Building Methods

a building method and building technology, applied in the direction of structural elements, building components, load-supporting elements, etc., can solve the problems of increasing material and construction costs, adversely affecting the dynamic response of the building, and requiring a corresponding increase in the foundation of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

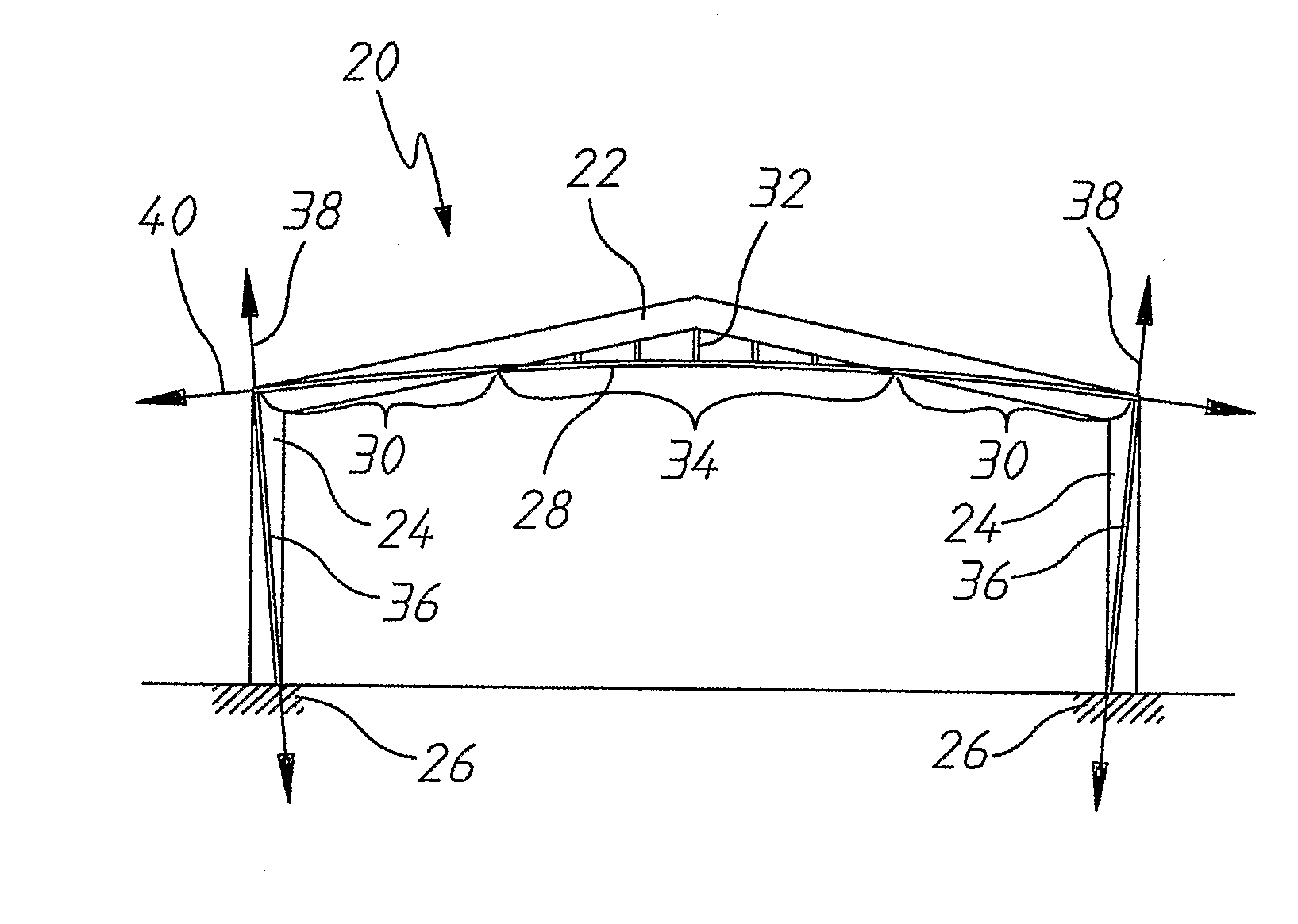

[0038]FIG. 1 shows a (non-steel) portal frame structure 20 formed from a centre span 22, two columns 24 and two foundations 26. Each half of the centre span 22 and each of the columns 24 represent a sub-structure of the steel portal frame structure 20.

[0039]The centre span 22 has a first cable retainer 28 attached thereto, by welding in the regions 30 and via the struts 32 in the region 34. Each of the columns 24 also have cable retainers 36 attached thereto by welding.

[0040]Cables, represented by double headed arrows 38 and 40, are passed through the cable retainers 28 and 36 respectively. The cables 38, 40 are tensioned relative to the cable retainers 28, 36 respectively then bonded to the cable retainers 28, 36 respectively, prior to releasing the tension in the cables. The tensioning, bonding and releasing steps shall be described in more detail below.

[0041]The cable retainers 28, 36 extend generally along the longitudinal direction of their associated centre span (sub-structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com