Compressible Thin-Walled Package For Liquids

a thin-walled package and liquid technology, applied in the field of packaging, can solve the problems of insufficient rigidity of the whole bottle, prolonging the bottle, and the bottle cannot be compressed in the axial direction, so as to reduce the compression force, improve the definability or predictability of deformation, and avoid the risk of creating folds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

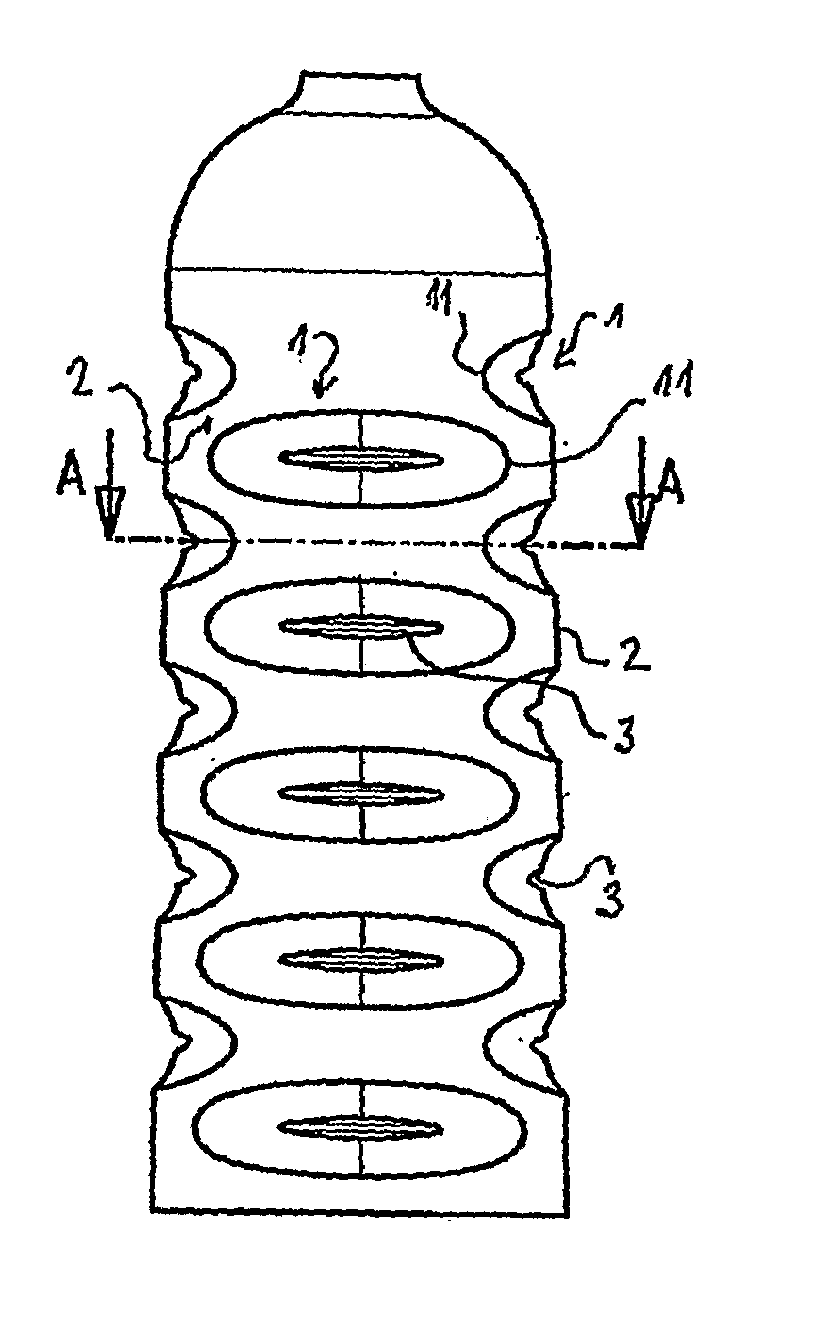

[0016] A thin-walled compressible package in accordance with the submitted invention is designed as a plastic bottle with transversal recesses 1 while the recesses 1 are arranged in ten layers and in each layer there are two recesses 1. Along the package, i.e. along the bottle in this case, the axes of the recesses 1 always follow the axis of the gap between the recesses 1 created in the neighbouring layers while at the same time the side margins 11 of the recesses 1 in the neighbouring layers partly overlap each other with regard to the longitudinal axis of the package from the axial point of view. This way an area 2 without recesses is formed on the surface of the bottle that is resistant to tensile forces when the bottle is under pressure. The mutual overlapping of the margins 11 of the recesses 1 in individual layers facilitates deformability of the bottle during its compression, but does not substantially weaken the tensile strength of the bottle. More recesses 1 may be advanta...

