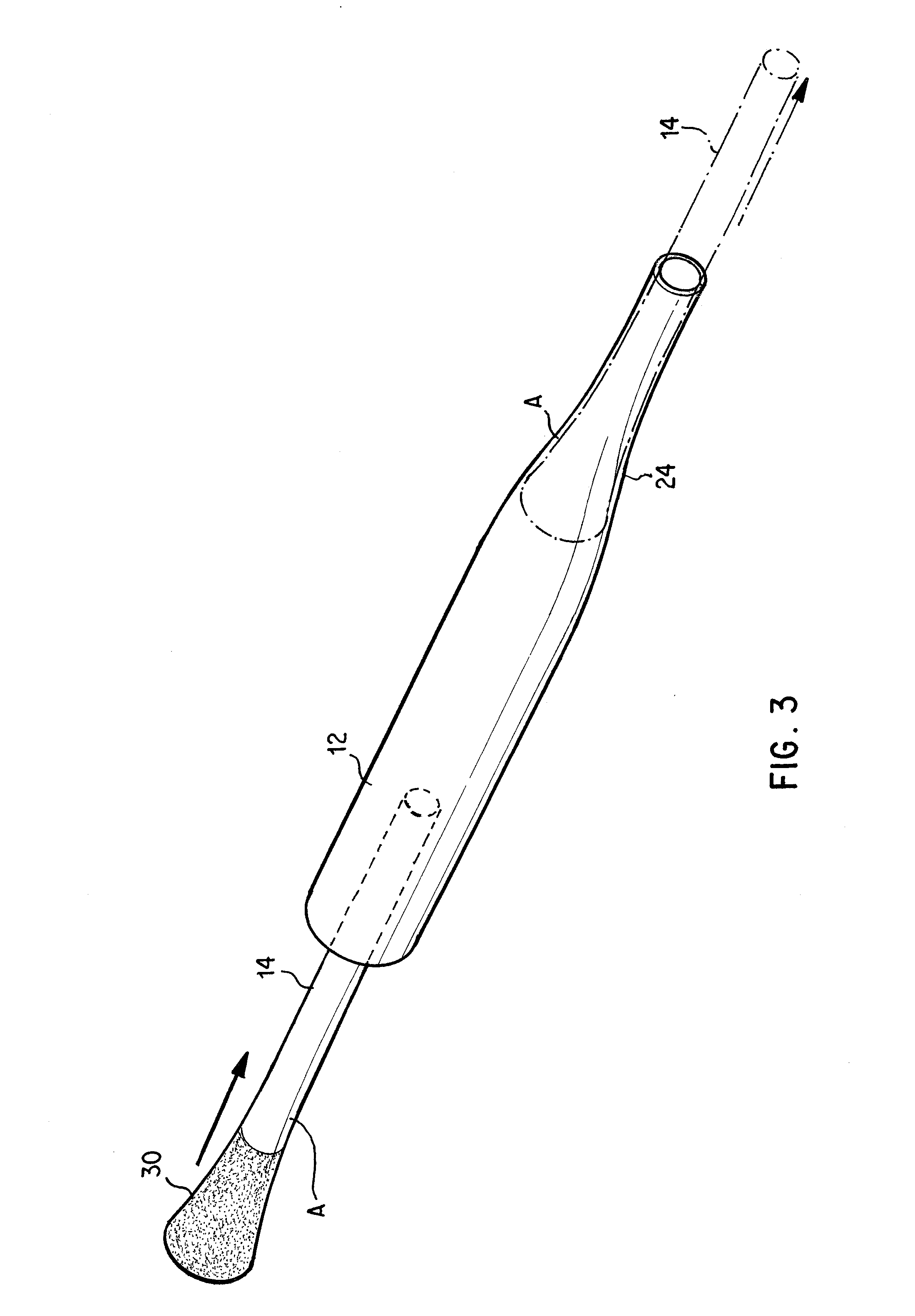

[0024]FIG. 1 shows assembled ball bat 10 comprising a barrel 12 and a handle 14 attached to one another at a taper junction 16. Taper junction 16 is the transition between the larger circumference barrel and smaller circumference handle. FIG. 2 shows in exploded cross-section the components of the ball bat. Specifically that barrel 12 is a hollow body with an interior surface 18 and an exterior surface 20. Along its length barrel 12 has a distal free end 22, a taper section 24, and a proximal joint end 26. Barrel 12 has a larger diameter at its distal free end 22 and a smaller diameter at its proximal joint end 26. Taper section 24 provides a smooth transition between these two circumferences. Exterior surface 20 of the barrel is the ball contact surface. Handle 14 is shown in FIG. 2 to be a hollow body, but could be solid. Handle 14 has an exterior surface 27 and includes along its length, proximal joint end 28, a taper section 30 and a distal free end 32. Joint end 28 of handle 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com