Apparatus and method for handling particulate material

a technology of particulate material and apparatus, which is applied in the direction of movable measuring chambers, instruments, packaged goods, etc., can solve the problems of difficult operation and cleaning, large space occupation, and high cost, and achieve the effect of reducing the weight of the load cell, fast and automatic monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

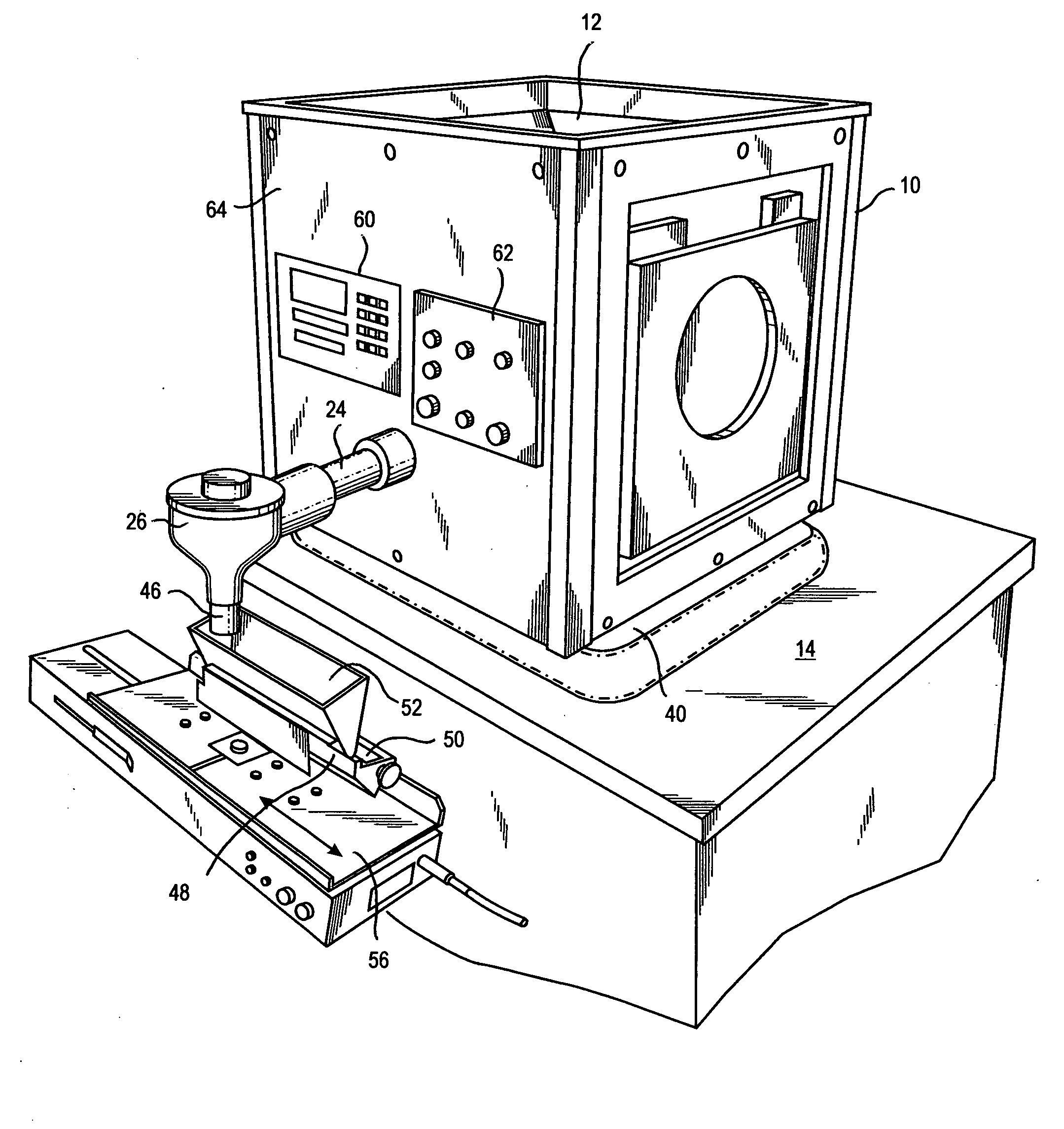

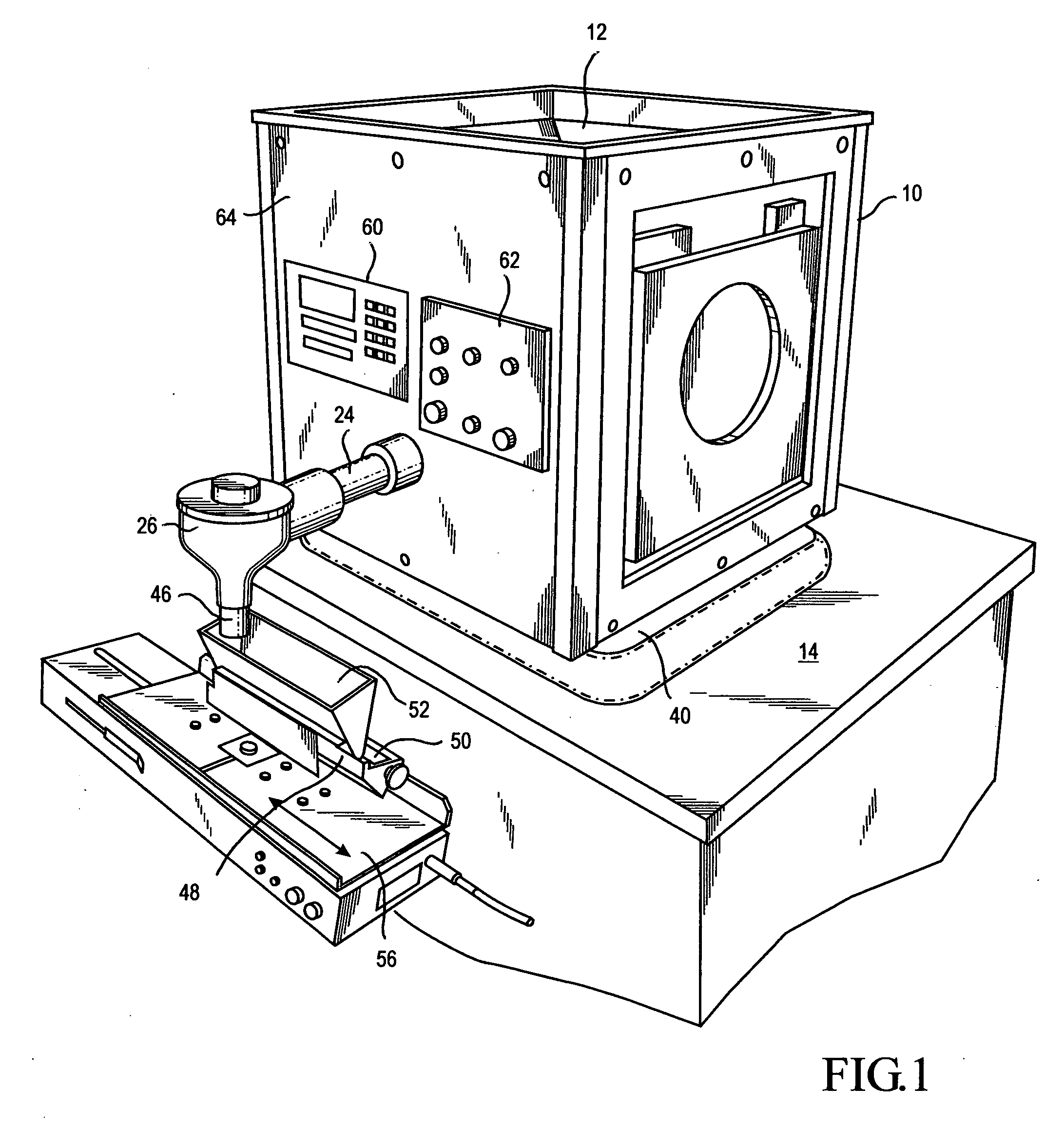

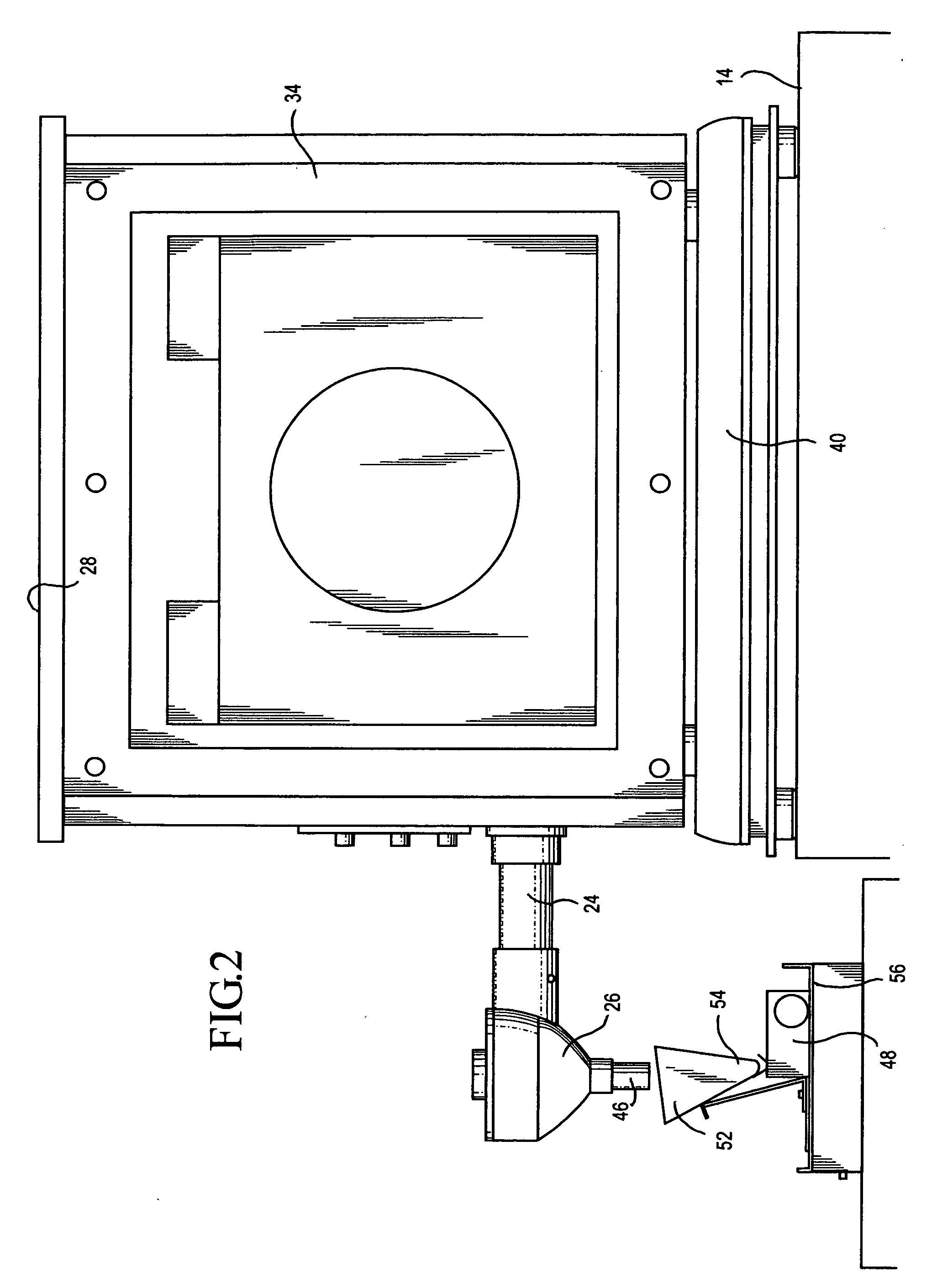

[0016]Referring to FIGS. 1-3, the illustrated embodiment of the invention comprises an outer housing 10, a hopper 12 within the housing 10 and a supporting structure 14 shown in the form of a countertop. The hopper 12 has an upper end 16, a lower end 18 and a downwardly tapering sidewall 20. A trough 22 is provided at the lower end 18. A discharge passageway 24 extends endwise outwardly from one end of the trough 22 to a downwardly opening outlet spout 26 that is outside of the housing 10. As shown by FIG. 3, the sidewalls of the hopper 12 converge as they extend downwardly. Hopper 12 is connected to the housing 10 at any suitable manner. Preferably, a lid 28 is provided for the housing 10 and the hopper 12. In FIG. 1, the lid 28 is removed. In FIG. 3, the lid 28 is installed.

[0017]An elongated helical feed screw 26 is positioned in the trough 22. One end of the feed screw 26 extends through the outlet passageway 24 over to where the outlet passageway 24 connects to the discharge sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| plastic | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com