example 2

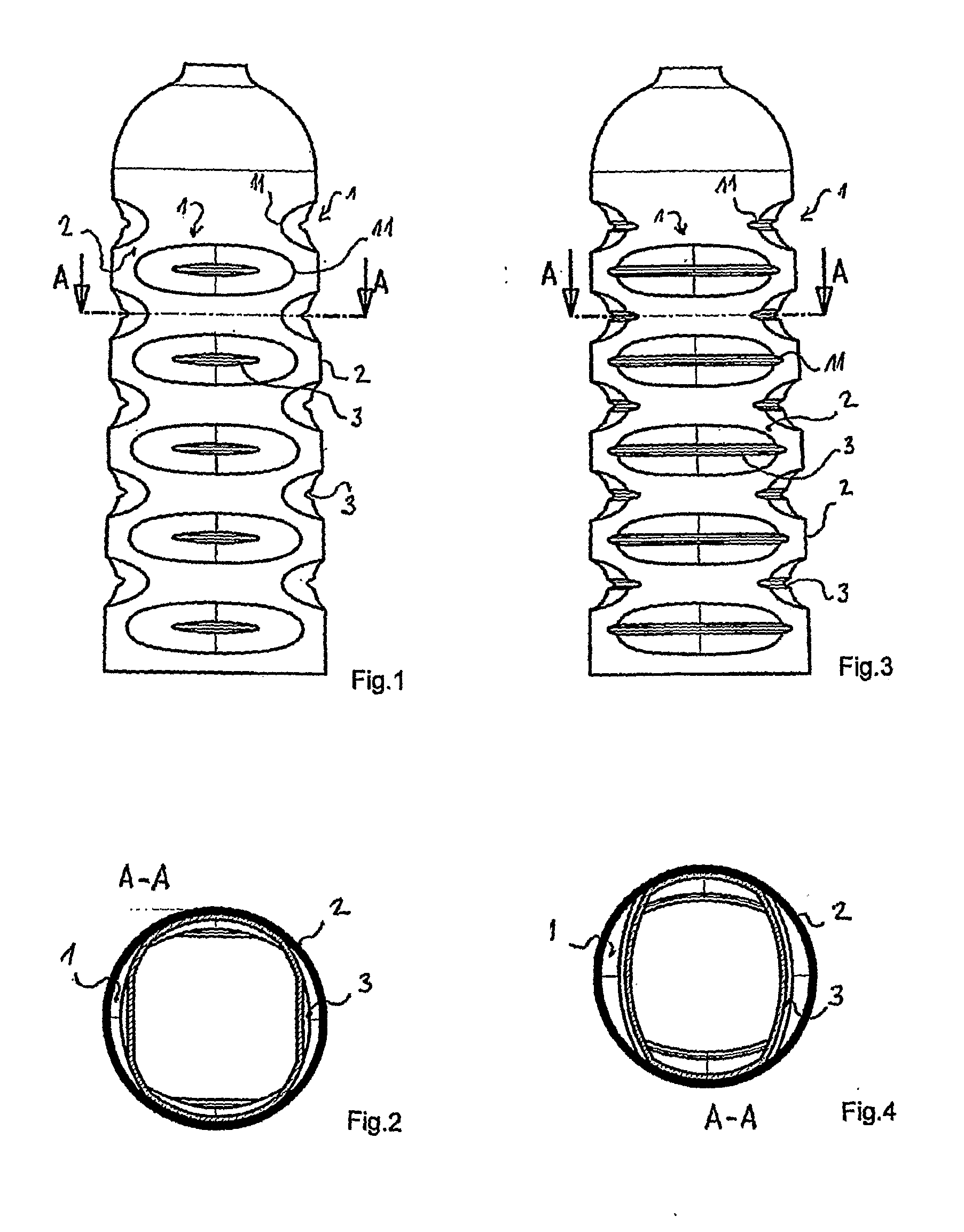

[0018] This is a similar design as in sample 1 with the difference that in the recess 1 long auxiliary recesses 3 are created that run all along the length of the main recesses 1. This design is shown in FIG. 3 and FIG. 4.

