Beverage cup sleeving system and method

a beverage cup and sleeve technology, applied in the field of conical sleeves, can solve the problems of poor thermal insulation of biodegradable huts, soup, coffee, tea, etc., and achieve the effects of improving thermal insulation, reducing the difficulty of sleeve replacement, and improving thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

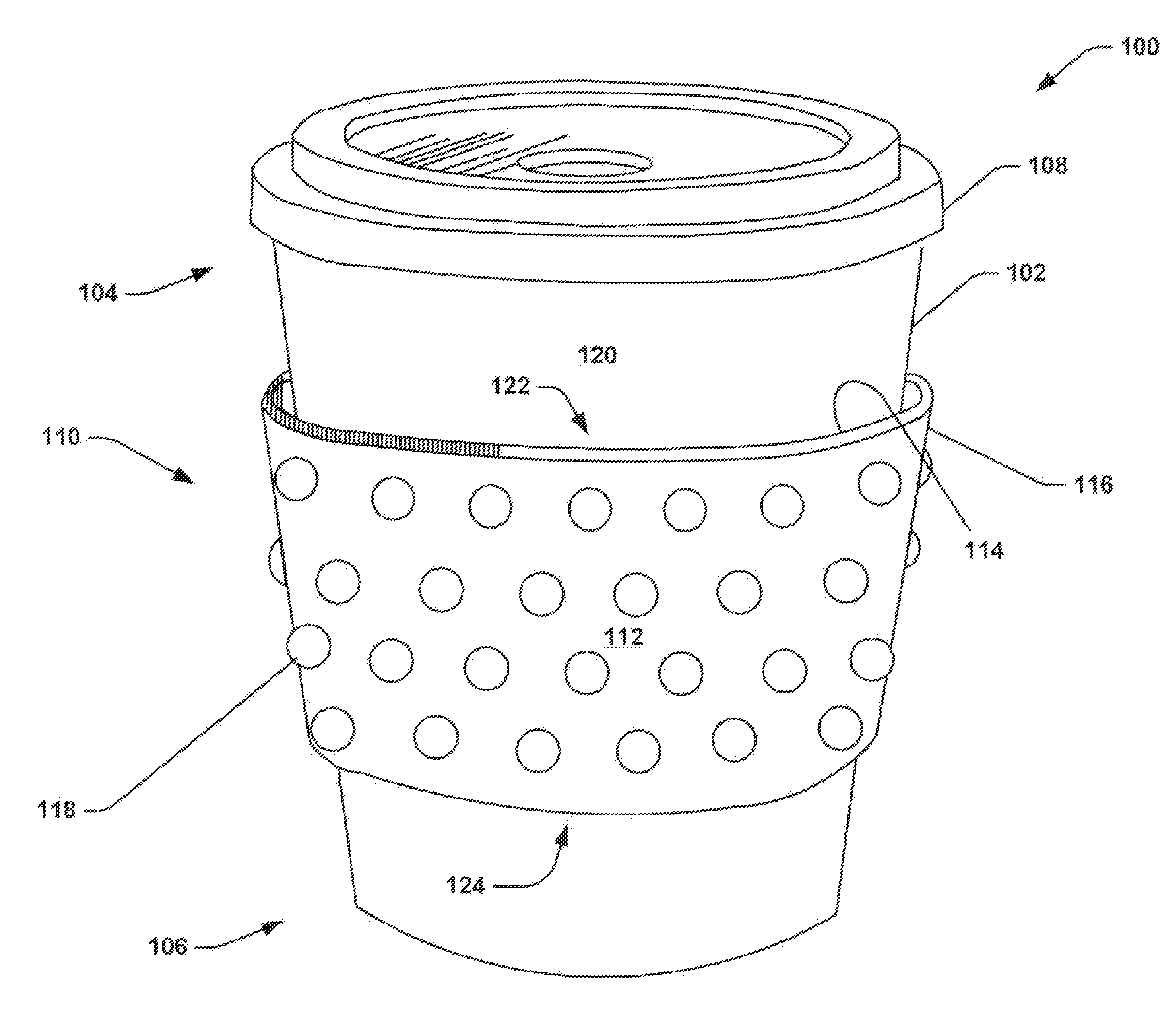

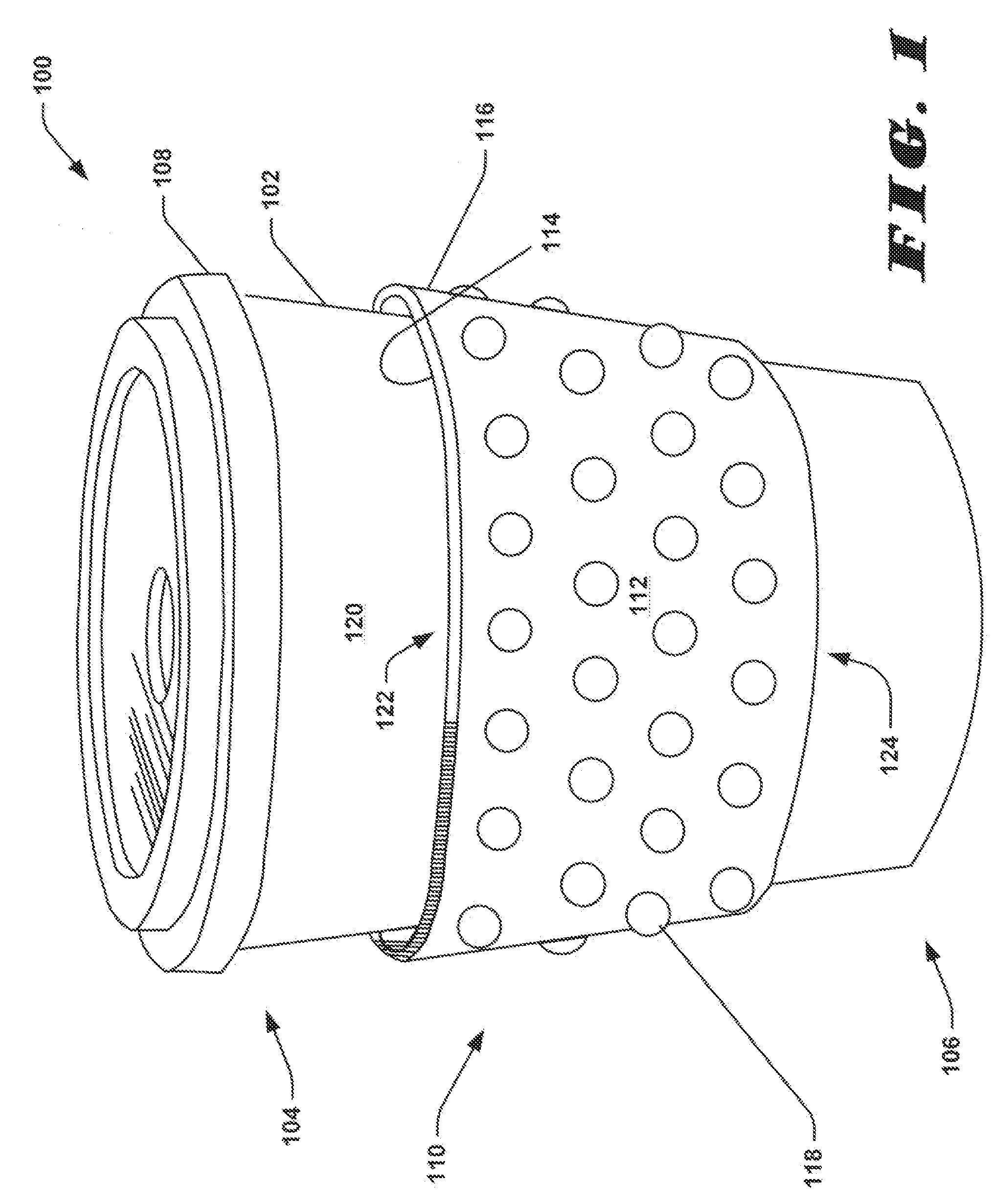

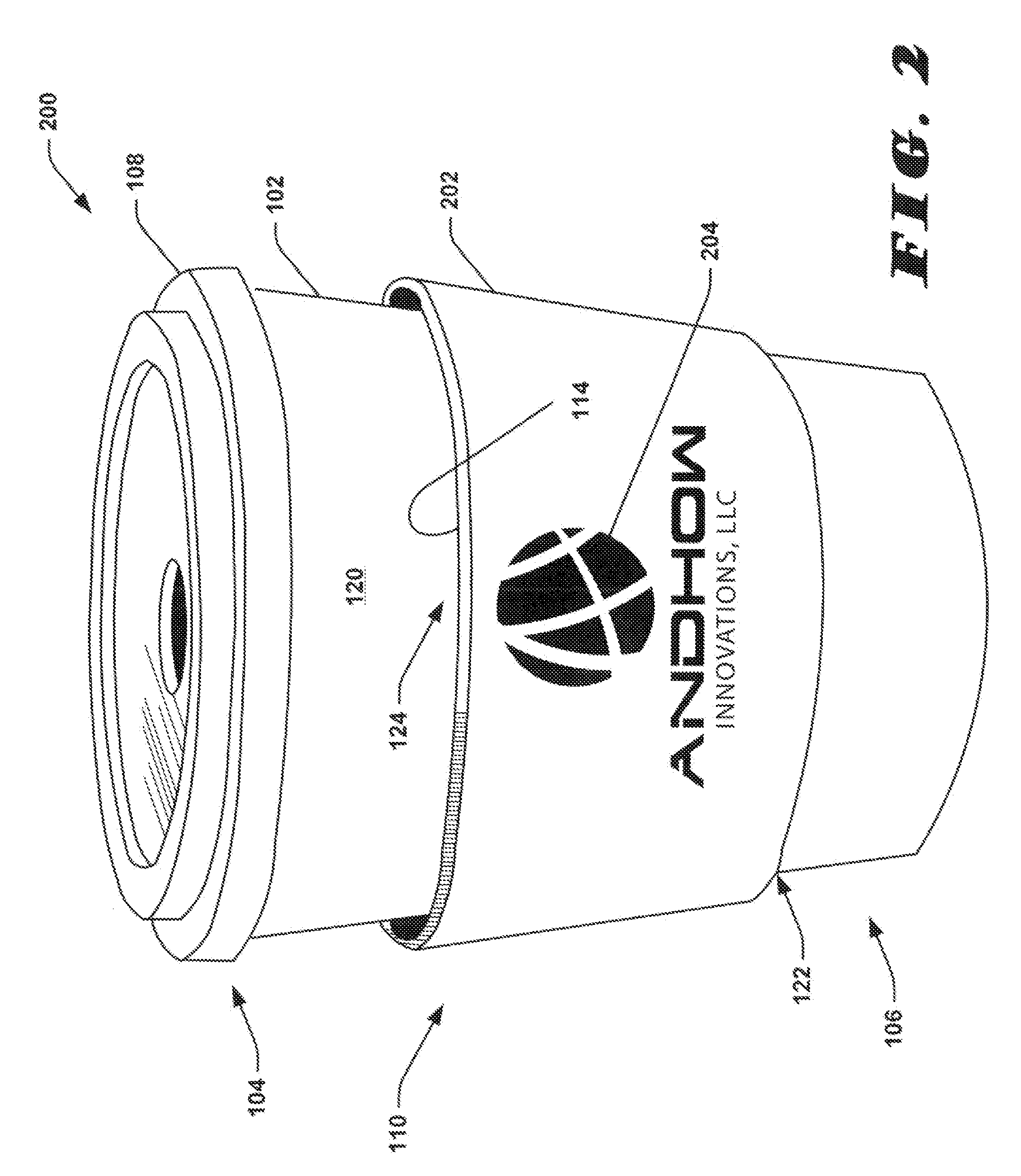

[0023]One or more implementations of the present invention will now he described with reference to the attached drawings, wherein like reference numerals are used to refer to like elements throughout. The invention relates to a beverage cup sleeving system and associated method wherein a reusable coffee cup sleeve can be fitted over hot or cold beverage cup.

[0024]Referring now to the figures, FIG. 1 illustrates a coffee cup sleeving system 100, wherein a disposal hot beverage or liquid cup 102 can be held within an insulating elastomeric sleeve assembly 110, as shown. The cup 102 can be formed of paper, paperboard and the like, and has a wider top portion 104 and a smaller diameter bottom portion 106. While the beverage cup 102 illustrated can be made of paper, cellulose material, and the like, it may also be made of any suitable plastic, for example, Styrofoam. The lid 108 employed is typically manufactured in plastic, such as polystyrene.

[0025]The sleeve assembly 110, can be slid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com