example 3

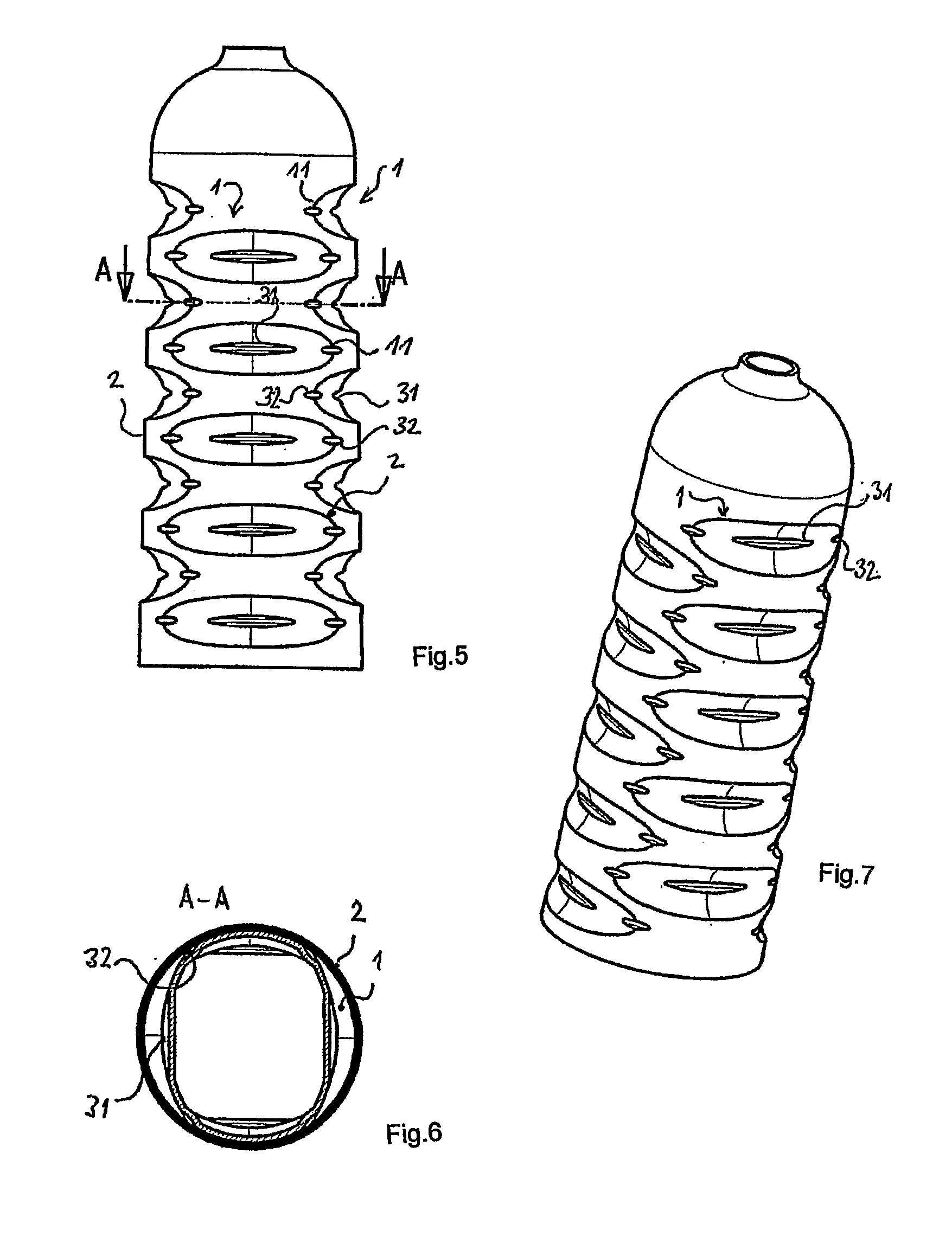

[0019] The design is similar to samples 1 and 2 while in each recess 1 there are always three auxiliary recesses 3, where one central recess 31 is in the same position as in sample 1 and is complemented with two short auxiliary recesses 32 at the margins 11 of the main recess 1. This design is shown in FIG. 5 and FIG. 6 and also in FIG. 7 in a perspective view.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap